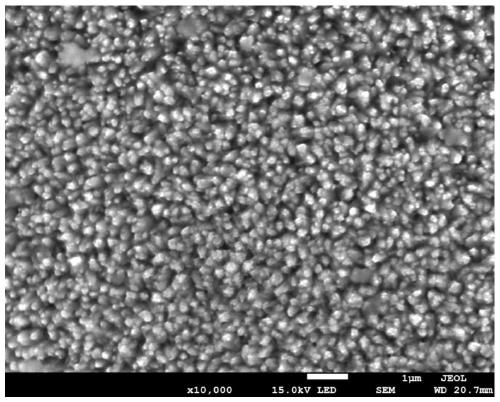

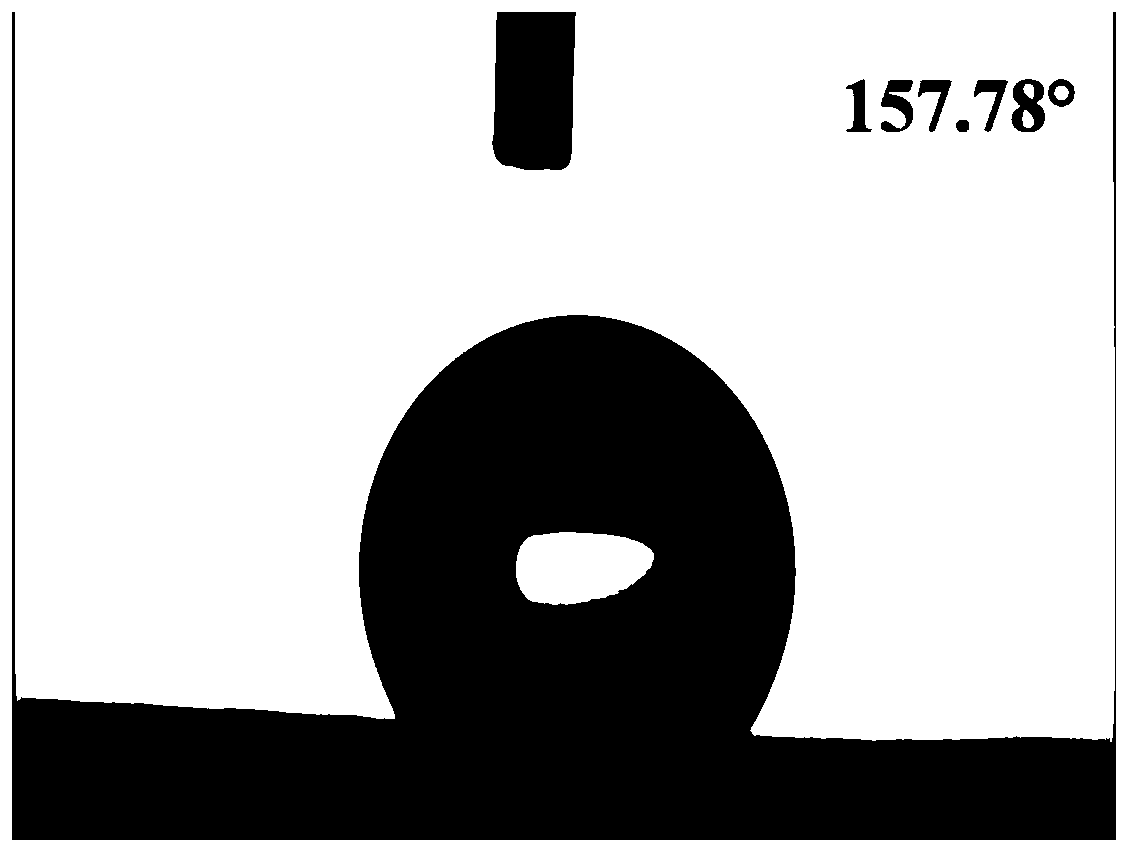

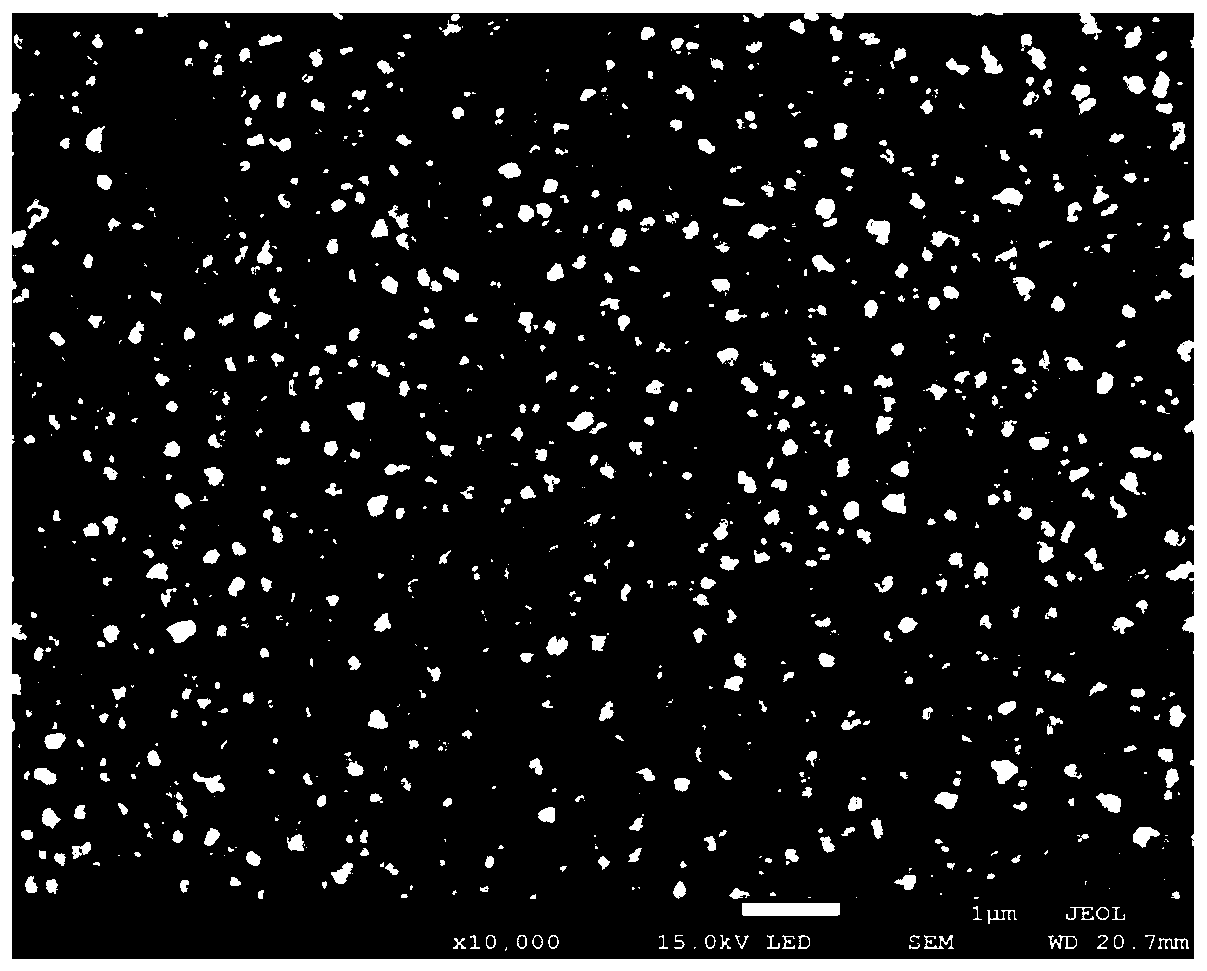

Method for preparing super-hydrophobic nano Ni3S2 coating on surface of nickel mesh

A super-hydrophobic, nickel mesh technology, applied in the direction of metal material coating process, etc., can solve the problems of strong dependence on production equipment, long production cycle, limiting the popularization and application of solvothermal reaction method, etc., to increase the popularization and application, good protection Effects with low dependence on action,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0024] (1) Cut a nickel mesh (purity ≥ 99.5%) with an opening size of 75 μm × 75 μm into a sample size of 25 mm × 25 mm, soak it in 100 mL of hydrochloric acid solution with a concentration of 0.5 mol / L for 10 min to remove surface oxidized substances, After taking it out, rinse it with deionized water and dry it quickly; then ultrasonically clean the sample in 100mL deionized water and 100mL absolute ethanol for 10min to remove surface impurities and oil, and dry it for later use;

[0025] (2) 0.025mol sodium hydroxide and 0.013mol ammonium persulfate are dissolved in a beaker with 100mL deionized water, fully stirred to make the solution mix uniformly; the nickel mesh processed through step (1) is soaked in the solution, Then heat in a water bath at 50°C for 10 minutes, take out the sample, rinse it with deionized water, and dry it quickly;

[0026] (3) Dissolve 0.002mol of sodium sulfate nonahydrate and 0.014mol of ammonium fluoride in 100mL of deionized water, and after mi...

specific Embodiment 2

[0030] (1) Cut the nickel mesh into a sample with a size of 25mm×25mm, soak it in 0.5mol / L hydrochloric acid solution for 10min to remove surface oxidized substances, rinse it with deionized water after taking it out, and dry it quickly; then put the sample in the Ultrasonic cleaning in deionized water and absolute ethanol for 10 minutes to remove impurities and oil on the surface, and dry for later use;

