Method for preparing homogeneous boron/nitrogen-doped red titanium dioxide

A titanium dioxide and boron doping technology is applied in the field of doping preparation of photocatalytic materials, which can solve the problems of inability to achieve strong absorption of visible light, and achieve the effects of improving the application potential of photocatalysis, low environmental pollution and high light absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

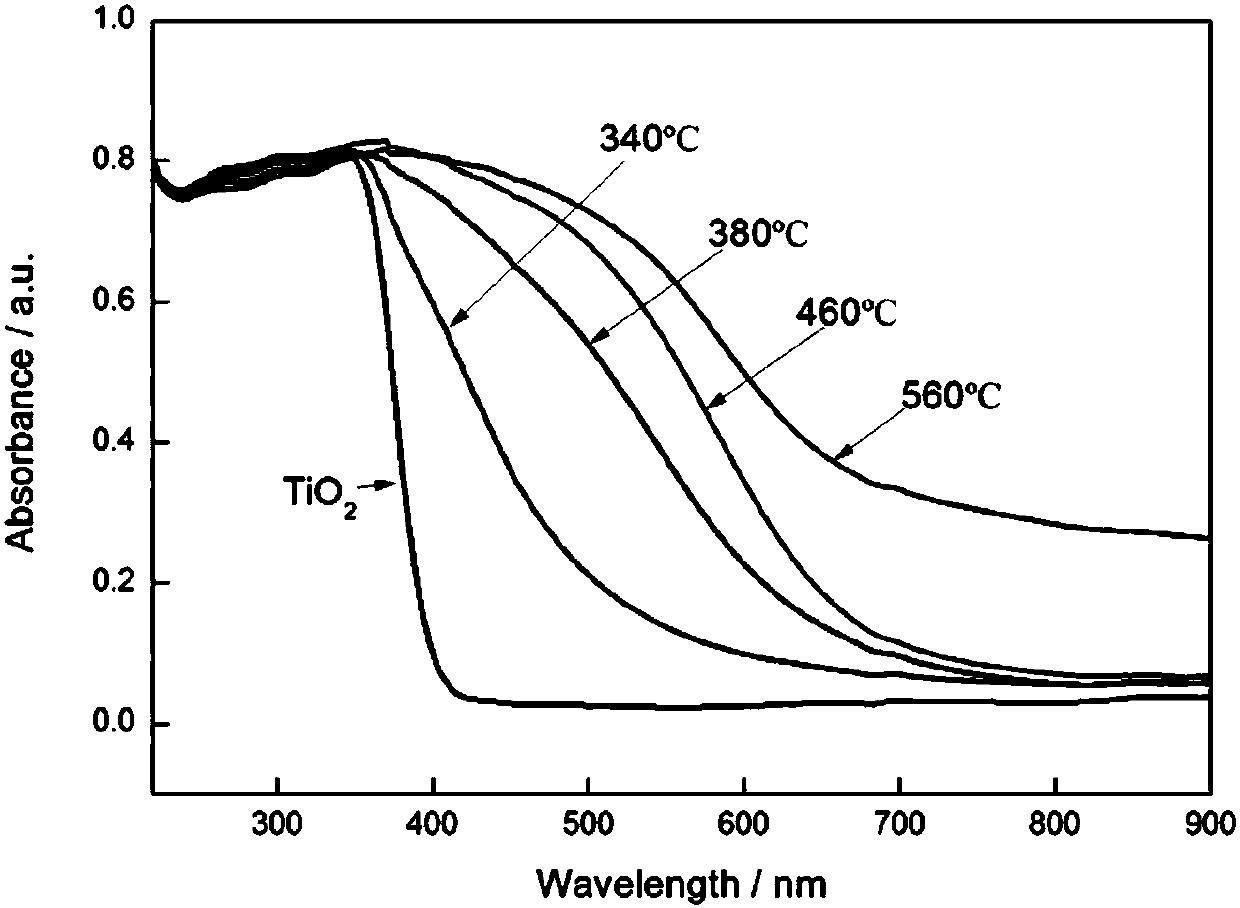

[0037] In this example, boron-doped anatase titanium dioxide microspheres are used as the starting material, and the absorption spectra of the samples prepared at different processing temperatures are studied.

[0038] Put the boron-doped anatase titanium dioxide microsphere sample and urea in a mass ratio of 3:1, place it in a quartz boat and cover it, firstly purge with argon gas at room temperature for 20 minutes, then keep the flow rate of argon gas constant, According to the program, the temperature is raised to a specific temperature of 340°C, 380°C, 460°C, and 560°C, followed by heat preservation for 2 hours.

[0039] Absorption spectrum testing equipment: UV-visible spectroscopy, JASCO-770, measured in diffuse reflectance mode. figure 1 The absorption spectra of the obtained samples treated at different temperatures are given. It can be seen from the figure that compared with the original titanium dioxide sample, the visible light absorption modification effect of the...

