A kind of preparation method and application of magnetic nanometer inorganic arsenic adsorbent

A magnetic nanometer and magnetic nanoparticle technology, which is applied in inorganic chemistry, chemical instruments and methods, adsorption water/sewage treatment, etc., can solve the problems of poor anti-interference ability, narrow application range, and low adsorption efficiency, and achieve anti-interference ability Strong, low cost, high adsorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

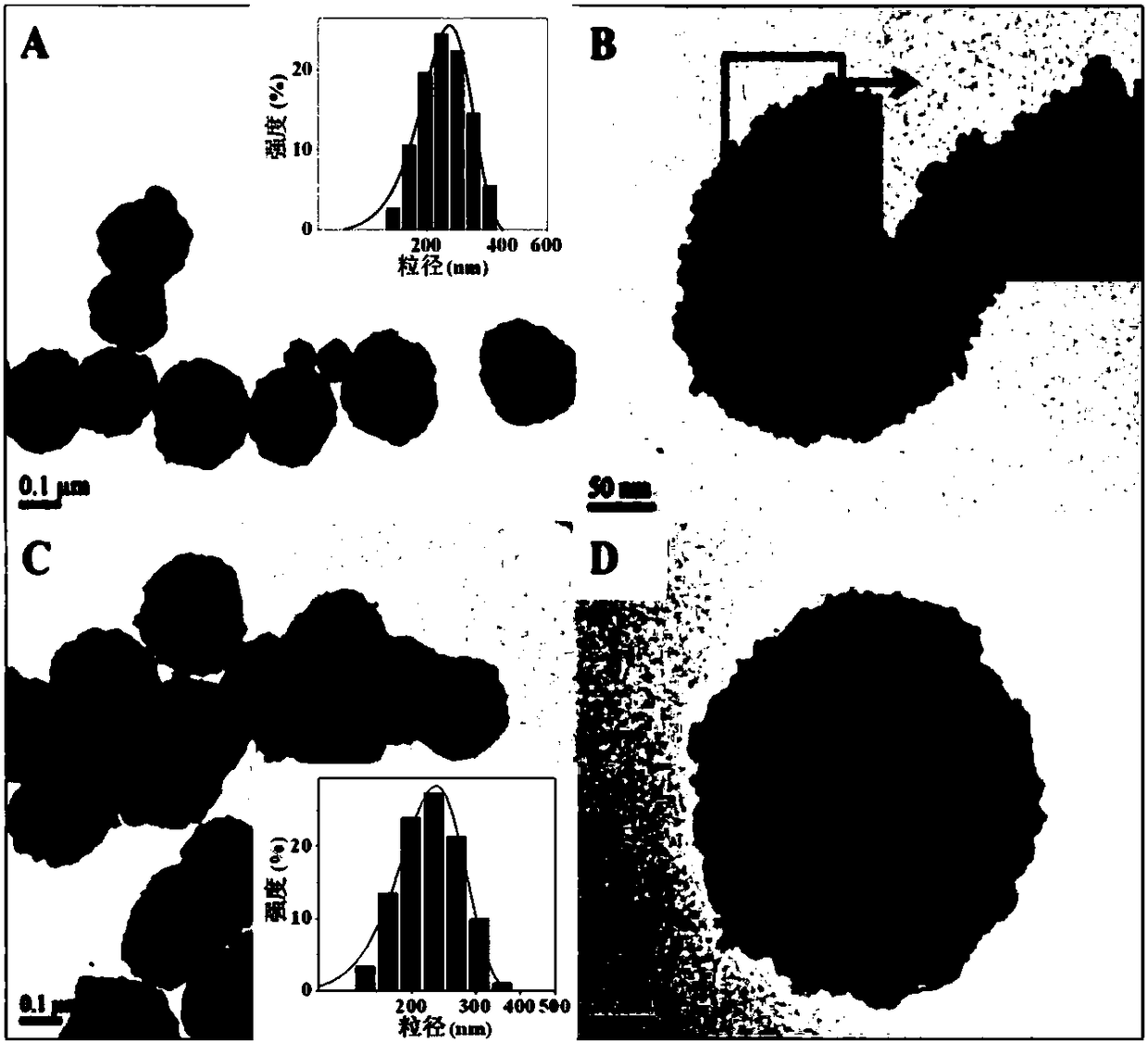

