Amorphous thermal spraying material resistant to high temperature corrosion and wear

A technology of thermal spraying and amorphous alloy, which is applied in the field of materials, can solve the problems of stress cracking, high cost, pulverization, etc., and achieve the effect of excellent high temperature corrosion resistance and wear resistance, low cost and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

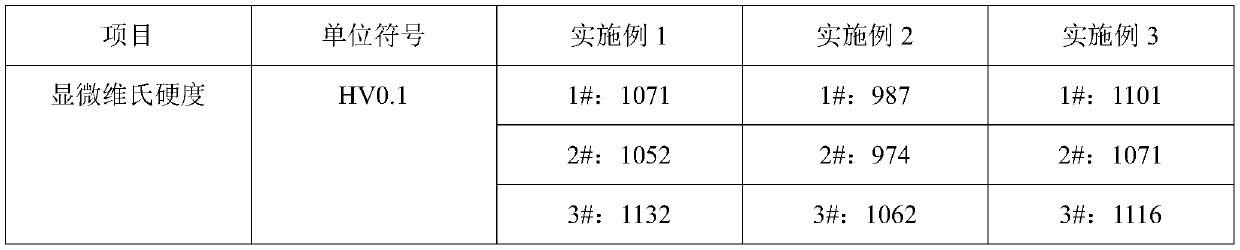

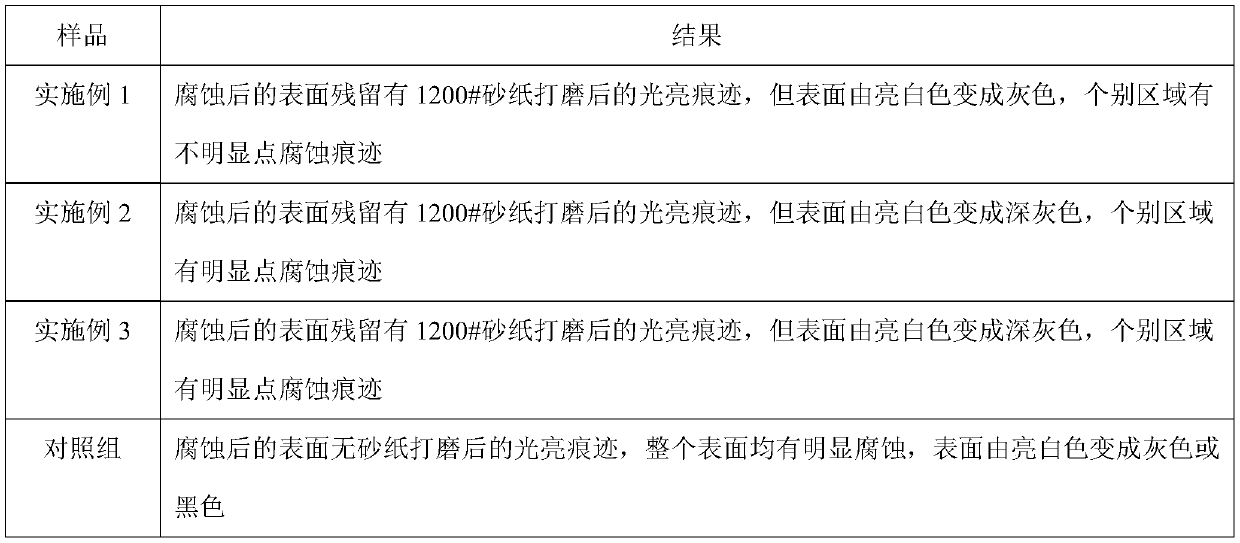

Embodiment 1

[0024] An amorphous alloy powder, prepared by conventional methods from the following raw materials in weight percentage: Mo: 22 parts, B: 8 parts, C: 10 parts, Ni: 2 parts, Cr: 32 parts, Si: 2 parts, Fe: 12 parts, Re: 0.03 parts, other impurity elements total ≤ 0.05 parts.

[0025] In this example, the conventional method for preparing amorphous alloy powder is the nitrogen atomization method (cooling rate is 500-1000°C / s).

[0026] The rare earth element Re can increase the elongation and area reduction of the deposited metal, and can significantly improve the sulfide corrosion resistance of the deposited metal. Among them, La, Ce, and Sc can improve the thermoplasticity of molybdenum-chromium-iron alloy. In this embodiment, Re is a combination of La and Ce.

[0027] Impurities in alloy powders are components that cannot be avoided during the preparation process and material selection process, including Mn, S, P, etc.

[0028] In this embodiment, a product comprising a hi...

Embodiment 2

[0030] An amorphous alloy powder, prepared by conventional methods from the following raw materials in weight percentage: Mo: 5 parts, B: 2 parts, C: 0.5 parts, Ni: 0.1 parts, Cr: 5 parts, Si: 0.1 parts, Fe: 0.3 parts, Re: 0.01 parts, other impurity elements total ≤ 0.05 parts. Wherein, Re is a combination of La and Sc.

[0031] In this embodiment, a product comprising a high-temperature, corrosion-resistant and wear-resistant coating is formed by spraying the above-mentioned amorphous alloy powder on the surface of the nickel-based alloy with a plasma spraying device. Among them, the nickel-based alloy is Inconel 625; the coating thickness is 400 μm. The surface bonding strength is 52.1MPa.

Embodiment 3

[0033] An amorphous alloy powder, prepared by conventional methods from the following raw materials in weight percentage: Mo: 30 parts, B: 18 parts, C: 25 parts, Ni: 3 parts, Cr: 50 parts, Si: 5 parts, Fe: 20 parts, Re: 0.05 parts, other impurity elements total ≤0.05 parts. Wherein, Re is Ce.

[0034] In this embodiment, a product comprising a high-temperature, corrosion-resistant and wear-resistant coating is formed by spraying the above-mentioned amorphous alloy powder on the surface of the nickel-based alloy with a laser cladding device. Among them, the nickel-based alloy is Inconel 625; the coating thickness is 700 μm. The surface bonding strength is 55.2MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com