High-speed laser spraying device adopting coaxial powder feeding

A technology of laser spraying and coaxial powder feeding, applied in coating, metal material coating process and other directions, can solve the problems of high precision requirements of cladding head, limited powder acceleration distance, insufficient powder acceleration, etc. The effect of high utilization rate, high coating deposition efficiency and less powder splash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

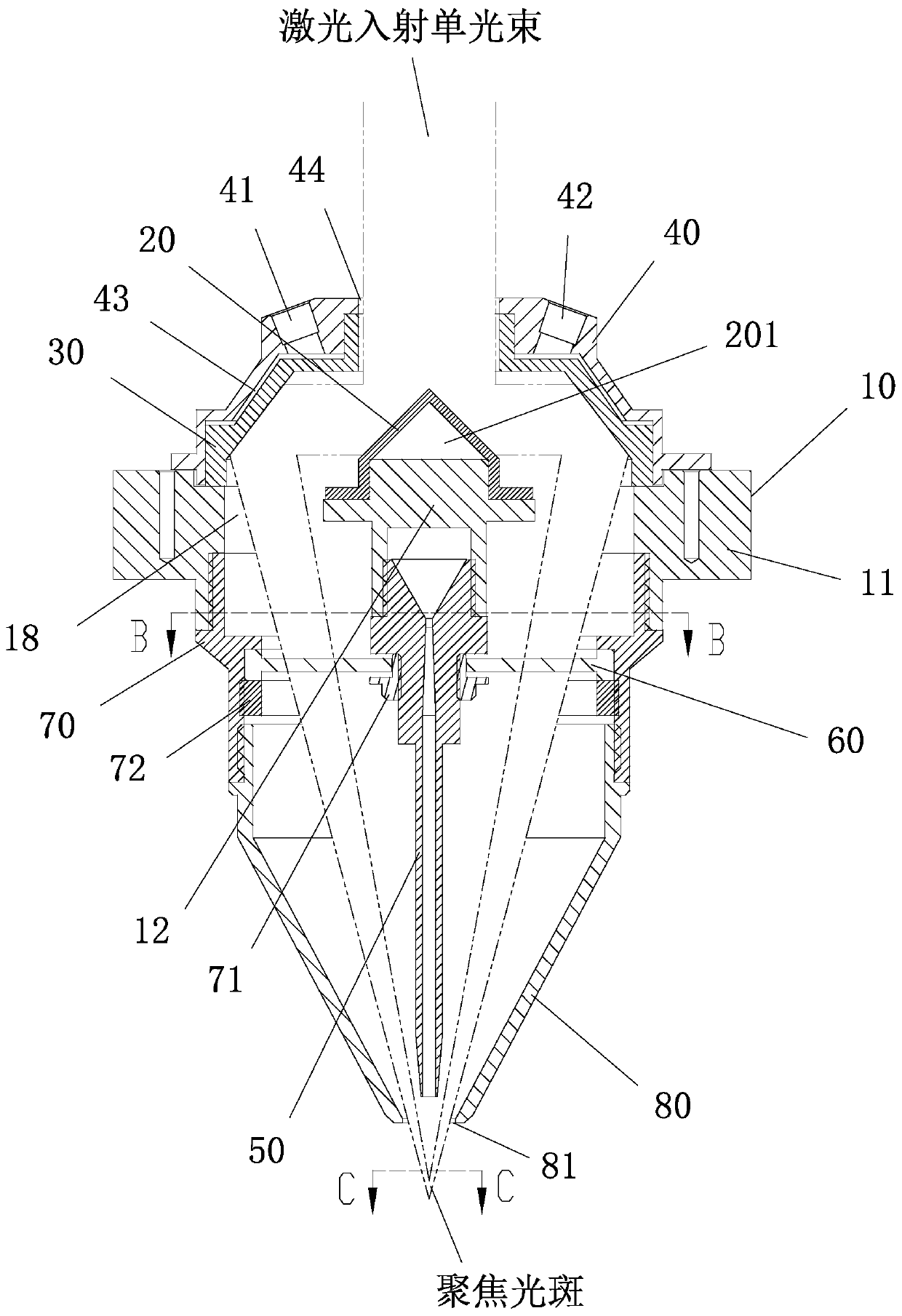

