Cream composition and preparation method thereof

A composition and cream technology, applied in cream preparations, dairy products, applications, etc., can solve problems such as poor spreadability and unsuitability for non-dairy cream, achieve good shape retention, reduce intake risk, and wide pH application range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0127] Next, the present invention will be described in further detail through examples, but the present invention is not limited to these examples.

[0128] In an embodiment of the present invention, the physical and chemical properties of the gliadin composition and its use performance are determined by the following methods:

[0129] Determination of wetting angle: Use an infrared tablet press to compress 1g of the sample to be tested (30MPa) to obtain a sheet-like sample with a diameter of 13mm and a thickness of 2mm, and then put it into a fully automatic contact angle measuring instrument (Zhongchen Digital Technology Equipment Co., Ltd. , JC2000D4M) on the stage, use 2μL pure water droplet and take pictures to measure the wetting angle.

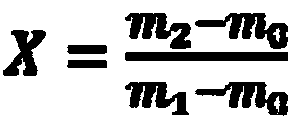

[0130] Determination of instant solubility: Disperse 10 grams of protein powder with a dry content of D% in 180 grams of deionized water at 24 °C ± 1 °C, and stir with a bench mixer at a speed of 400 rpm. After stirring for 10 minutes...

preparation example 1

[0144] (1) Raw material dissolution: 50 parts by weight of zein (α-gliadin, β-gliadin and γ-gliadin account for 97wt%, 2wt% and 0% of gliadin respectively) are completely dissolved in In 375 parts by weight of 70v / v% ethanol solution at 50°C, the pH was adjusted to 6 to obtain the first feed solution.

[0145] (2) 25 parts by weight of dextrin were completely dissolved in 987 parts by weight of water to obtain a second feed liquid.

[0146] (3) Primary reverse phase precipitation: 250 parts by weight of 40v / v% ethanol (50°C) was added to the first feed liquid obtained in step (1), and stirred rapidly, and stirred and kept at 50°C for 30min, A reversed-phase precipitate was obtained.

[0147] (4) Secondary reverse-phase precipitation: Add the primary reverse-phase precipitation in step (3) to the second material liquid obtained in step (2) and stir for rapid dispersion. The reaction temperature is controlled at 15°C, and the pore size is 100 μm. After the filter cloth removes...

preparation example 2

[0151] (1) Dissolving raw materials: 60 parts by weight of zein (alpha-gliadin, beta-gliadin and gamma-gliadin respectively account for 90wt%, 5wt% and 1wt% of the prolamin), 7 wt% Parts of glycerol and 3 parts by weight of polyethylene glycol were completely dissolved in 450 parts by weight of 70v / v% ethanol solution at 45°C, and the pH was adjusted to 2.8 to obtain the first feed solution.

[0152] (2) 18 parts by weight of chitosan were completely dissolved in 1184 parts by weight of water to obtain a second feed liquid.

[0153] (3) One-time reverse phase precipitation: 300 parts by weight of 40v / v% ethanol (45°C) was added to the first feed liquid obtained in step (1), and stirred rapidly, and kept at 45°C for 30min to obtain A reverse phase eluate.

[0154] (4) Secondary reverse phase precipitation: Add the primary reverse phase precipitation solution in step (3) to the second material liquid obtained in step (2) and stir to make rapid dispersion. The reaction temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com