Embodiment 2

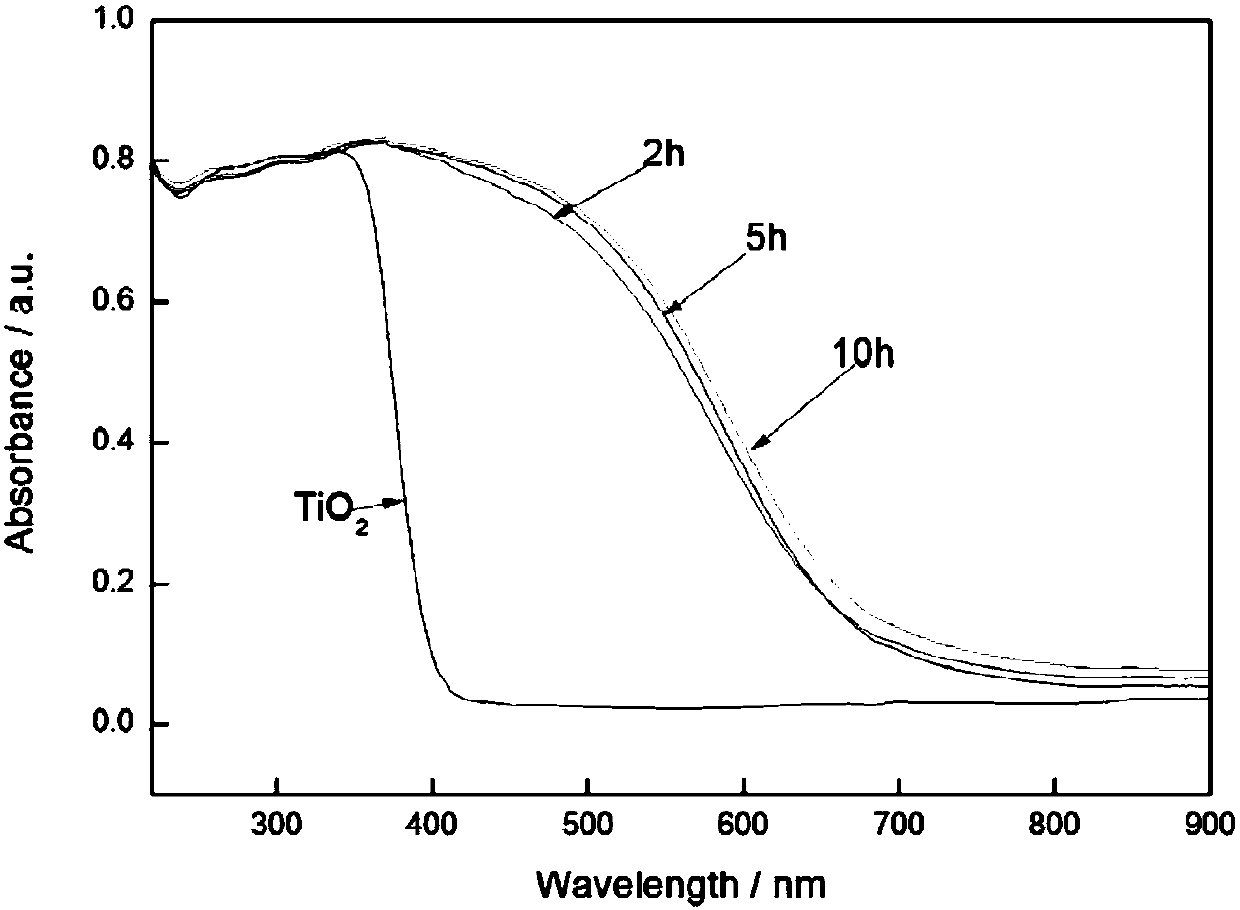

[0041] The difference from Example 1 is that in this example, boron-doped anatase titanium dioxide microspheres are used as the starting material, and the absorption spectra of the samples prepared at 460° C. for different time are studied.

[0042] Absorption spectrum test condition is the same as embodiment 1. figure 2 The absorption spectra of the samples obtained after the samples were treated for 2h, 5h, and 10h are given. It can be seen from the figure that the processing time has an effect on the visible light absorption ability of the doping improved material. Under this temperature condition, the visible light absorption performance of the sample obtained by incubating for 5h is the best.

Embodiment 3

[0044] The difference from Example 1 is that this example uses boron-doped anatase titanium dioxide microspheres as the starting material, and studies the absorption spectra of samples prepared under different urea dosages.

[0045] The absorption spectrum test conditions are the same as in Example 1, and the amount of boron-doped anatase titanium dioxide microspheres is 100 mg. image 3 The absorption spectra of samples obtained by using 200mg, 300mg, and 400mg urea as doped nitrogen sources are given respectively. It can be seen from the figure that under the same treatment temperature and time conditions, the more doped nitrogen source is used, the higher the concentration of local doped active nitrogen atoms will be, resulting in a more obvious red shift of the visible light absorption edge of the sample.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com