Fuel adjusting system for heating furnace, fuel adjusting method and heating furnace

A technology for fuel conditioning, heating furnaces, applied in the field of chemical engineering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

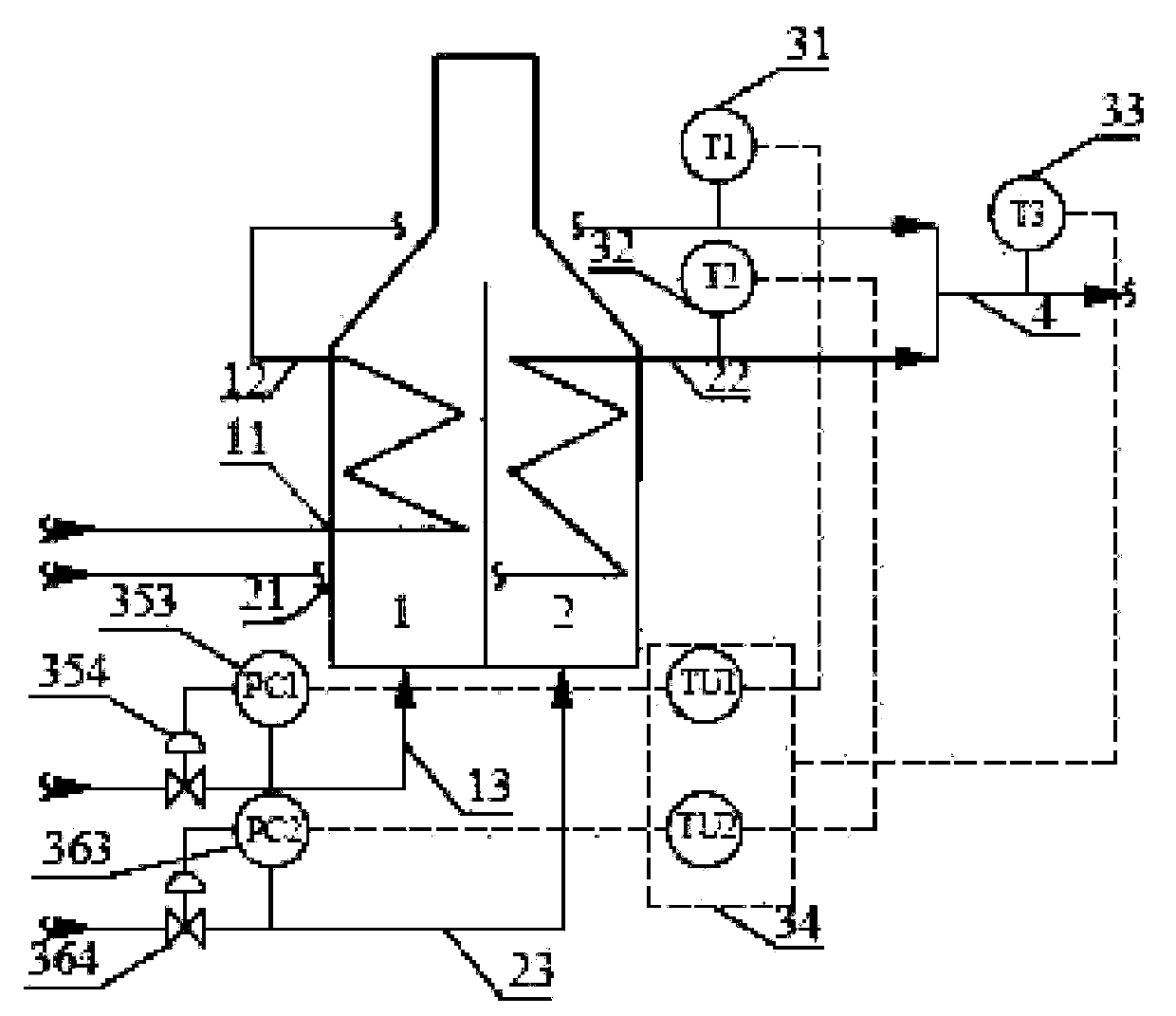

[0083] A hydrocracking unit with a processing capacity of 2.5 million tons per year and a single series. Due to the large processing capacity, the heating furnace is designed as two-way feed, the upstream process feed pipeline of the heating furnace is arranged according to two natural symmetrical distributions, and the downstream of the heating furnace is connected to the hydrogenation reactor.

[0084] The heating furnace includes a first furnace 1, a second furnace 2, a fuel regulating system and a mixing main pipe 4. The first furnace 1 is provided with a first material inlet 11, a first material outlet branch 12 and a first fuel inlet. Material branch 13, the second furnace 2 is provided with a second material inlet 21, a second material outlet branch 22 and a second fuel feed branch 23, the first material outlet branch 12 and the first After the two material outlet branches 22 are merged, the mixing main pipe 4 is set;

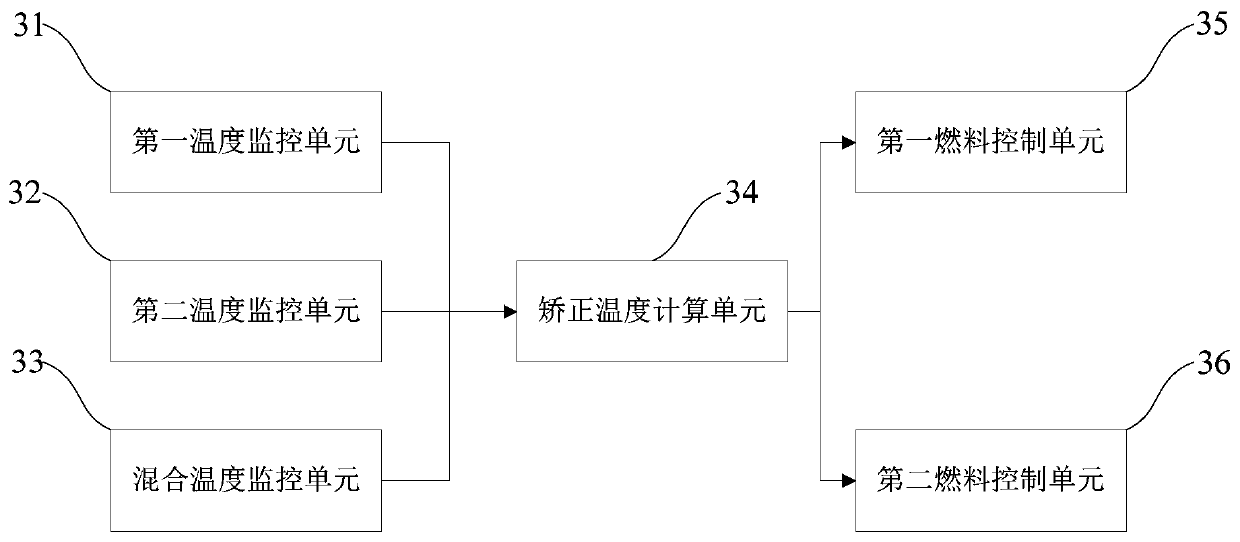

[0085] The first temperature monitoring unit 31 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com