Aluminum profile forming die and aluminum profile forming method

A molding die and molding method technology, applied in the field of aluminum profile manufacturing and processing, can solve problems such as changes in the metal properties of the aluminum profile, deformation of the internal cavity of the profile, and fracture of the aluminum profile, so as to save replacement costs, reduce extrusion efforts, and reduce machinery. The effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

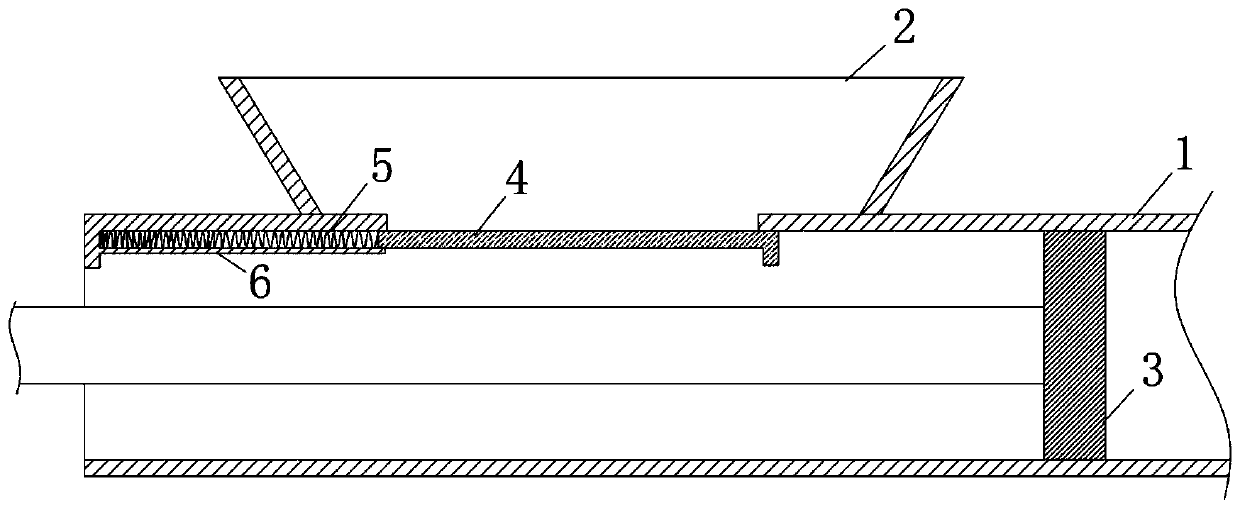

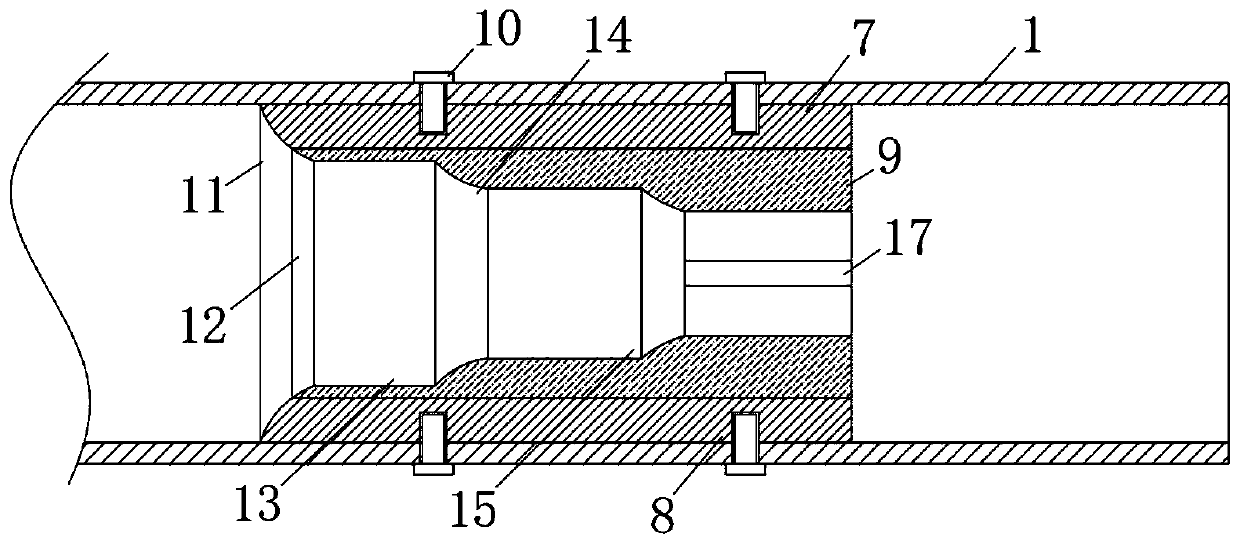

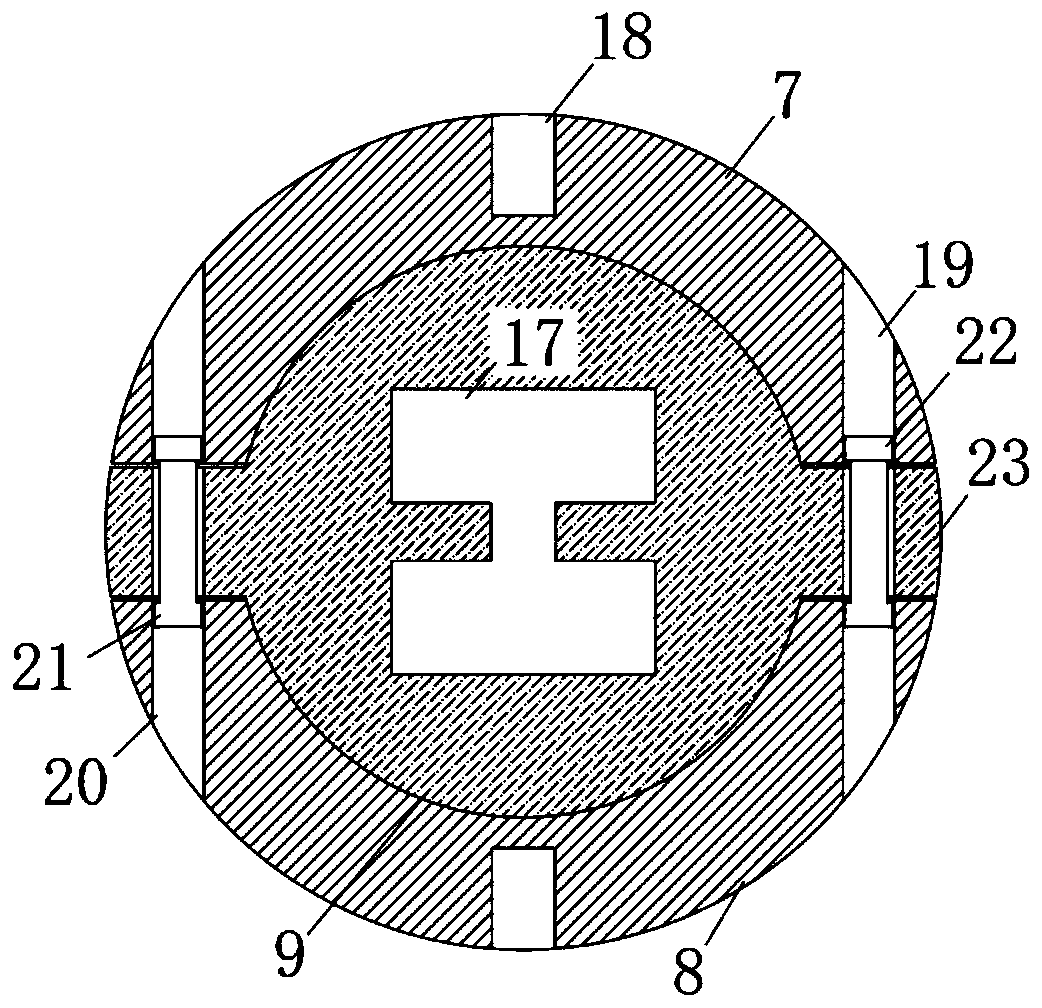

[0030] refer to Figure 1-4 , a forming die for aluminum profiles, comprising an extruded tube 1, an upper module 7 and a lower module 8 are installed in the extruded tube 1, a mold core 9 is fixed on the upper module 7 and the lower module 8, the upper module 7 and the lower module 8 are provided with a plurality of first installation holes 18, and the extruded tube 1 is provided with a plurality of second installation holes, and the plurality of second installation holes correspond to the plurality of first installation holes 18 one by one. A locking screw 10 is installed between the mounting hole 18 and the second mounting hole;

