A non-degenerate polarized entangled source system using periodically polarized lithium niobate thin film waveguide and its working method

A periodically polarized, thin-film waveguide technology, applied in the field of quantum information, can solve the problems of large device size, unfavorable large-scale popularization, high instrument cost, etc., and achieves the effect of compact device structure, saving research funds, and small device volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] A nondegenerate polarization entanglement source system utilizing periodically poled lithium niobate thin-film waveguides, such as figure 1 As shown, it includes a laser 1, a first half-wave plate 2, a dichroic mirror 3, a first detector 4, a second detector 5, a polarization beam splitter 6, a second half-wave plate 7, and a first mirror 8. The second mirror 9, the periodically poled lithium niobate waveguide 10;

[0058] The laser 1, the first half-wave plate 2, the dichroic mirror 3, the polarizing beam splitter 6, the second half-wave plate 7, and the second mirror 9 are sequentially arranged along the optical path; the dichroic mirror 3 is connected to the first detector 4; the polarization beam splitter 6 is connected to the second detector 5; the polarization beam splitter 6, the second half-wave plate 7, the second reflection mirror 9, the periodically poled lithium niobate waveguide 10, and the first reflection mirror 8 in sequence end-to-end connection;

[0...

Embodiment 2

[0070] A non-degenerate polarization entanglement source system using periodically poled lithium niobate film waveguide, the difference is:

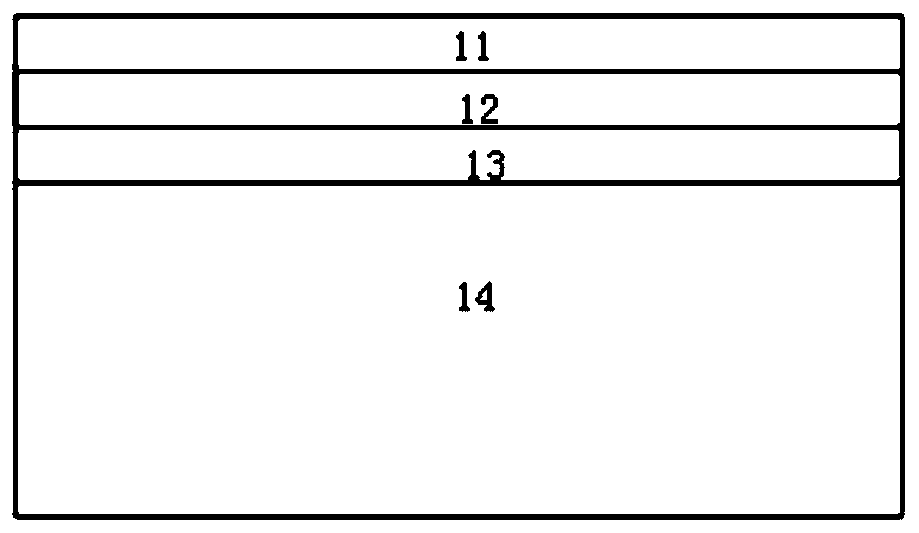

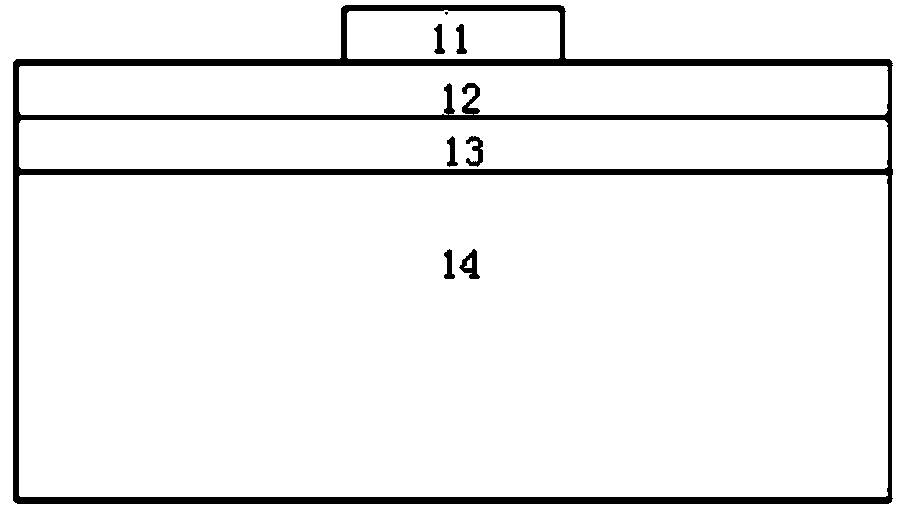

[0071] In step A, a lithium niobate film 12 with a thickness of 400 nm is grown on a silicon dioxide layer 13 with a thickness of 20 μm; in the step B, a lithium niobate film 12 is deposited on the surface of the lithium niobate film 12 by magnetron sputtering Chromium layer 11 with a layer thickness of 600 nm.

[0072] In step F, the sample is placed on a piezoelectric platform with an XY axis with a precision of 7nm, and the objective lens is placed on a piezoelectric platform with a z-axis with a precision of 100nm, the numerical aperture of the objective lens is NA=0.7, and the magnification of the objective lens is 100 times. The objective produces a laser spot of 800nm-2μm. The light spot emitted from the laser 1 is about 200 microns, passes through a lens with a focal length of 4 mm, and then passes through an objective lens with...

Embodiment 3

[0076] A non-degenerate polarization entanglement source system using periodically poled lithium niobate film waveguide, the difference is that in step F, a 1 μm laser spot is generated by using the objective lens.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com