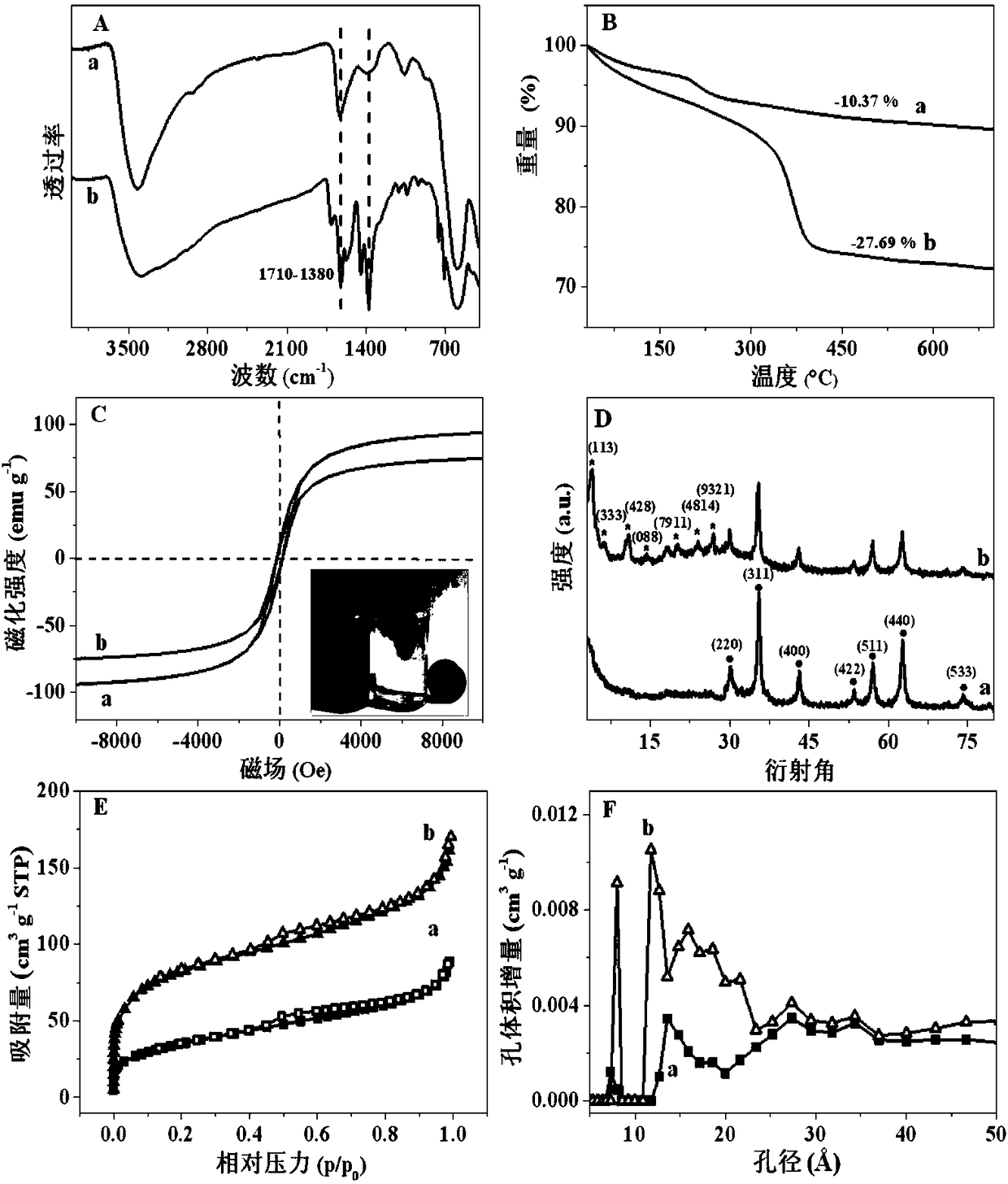

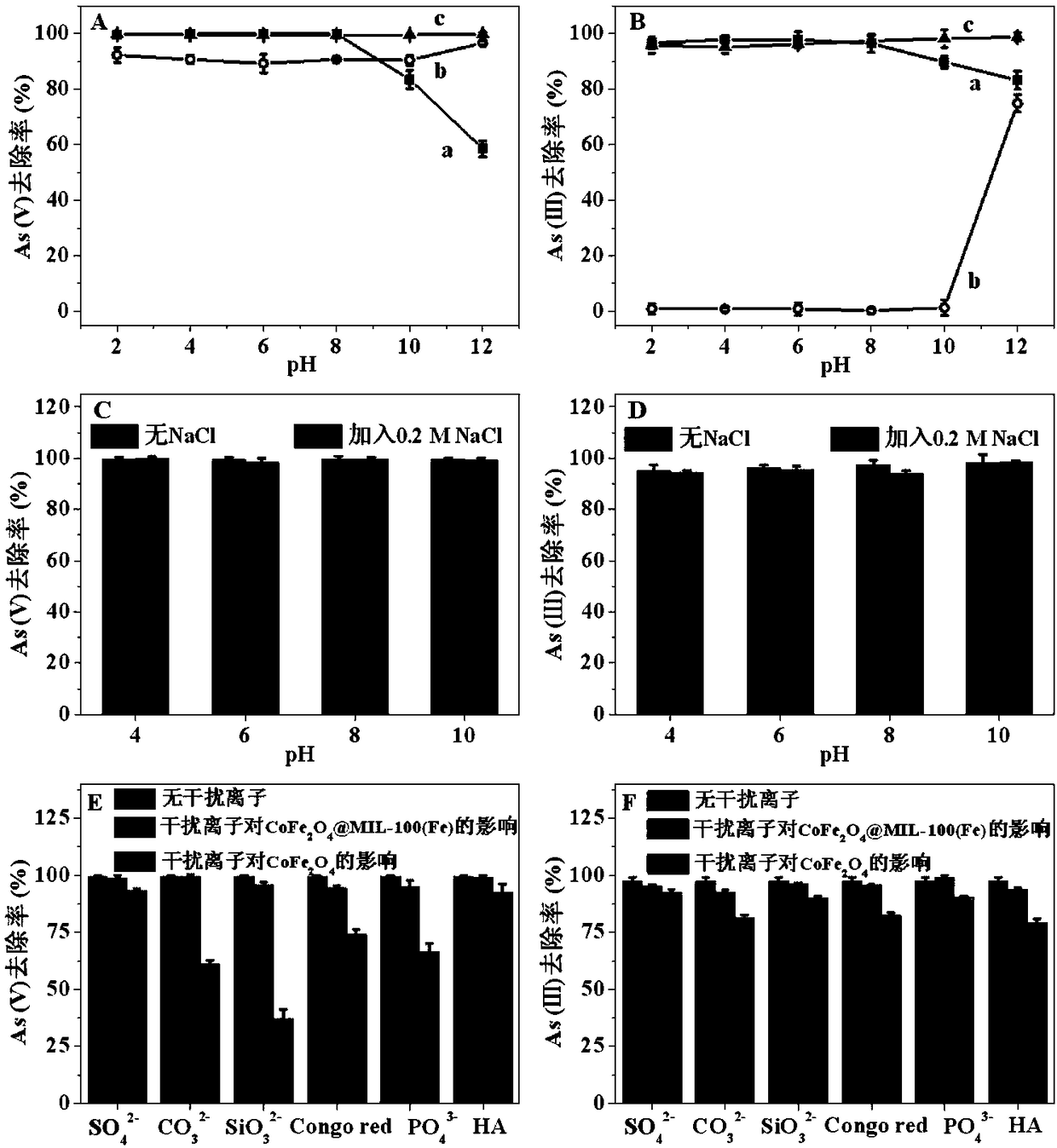

[0023] A preparation method of a magnetic nano-inorganic arsenic adsorbent, the magnetic nano-inorganic arsenic adsorbent is CoFe with a mesoporous core-shell structure 2 o 4 @MIL-100(Fe), the steps are as follows:

[0024]1) Dissolve 148.7mg of cobalt chloride, 337.9mg of ferric chloride, 900.0mg of sodium acetate, and 500.0mg of polyethylene glycol-6000 in 10mL of ethylene glycol, stir at 50°C for 20 minutes to form a uniform brown solution, and transfer to into the reactor, 160 ° C hydrothermal reaction for 16 hours, the obtained black precipitate was magnetically separated and washed twice with ethanol and water, and dried in vacuum to obtain mesoporous CoFe 2 o 4 magnetic nanoparticles;

[0025] 2) 50mg of the above mesoporous CoFe 2 o 4 Add magnetic nanoparticles to 10mL 0.58mM ethanol solution of mercaptoacetic acid (MAA), under nitrogen protection, stir at room temperature for 24 hours for surface modification, wash the remaining mercaptoacetic acid on the surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com