Spliced grouting sleeve and building prefabricated part

A technology of grouting sleeves and prefabricated components, which is applied to building components, building reinforcements, building structures, etc., which can solve problems such as unfavorable construction efficiency, inconvenient transportation and storage, safe construction, engineering accidents, etc., to avoid collision deformation and corrosion Pollution, ease of transportation and storage, safe construction, and reduction of operational risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

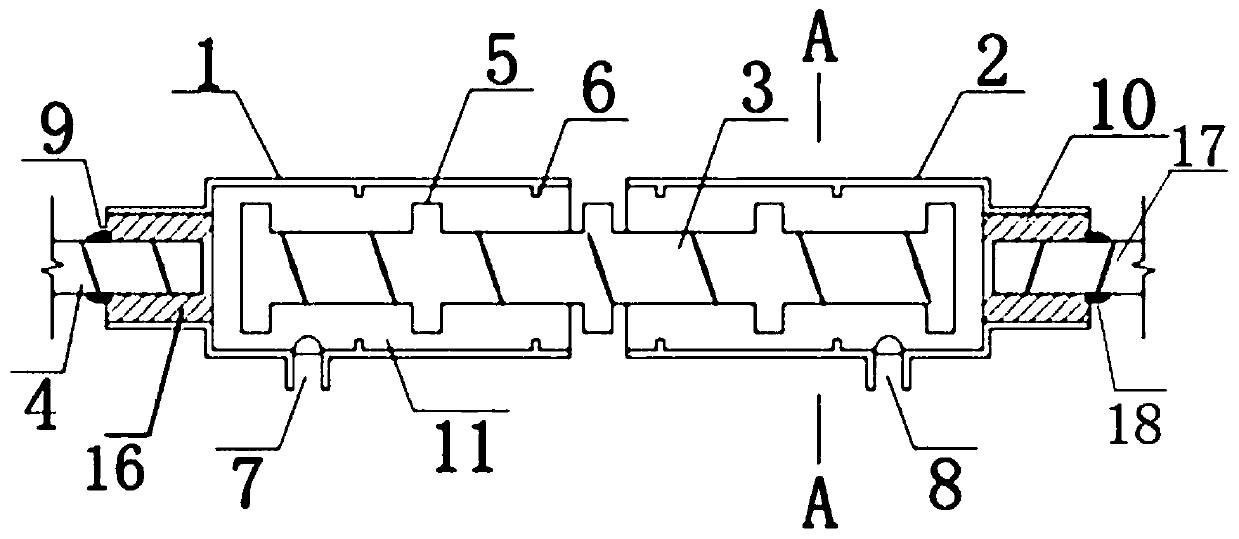

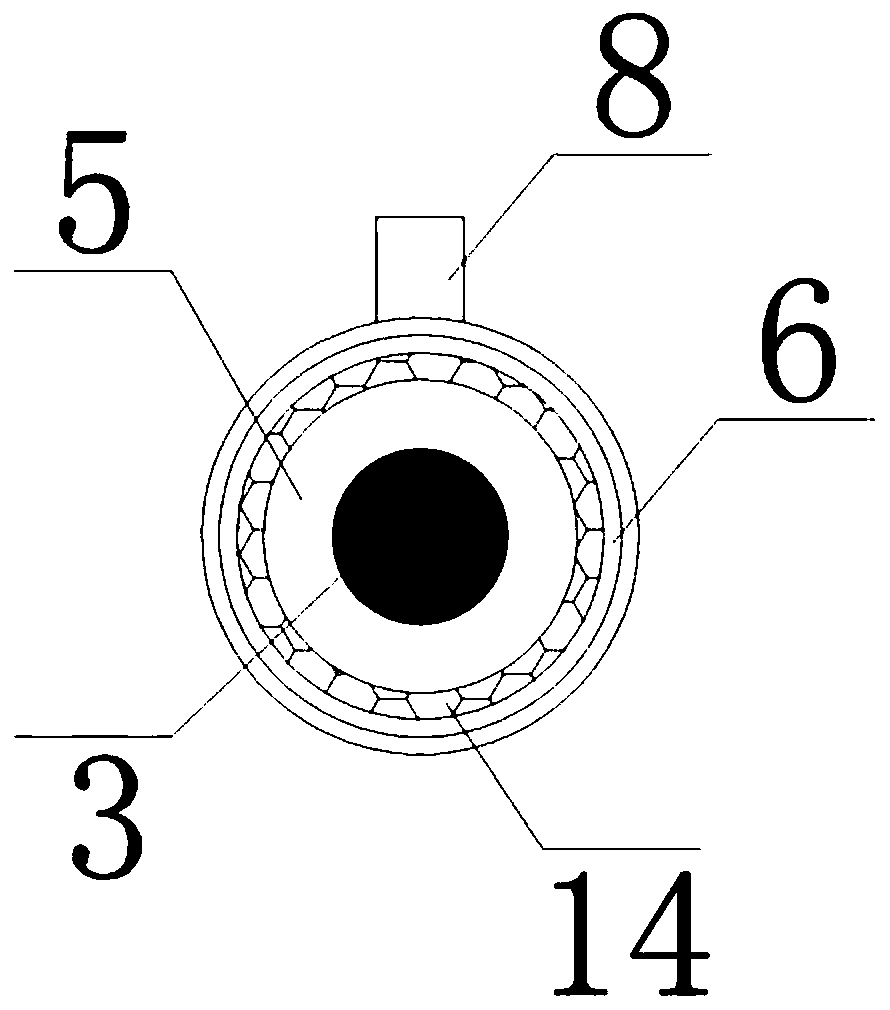

[0030] see figure 1 , in this embodiment, a spliced grouting sleeve, comprising: a first sleeve 2, a second sleeve 1, a connecting steel bar 3, and a grouting material 14; a section of the connecting steel bar 3 is accommodated in the first sleeve 2 , the other section of the connecting steel bar 3 is accommodated in the second sleeve 1, the connecting steel bar 3 is used to connect the first sleeve 2 and the second sleeve 1, the first sleeve 2 is close to the port of the second sleeve 1 and the second sleeve 1 The sleeve 1 is spliced close to the port of the first sleeve 2, and the grout 14 is filled in the sleeve cavity 11 formed by the first sleeve 2 and the second sleeve 1; figure 1 For the state of the grouting sleeves to be spliced, no grouting material 14 is filled in the sleeve cavities 11 of the first sleeve 2 and the second sleeve 1 .

