Quantitative evaluation method for measuring corrosive sulfur by X-fluorescence

A corrosive sulfur, quantitative evaluation technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of inaccurate qualitative analysis, increased technical difficulty, subjectivity, etc., to avoid misjudgment and reduce misjudgment of corrosiveness Sulfur, the effect of strong operational practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

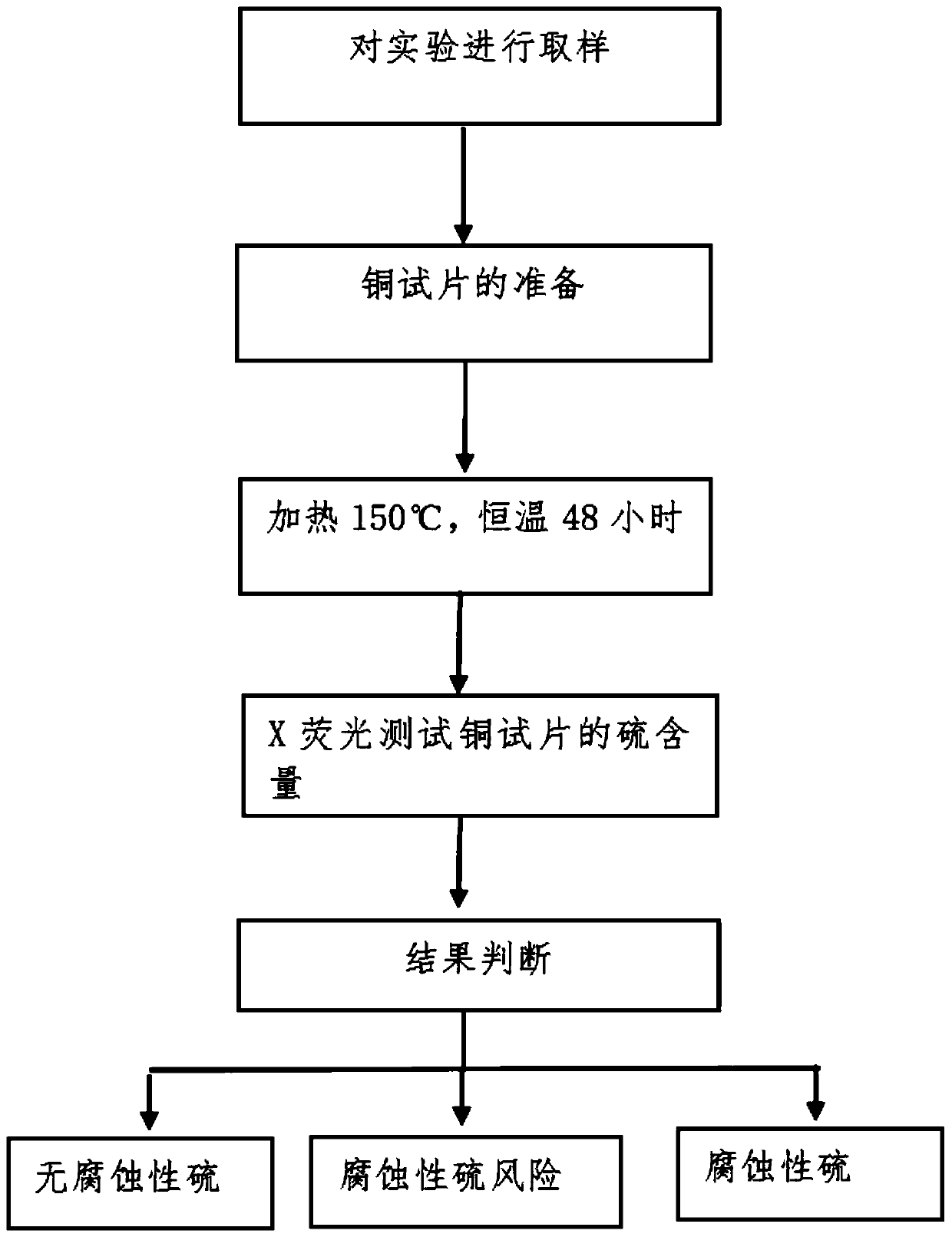

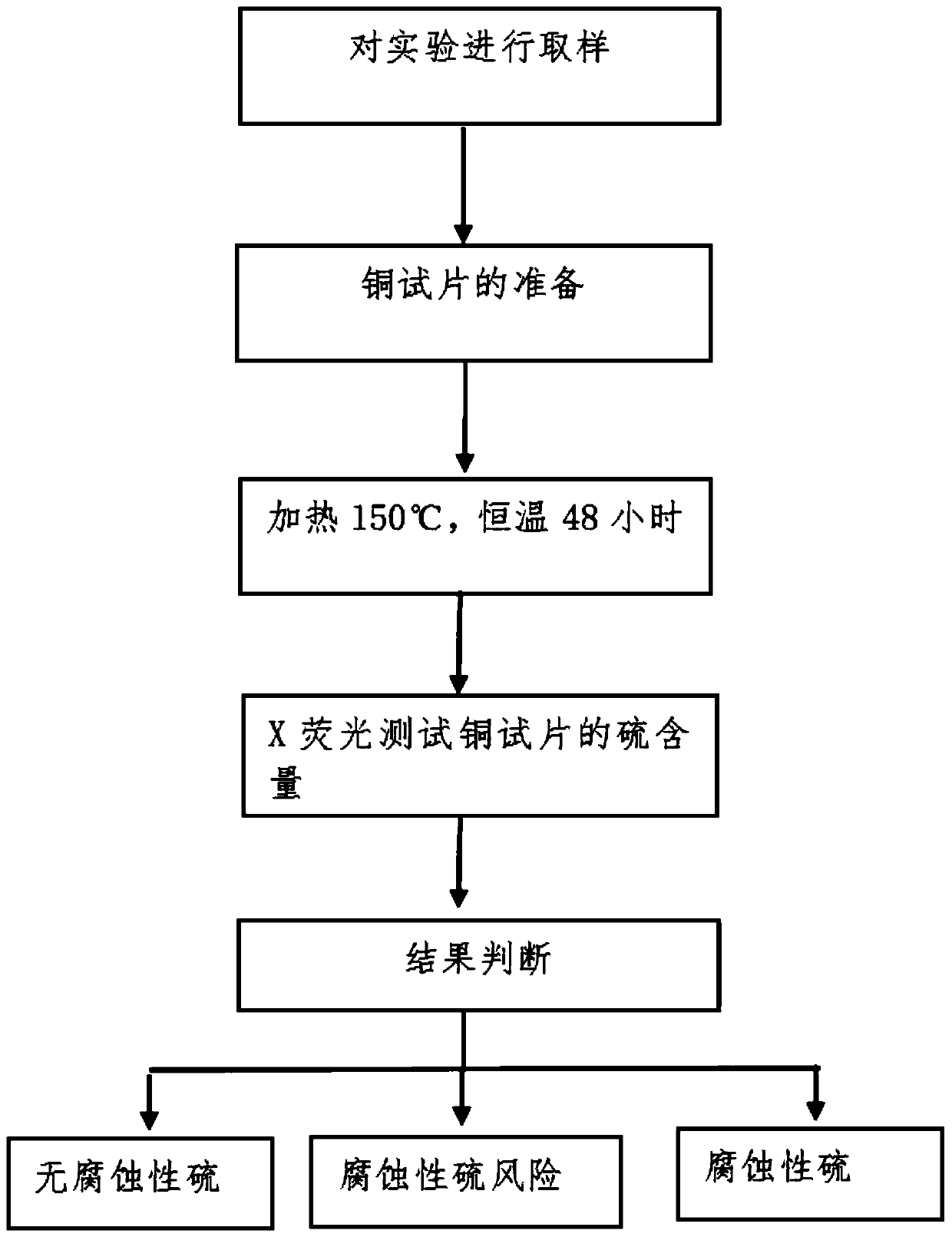

[0042] A kind of quantitative evaluation method of measuring corrosive sulfur by X fluorescence of the present invention, described method comprises the following steps:

[0043] 1) Use a 100mL graduated cylinder to take 15mL uniform sample and put it into a 20mL headspace bottle;

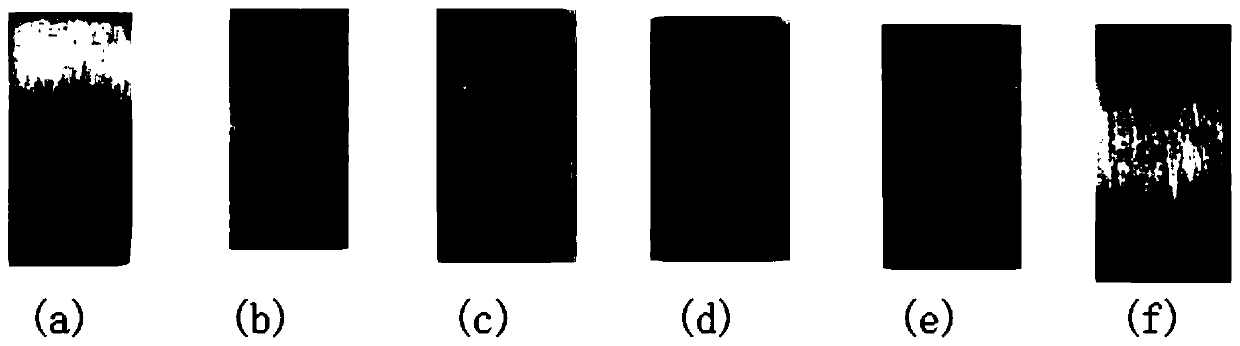

[0044] 2) Polish the copper test piece samples a, sample b, sample c, sample d, sample e, and sample f with 240-mesh sandpaper respectively, and clean them with petroleum ether III, and use an X fluorescence sulfur meter to detect whether the copper test piece contains Sulfur, without sulfur, put the copper test piece into the container where the sample has been taken, ensure that the copper test piece is completely immersed in the oil, and cover the metal cover with rubber gasket;

[0045] 3) Open the oven in advance, set the temperature at 150±3°C, and keep the temperature constant for more than 30 minutes, put the above container in the oven at 150°C±3°C, keep the temperature constant for 24h or...

Embodiment 2

[0053] The precision (repeatability) of embodiment 2 method

[0054] In the same experiment, the same test product is carried out according to the method of embodiment 1 by the same experimenter, and the experiment is repeated at least 6 times to investigate the repeatability of the method. The results are as shown in table 2:

[0055] Table 2

[0056]

[0057] As can be seen from Table 2, the precision of the X fluorescence test corrosive sulfur quantitative analysis method of the copper test piece of the present invention is 13.8%, as seen this method precision is high, and repeatability is good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com