[0031] (2) 0.03mol sodium hydroxide and 0.02mol ammonium persulfate are dissolved in a beaker with 100mL deionized water, fully stirred to make the solution mix uniformly; the nickel mesh processed through step (1) is soaked in the solution, Then heat in a water bath at 60°C for 20 minutes, take out the sample, rinse it with deionized water, and dry it quickly;

[0032] (3) Dissolve 0.001mol sodium sulfate nonahydrate and 0.010mol ammonium fluoride in an appropriate amount of deionized water, and after mixing evenly, heat the solution in a water bath to 70°C, and soak the sa...

specific Embodiment 3

[0036] (1) Cut the nickel mesh into a sample with a size of 25mm×25mm, soak it in 1mol / L hydrochloric acid solution for 10min to remove surface oxidized substances, rinse it with deionized water after taking it out, and dry it quickly; Ultrasonic cleaning in ionized water and absolute ethanol for 10 minutes to remove impurities and oil on the surface, and dry for later use;

[0037] (2) 0.04mol sodium hydroxide and 0.025mol ammonium persulfate are dissolved in a beaker with 100mL deionized water, fully stirred to make the solution mix uniformly; the nickel mesh processed through step (1) is soaked in the solution, Then heat in a water bath at 40°C for 30 minutes, take out the sample, rinse it with deionized water, and dry it quickly;

[0038] (3) Dissolve 0.003mol of sodium sulfate nonahydrate and 0.020mol of ammonium fluoride in an appropriate amount of deionized water, and after mixing evenly, heat the solution in a water bath to 85°C, and soak the sample obtained in step (2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roll angle | aaaaa | aaaaa |

| Roll angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com