Voltage-controlled semiconductor construction, resistor, and method for manufacturing same

A technology for voltage control and resistors, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electric solid-state devices, etc., can solve the problems of large size of resistors and inability to adjust resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

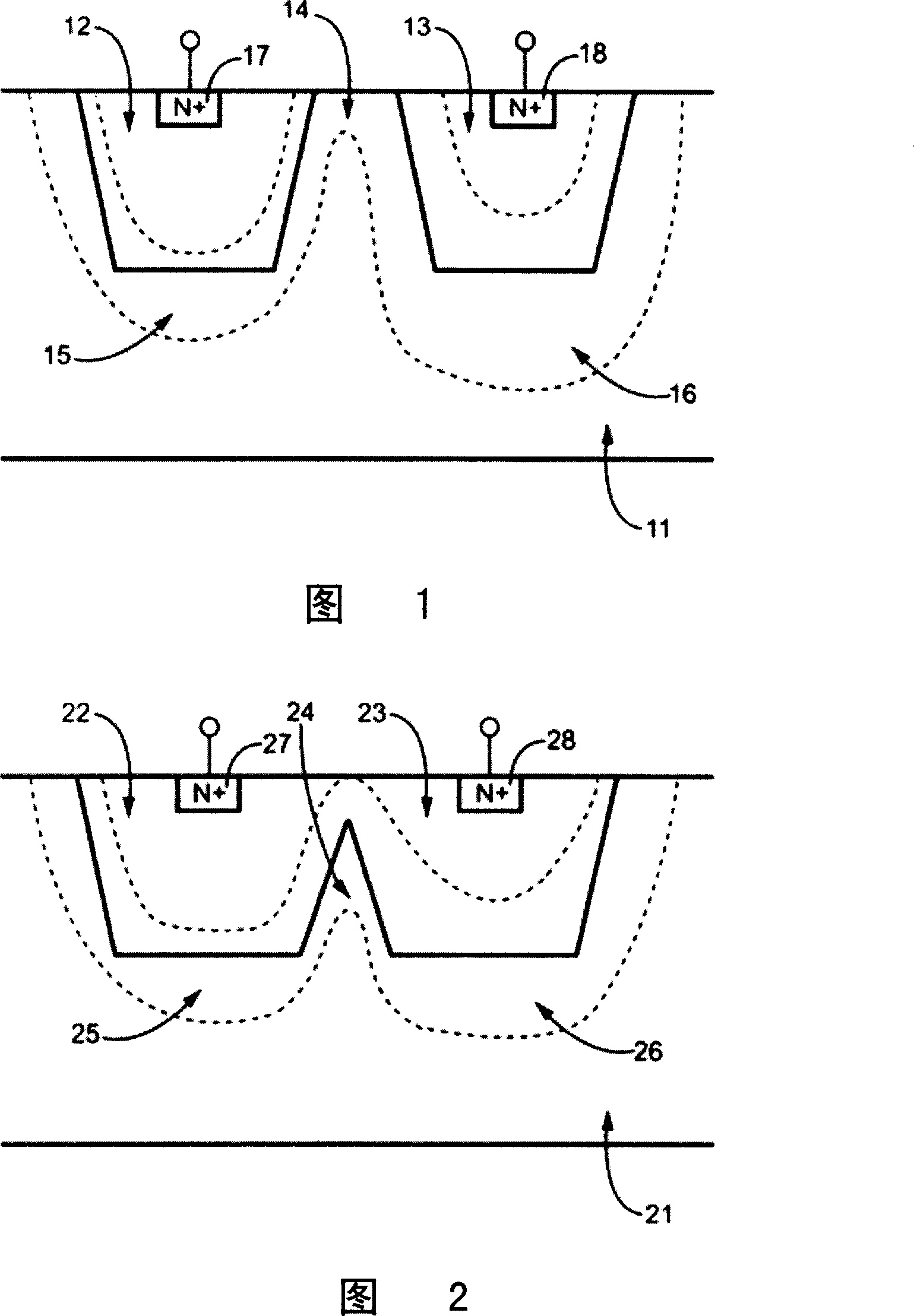

[0018] Figure 1 shows a first embodiment of the invention, which is a voltage controlled resistor. The resistor comprises a P substrate 11 and two deep N well regions 12 and 13 . Two N+ regions 17 and 18 are respectively formed in the two deep N well regions 12 and 13 as terminals of the resistor. The two deep N well regions 12 and 13 are formed on the P substrate 11 and are split. An equivalent resistor 14 is formed between the two deep N-well regions 12 and 13 . A depletion region 15 is formed between the deep N-well region 12 and the P-substrate 11 , the boundary of which is shown by two dashed lines. Similarly, a depletion region 16 is formed between the deep N well region 13 and the P substrate 11 , the boundary of which is shown by two dotted lines. The two depletion regions 15 and 16 are connected.

