Taste-masked drug granules and preparation method thereof

A technology of drugs and granules, applied in the field of pharmaceutical preparations, can solve the problems of difficulty in control, limited application, large amount of plasticizer, etc., and achieves the effects of short time consumption, rapid in vitro release, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

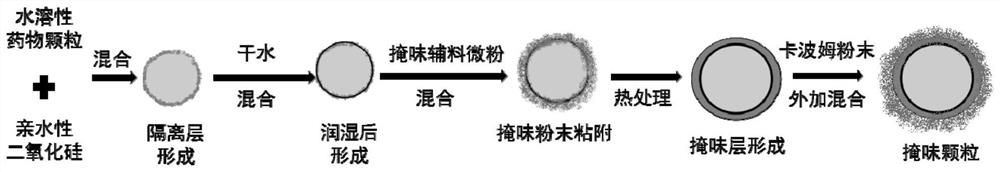

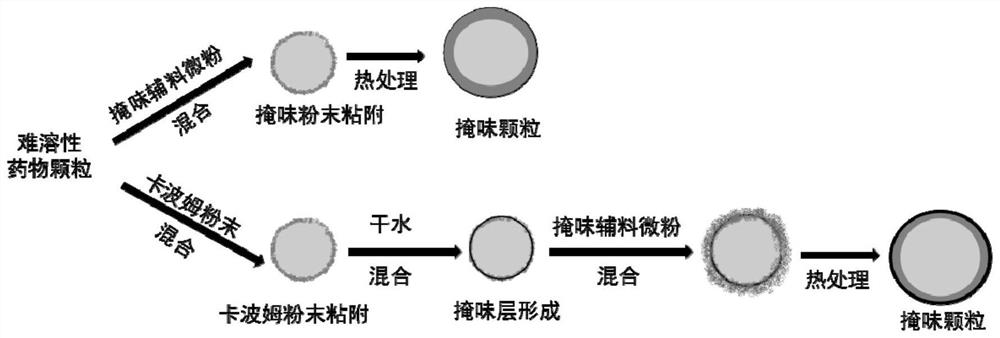

[0031] Specifically, the preparation method of the taste-masked drug particles of the present invention comprises the following steps:

[0032] 1. Preparation of dry water: Add a certain amount of hydrophobic silicon dioxide to the container, add the inner core aqueous phase solution into the powder bed drop by drop, stir at low speed for 5-20 minutes, and then stir at high speed for 1-10 minutes. Wherein, the inner core water phase: hydrophobic silica = 9-17:1 (w / w), and the prepared dry water particle size is 20 μm-300 μm. The obtained dry water powder is passed through a 60-100 mesh sieve for later use.

[0033] 2. Preparation of drug granules: Weigh a certain amount of drug powder, add 0-2 times the mass of filler and mix evenly, add an appropriate amount of binder to prepare soft material granules, dry at 40-60°C and sieve to 100 mesh - 60 mesh particles.

[0034] 3. Isolation layer mixing powder coating: transfer the bitter drug granules to a mixer or coating pan, add th...

example 1

[0041] Example 1: Preparation of cetirizine hydrochloride taste-masking granules

[0042] 1. Preparation of dry water: add an appropriate amount of hydrophobic silica to the container, add 2.5wt.% sodium alginate aqueous solution dropwise into the powder bed, stir at a low speed of 1000 rpm for 10 min, then increase the speed to 1600 rpm for stirring Serve in 5 minutes. Among them, the inner core water phase: hydrophobic silica = 12: 1 (w / w), and the prepared dry water particle size is 20 μm - 300 μm. The obtained dry water powder is passed through a 60-mesh sieve for subsequent use.

[0043] 2. Preparation of drug granules: Weigh cetirizine hydrochloride powder, use 5wt.% PVP K30 aqueous solution as a binder, add an appropriate amount of binder to make soft materials, and use a 60-mesh sieve for granulation. The wet granules were dried in an oven at 60°C for 30 min and then taken out, and the drug granules with a particle size of 60-100 mesh were screened for use.

[0044]...

example 2

[0052] Example 2: Preparation of ibuprofen taste-masked granules

[0053] 1. Preparation of dry water: Add hydrophobic silicon dioxide to the container, add 5% calcium chloride aqueous solution dropwise into the powder bed, stir at 1300 rpm for 20 min at a low speed, then increase the speed to 10000 rpm and shear for 30 min. have to. Among them, the inner core water phase: hydrophobic silica = 12 : 1 (w / w), and the prepared dry water particle size is 20 μm ~ 300 μm. The obtained dry water powder is passed through a 60-mesh sieve for subsequent use.

[0054] 2. Preparation of drug granules: mix ibuprofen powder and lactose evenly at a mass ratio of 7:3 (w / w), use 5% HPC aqueous solution as a binder, and add an appropriate amount of binder to make a soft material, 60 mesh Sieves are used for granulation. The wet granules were dried in an oven at 60°C for 30 min and then taken out, and the drug granules with a particle size of 60-100 mesh were screened for use.

[0055] 3. Ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com