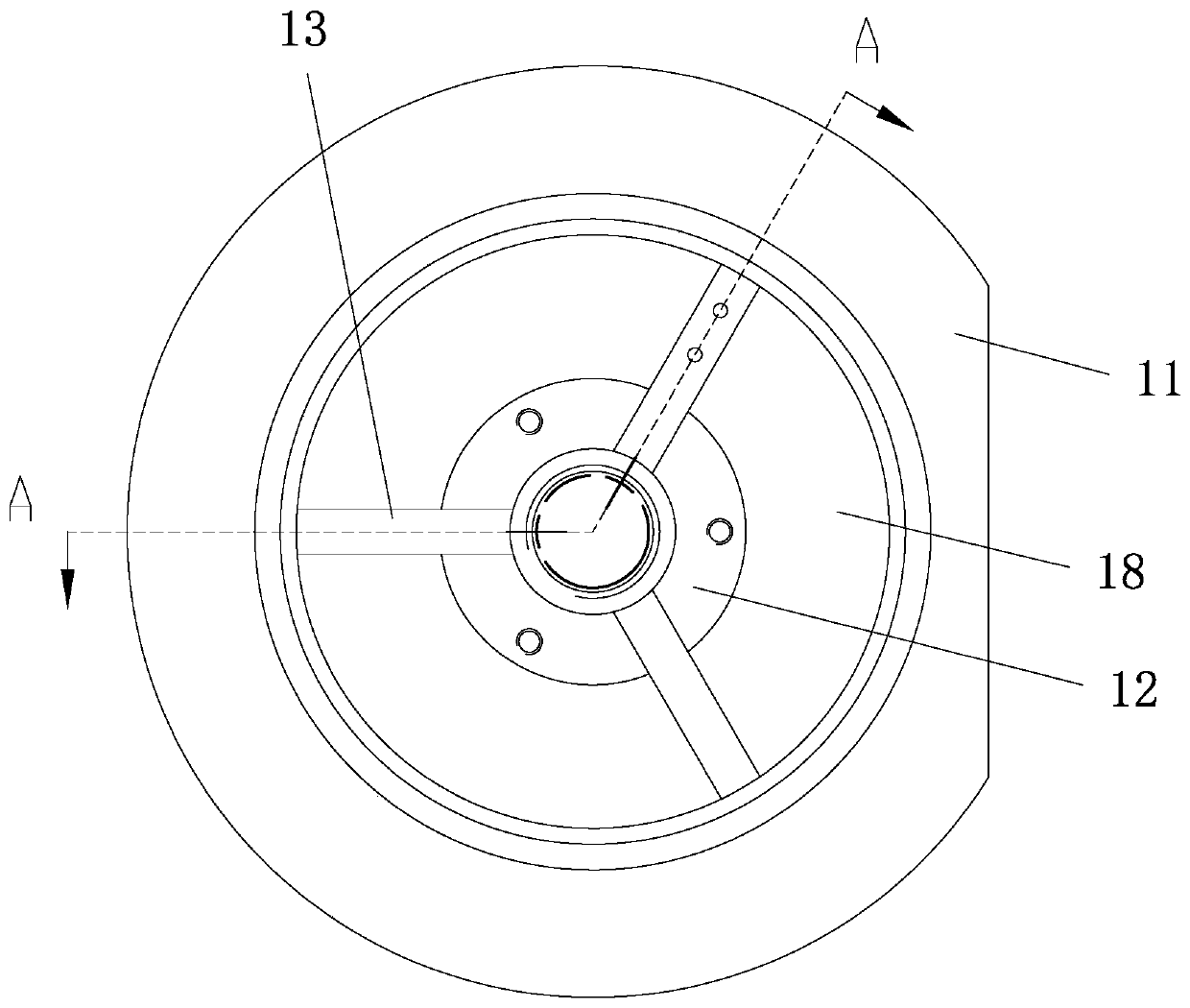

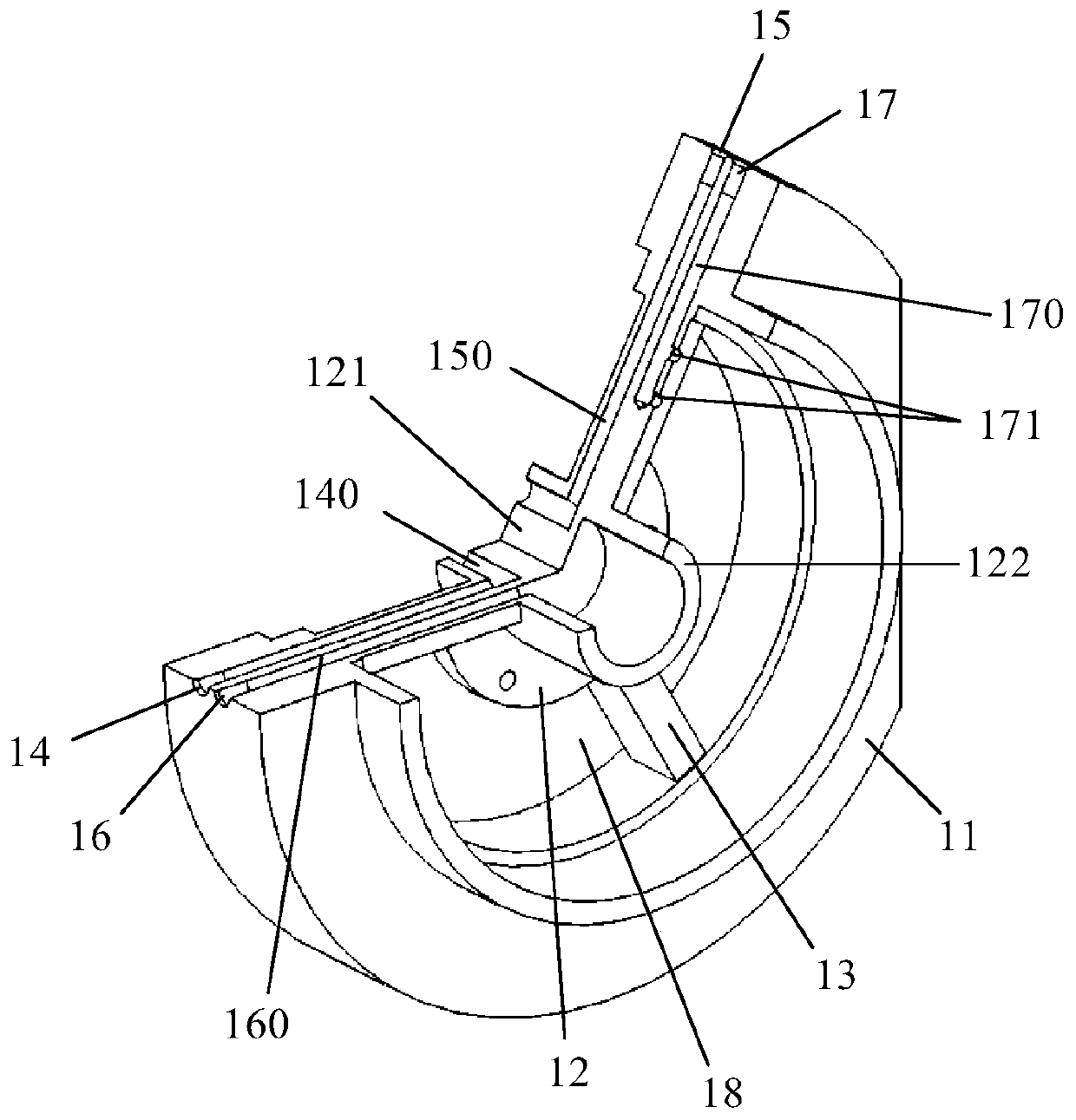

[0019] Such as Figure 1 to Figure 7 As shown, the coaxial powder-feeding high-speed laser spraying device of the present invention includes a support seat 10, wherein: the support seat 10 includes a ring-shaped support outer seat 11 (according to installation requirements, a certain position on the circumference of the support outer seat 11 can be made plane, such as figure 2 ) and a support inner seat 12 with a circular cross section, there is a gap 18 between the support outer seat 11 and the support inner seat 12, and the support outer seat 11 and the support inner seat 12 are connected by some support ribs 13; the top of the support inner seat 12 The spectroscopic reflector 20 is installed to support the bottom of the inner seat 12 to install the shrinking and expanding nozzle 50, and the top of the support outer seat 11 is to install the focusing reflector 30. The spectroscopic reflector 20 in the regular pyramid structure is located in the focusing reflector 30, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com