[0019] Through these N+ regions 17 and 18, a differential voltage is applied to the resistor, and between the P-type doped regions such as the P substrate 11 and the N-...

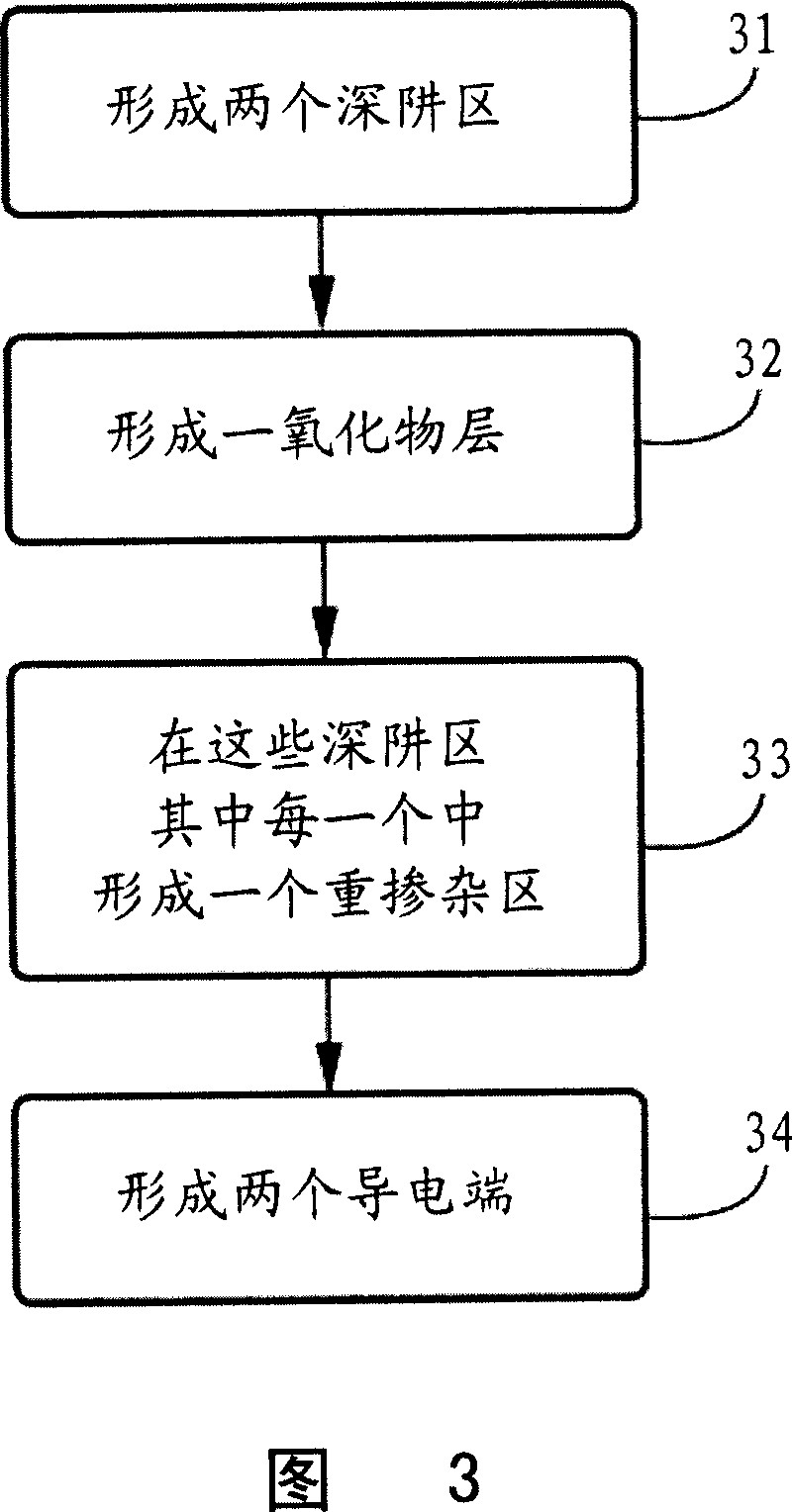

no. 3 Embodiment

[0026] In a third embodiment of the present invention, a semiconductor structure has an equivalent resistor area substantially equal to that of the first and second embodiments. The third specific embodiment includes a substrate and a deep well region formed in the substrate and has a gap, which means that the third specific embodiment is to apply the process of manufacturing the deep well region with a gap to realize the first The penetrating structure of a specific embodiment or the clamping structure of the second specific embodiment. The ion types of the substrate and the deep well region are complementary. Between the deep well region and the substrate, a depletion region is changed according to a voltage applied to the deep well region to control the resistivity of the semiconductor structure. When forming the penetrating structure and the pinching structure, a single photomask process is used to form the deep well region, which means that the process of forming the dee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com