Manufacturing method for silicon single crystal

A manufacturing method, silicon single crystal technology, applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problems of complicated setting of cultivation conditions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

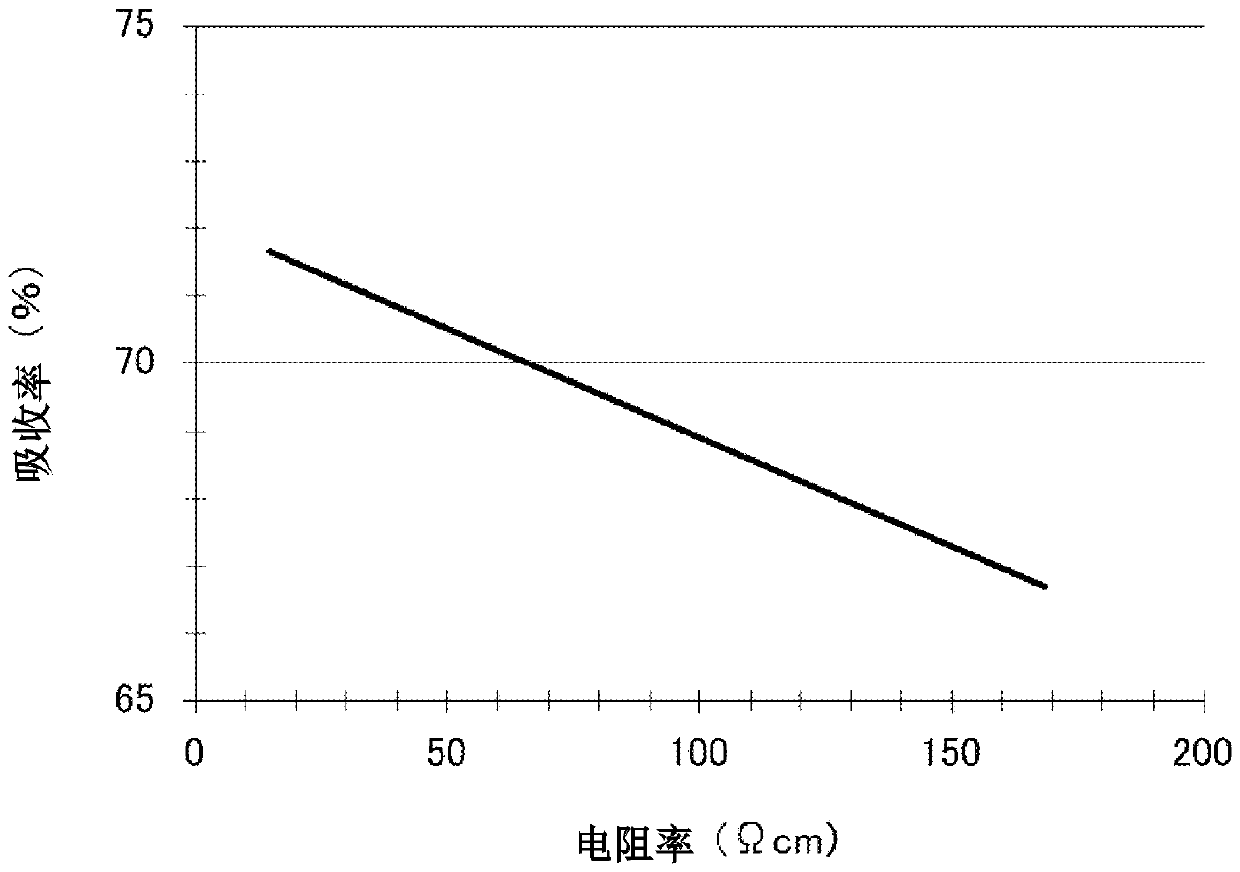

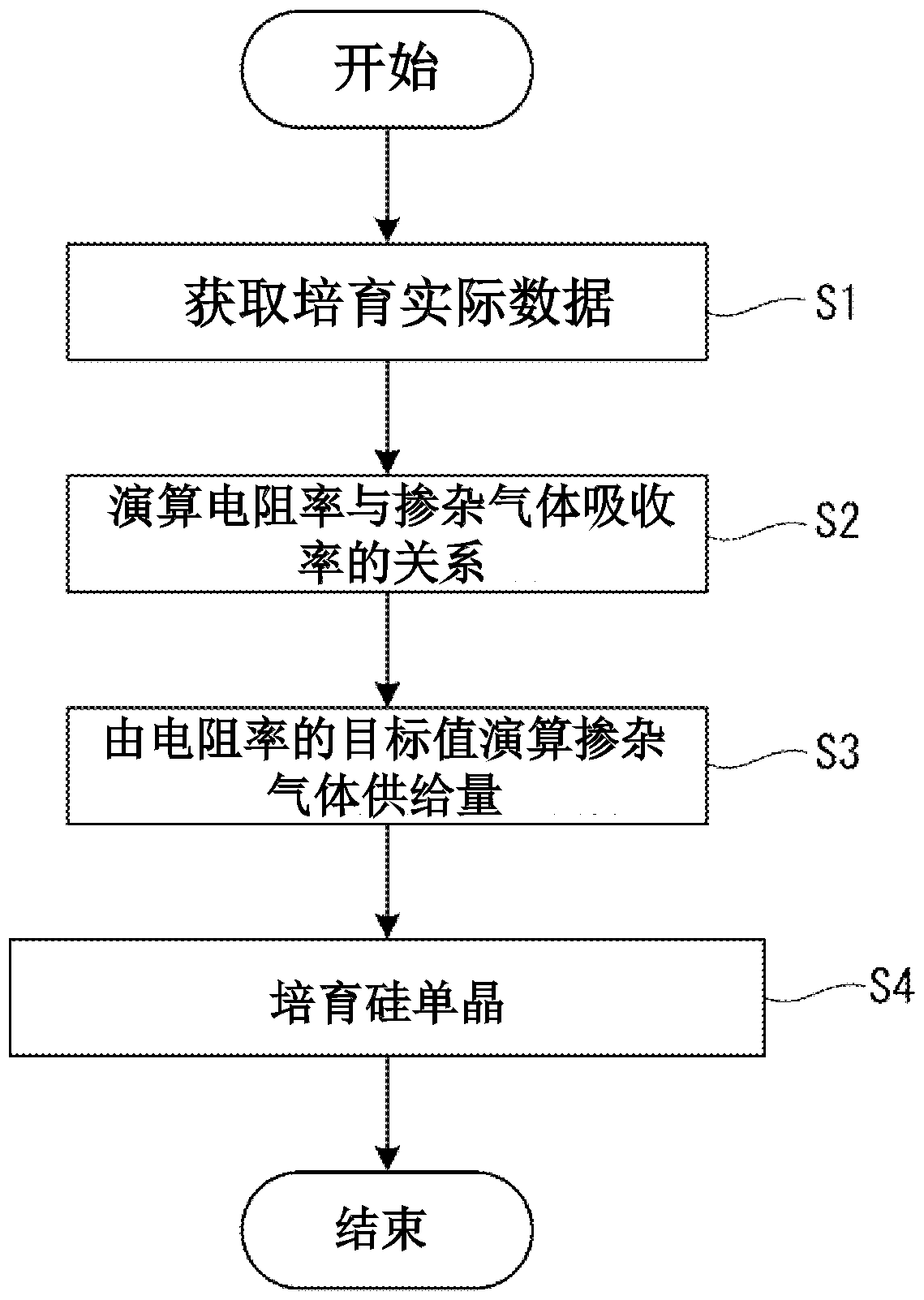

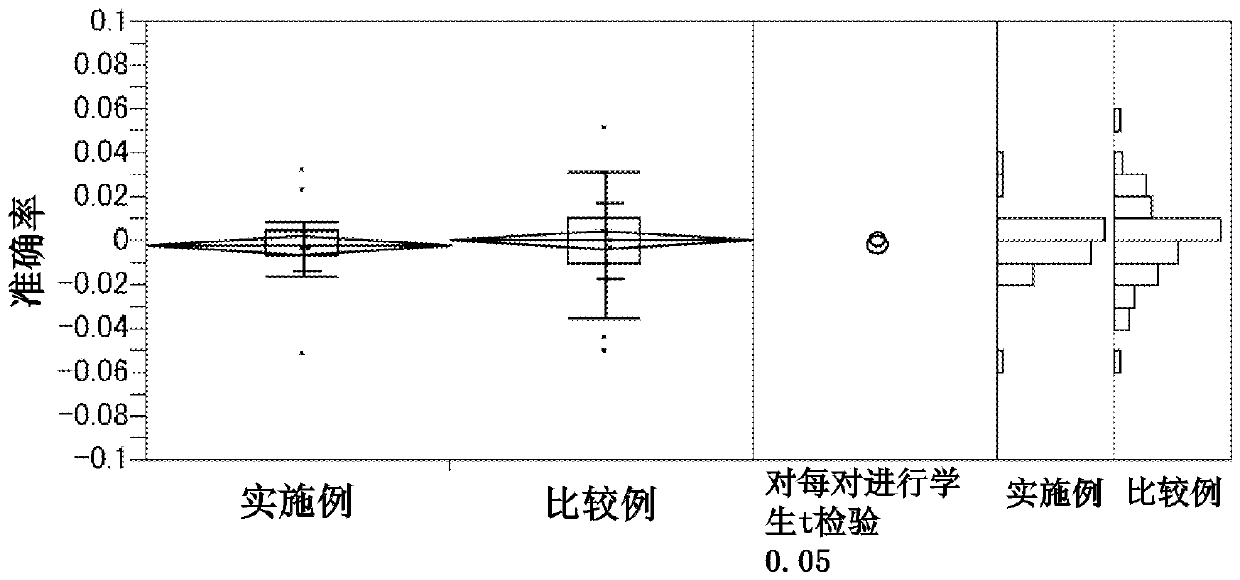

[0067] As described in the foregoing embodiment, the relationship between the measured electrical resistivity and the dopant gas absorptivity is calculated in the second step based on the actual cultivation data in the first step, and in the third step, the calculated dopant gas absorptivity , set the dopant gas flow rate in the next cultivation, and compare the above-mentioned scheme (example) with the situation that the dopant gas absorption rate of the previous time is kept constant (comparative example). It should be noted that the difference between the example and the comparative example is only the flow rate of the doping gas, and other processing conditions are the same.

[0068] A specific comparison method evaluates whether or not the actual value of the resistivity of the grown silicon single crystal 3 varies to some extent with respect to the target value of the resistivity as a variation in accuracy. That is, the accuracy rate is given by the following formula (3)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com