[0031] The length and shape of the first sleeve 2 and the second sleeve 1 can be completely the same or different, as long as t...

Embodiment 2

[0048] Embodiment 2 provides a prefabricated building component, including a load-bearing body and a splicable grouting sleeve, one end of the splicable grouting sleeve is detachably connected to the pre-embedded steel bars of the load-bearing body, and the other end of the splicable grouting sleeve It is an open end, and the splicable grouting sleeve is provided with a grout port. The load-bearing body can be a shear wall or a prefabricated column.

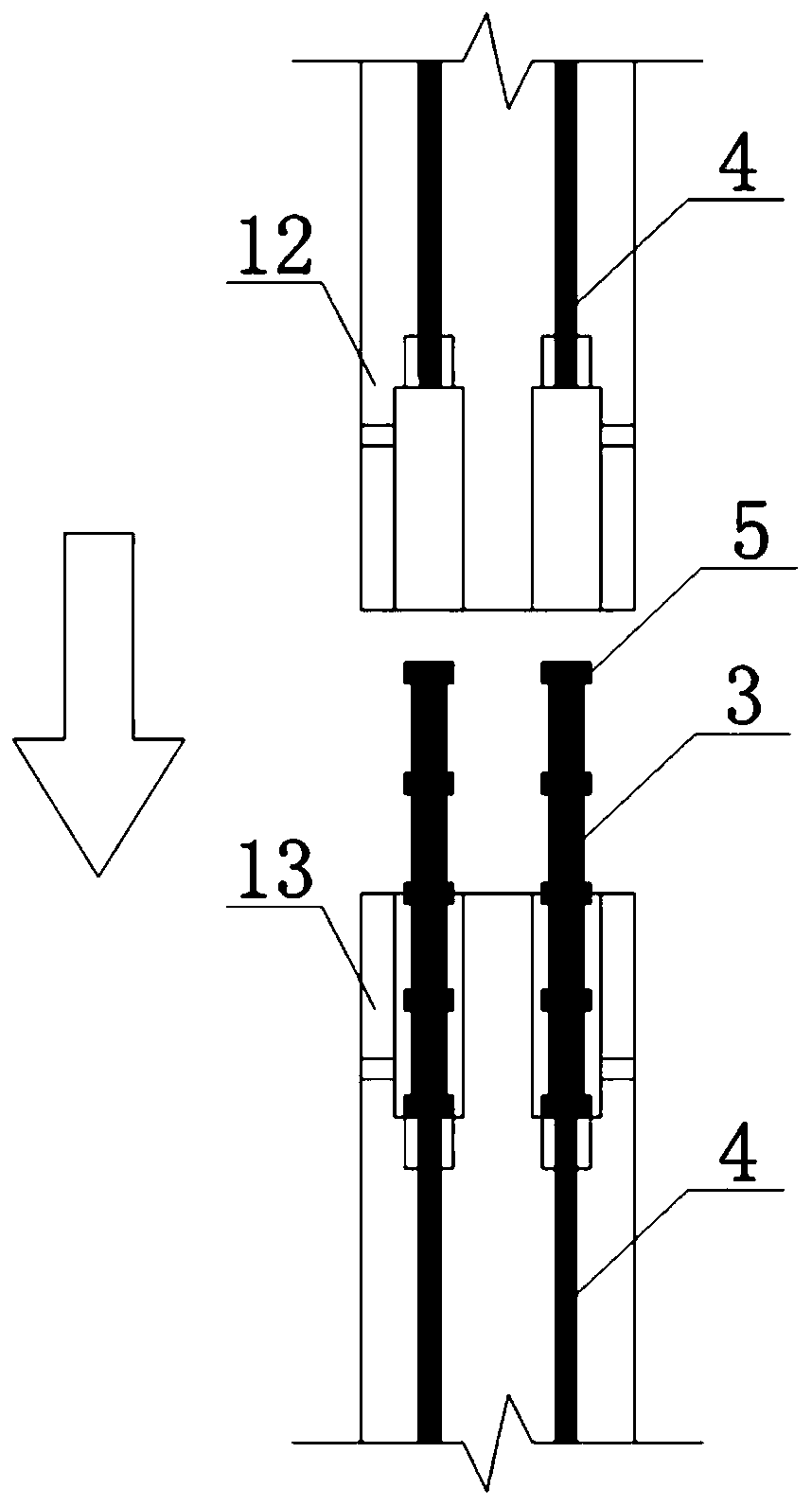

[0049] In construction engineering, shear walls mainly bear horizontal and vertical loads caused by wind loads or earthquakes to prevent structural shear damage, so shear walls are particularly important in earthquake-prone areas and other areas. The upper and lower prefabricated components can be shear walls, see image 3 and Figure 4 , the spliced grouting sleeve is used for prefabricated shear wall components, since the connecting steel bar 3 and the prefabricated shear wall can be transported and stored separately, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com