Energy-saving desulfuration and denitrification dust collector for large boiler

A desulfurization, denitrification, desulfurization and dust removal technology, which is applied to combined devices, lighting and heating equipment, dispersed particle separation, etc. Health and other issues, to achieve the effect of benefiting workers' health, reducing smoke heat loss, and small resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

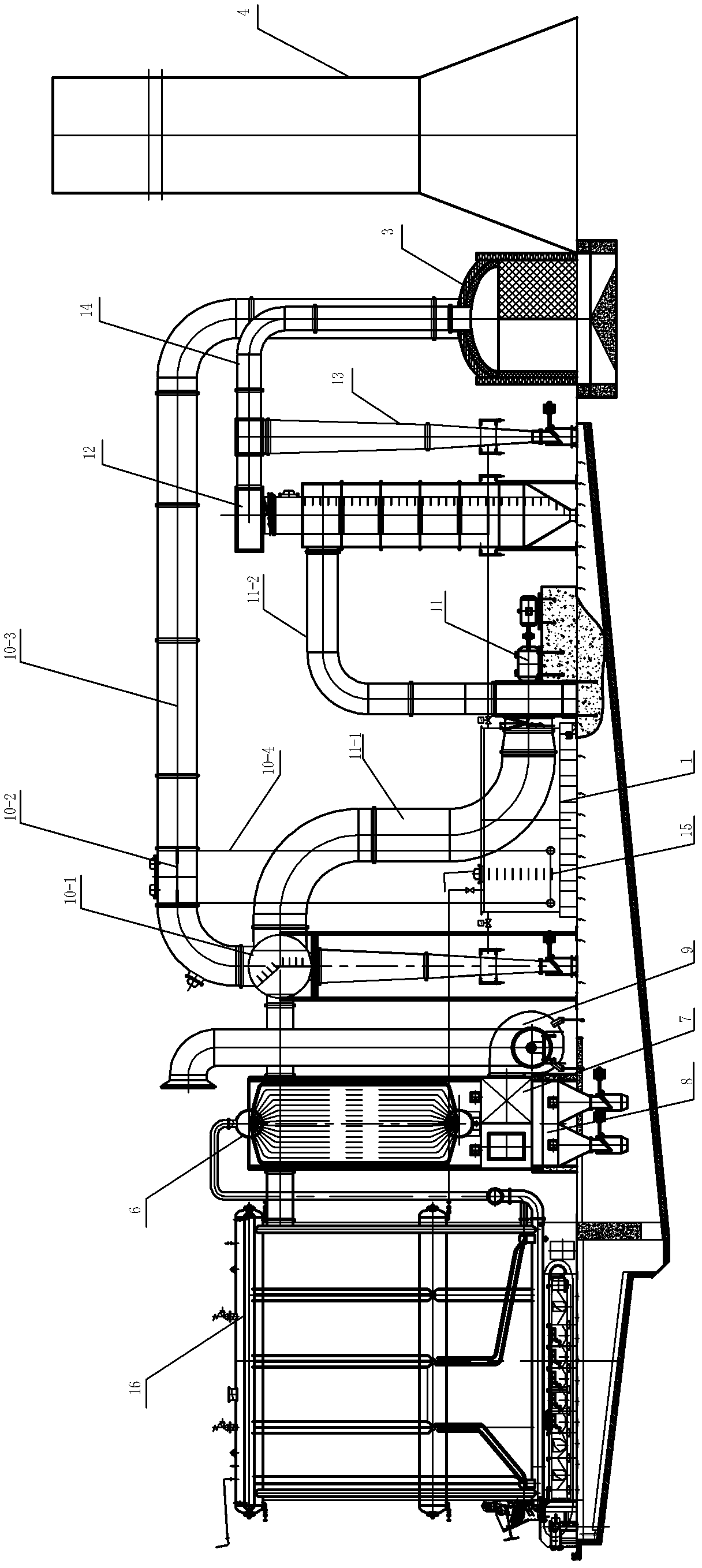

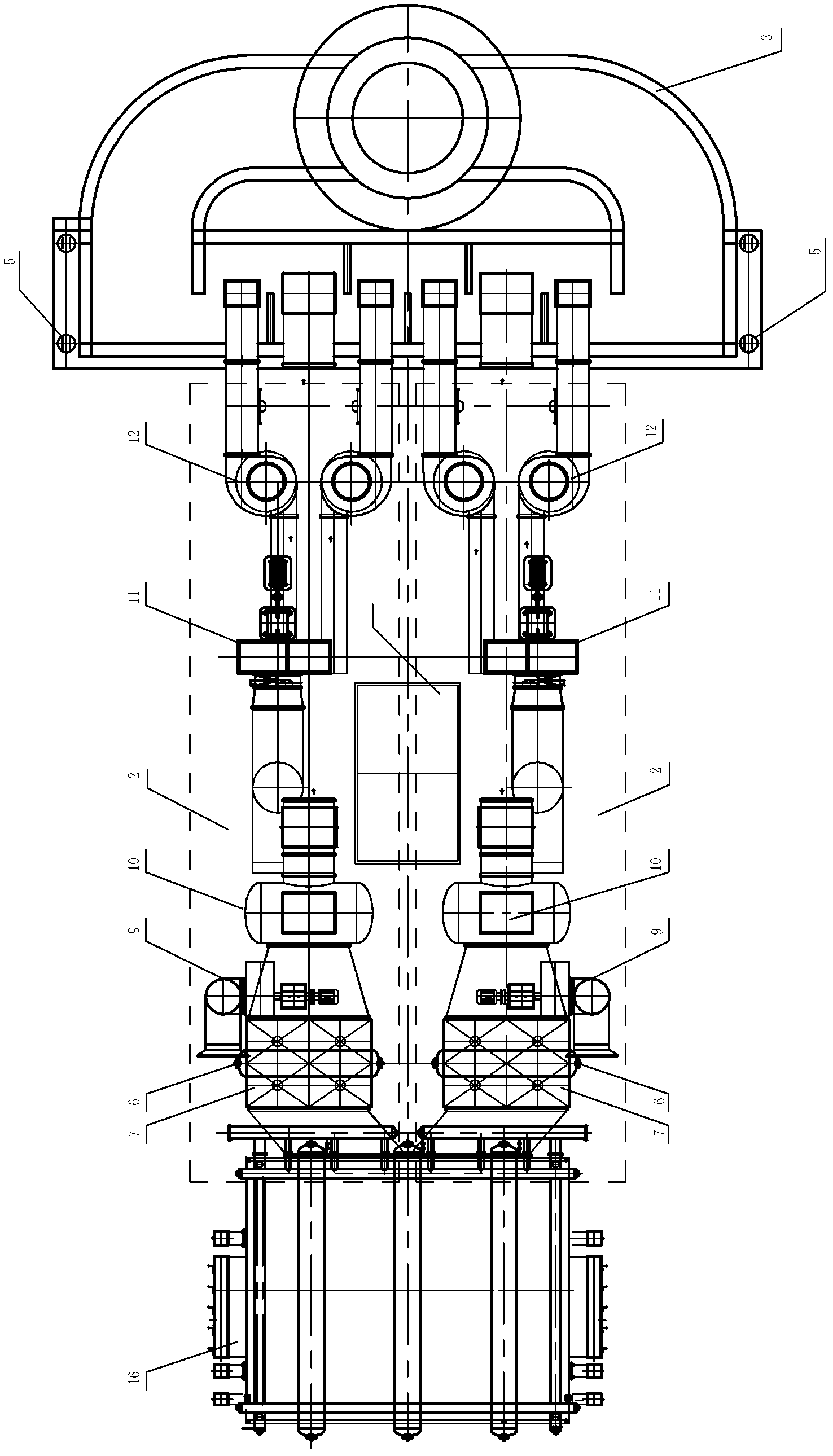

[0007] Specific implementation mode one: combine figure 1 and figure 2 Describe this embodiment, a large-scale boiler energy-saving desulfurization, denitrification and dust removal device described in this embodiment includes a water tank 1, two desulfurization and dust removal components 2, a chimney bridge 3, a chimney 4, a vertical drum vertical chain grate hot water boiler 16 and Four mud sewage pumps 5, vertical boiler chain grate hot water boiler 16 are connected to two desulfurization and dust removal components 2, two desulfurization and dust removal components 2 are connected to the chimney 4 through the chimney bridge 3, and four mud sewage pumps 5 are installed At the lower part of the chimney bridge 3, each desulfurization and dust removal assembly 2 includes a waste heat boiler 6, an air preheater 7, a first desulfurization and dust removal chamber 8, a blower 9, an explosion-proof bypass flue, a wet desulfurization and dust removal assembly 10, and an induced d...

specific Embodiment approach 2

[0008] Specific implementation mode two: combination figure 1 and figure 2 Describe this embodiment, the explosion-proof bypass flue and wet desulfurization dust collector assembly 10 of a large-scale boiler energy-saving desulfurization, denitrification and dust removal device described in this embodiment includes an explosion-proof bypass flue and wet desulfurization dust collector 10-1, a bypass Flue flue baffle 10-2, bypass flue 10-3 and smoke baffle zipper 10-4, explosion-proof bypass flue and wet desulfurization dust collector 10-1, explosion-proof bypass flue and wet desulfurization The dust collector 10-1 is connected with the chimney bridge 3 through the bypass flue 10-3, the bypass flue smoke baffle 10-2 is installed on the bypass flue 10-3, and the upper end of the smoke baffle zipper 10-4 It is connected with the bypass flue smoke baffle 10-2, and the water inlet end of the explosion-proof bypass flue and the wet desulfurization dust collector 10-1 is connected w...

specific Embodiment approach 3

[0009] Specific implementation mode three: combination figure 1 To illustrate this embodiment, a water tank escalator 15 is respectively provided on the outer wall and the inner wall of the water tank 1 of a large-scale boiler energy-saving desulfurization, denitrification and dust removal device in this embodiment. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com