PVDF-HFP/PMMA/CMC composite film and preparation method thereof, and application of PVDF-HFP/PMMA/CMC composite film

A PVDF-HFP, composite membrane technology, applied in the field of PVDF-HFP/PMMA/CMC composite membrane and its preparation, can solve the problems of poor electrical conductivity of the blended membrane, improve the liquid retention rate, improve the cycle life, and improve the absorption rate. The effect of liquid rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

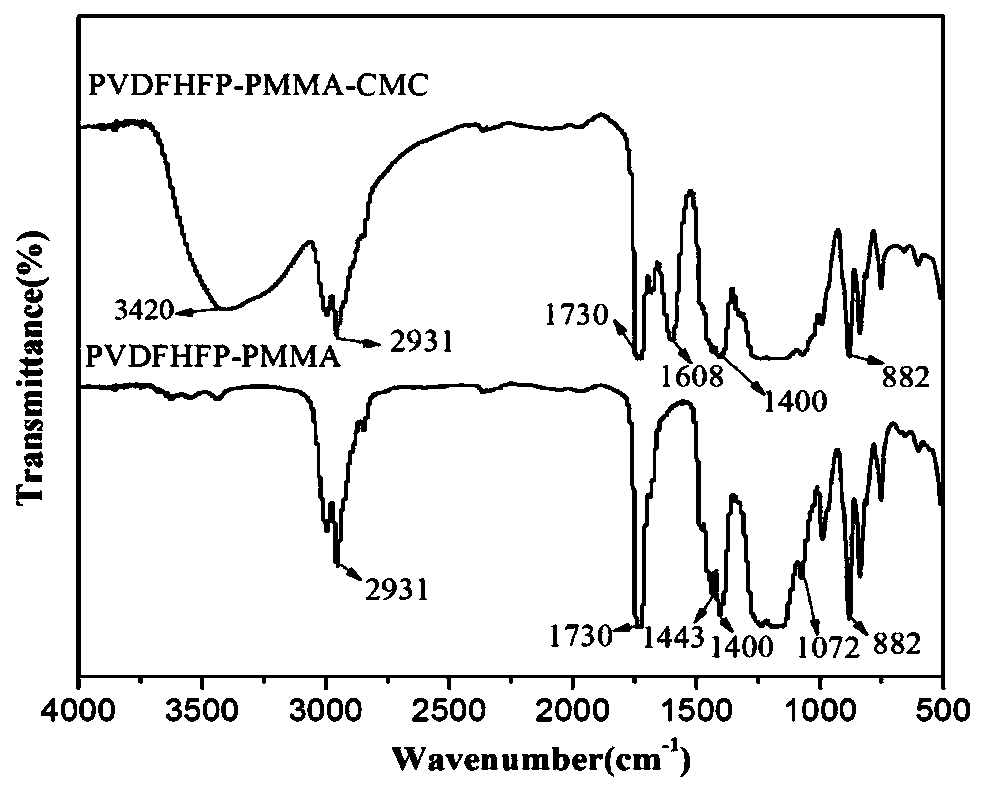

[0030] The present invention also provides a preparation method of the PVDF-HFP / PMMA / CMC composite membrane described in the above technical scheme, comprising the following steps:

[0031] (1) Provide PVDF-HFP / PMMA film;

[0032] (2) Apply a layer of CMC solution on the PVDF-HFP / PMMA film, and dry to obtain the PVDF-HFP / PMMA / CMC composite film.

[0033] The present invention provides PVDF-HFP / PMMA film earlier; The preparation method of described PVDF-HFP / PMMA film preferably comprises the following steps:

[0034] The PVDF-HFP, PMMA and solvent are mixed, and the PVDF-HFP / PMMA thin film is obtained through static defoaming, film formation and drying.

[0035] In the present invention, the solvent preferably includes acetone and DMF, and the volume ratio of the acetone and DMF is preferably 2.8-3.2:1, more preferably 3:1. The present invention does not specifically limit the amount of the solvent used, as long as the PVDF-HFP and PMMA can be fully mixed.

[0036] In the pr...

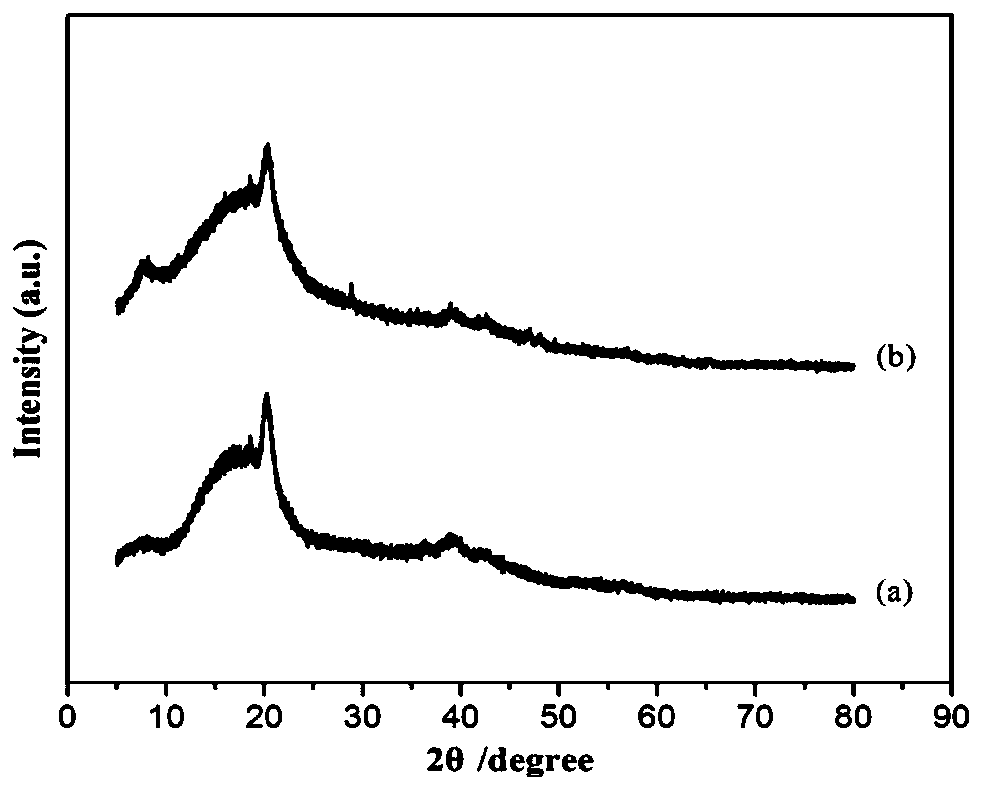

Embodiment 1

[0048] (1) Using acetone / DMF (volume ratio: 3:1) as solvent, add PVDF-HFP and PMMA particles (mass ratio: 1:1) into a single-necked flask, and stir at 60°C for 4 hours until the solution It is a transparent viscous liquid; stand to remove air bubbles, coat a film on a glass plate, and place it in a vacuum drying oven for 12 hours at 60°C to obtain a PVDF-HFP / PMMA film;

[0049] (2) Add 2g of carboxymethylcellulose (CMC), 50mL of water and 2.5mL of DMF into a single-necked flask, and stir at a constant temperature of 60°C for 4h until the solution becomes a transparent viscous liquid to obtain a CMC solution; stand to remove air bubbles , spread the PVDF-HFP / PMMA film on a glass plate, apply a layer of CMC solution on the PVDF-HFP / PMMA film with a spreader, and place it in a vacuum drying oven for 12 hours at 60°C for 50 seconds to obtain PVDF-HFP / PMMA / CMC composite membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com