[0031] The upper module 7 is symmetrically provided with a plurality of first fixing holes 19, the lower module 8 is symmetrically provided with a second fixing hole 20, and the mold core 9 is symmetrically welded with two mounting strips 23, and each mounting strip 23 is provided with a A plurality of third fixing holes 24, a plurality of first ...

Embodiment 2

[0041] S1: First, weigh out the materials, 20 kg in total, and each metal is composed of each mass percentage: copper 0.4, manganese 0.15, magnesium 1.2, zinc 0.25, chromium 0.35, titanium 0.15, silicon 0.8, iron 0.7, and the balance of aluminum ingots. Put 20 kg of mixed material into the melting furnace for melting, and set the temperature to 740°C. After melting, remove the scum and gas through degassing and slag removal to prevent the slag and gas from affecting the alloy performance, and then pour the alloy liquid Enter the die-casting machine for die-casting, and the alloy liquid is die-cast into a cylindrical aluminum alloy.

[0042] S2: Heating the cylindrical aluminum alloy to the critical point of liquefaction of the aluminum alloy, at this time the cylindrical aluminum alloy softens, put the softened cylindrical aluminum alloy into the feed trough 2 on the extruded tube 1, and then start the extruder, The extrusion rod in the extrusion tube 1 drives the extrusion bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com