Technology for preheating garbage storage by using boiler air supply

A technology for garbage storage and boiler, applied in incinerators, combustion methods, combustion types, etc., can solve the problems of low garbage fermentation efficiency, complex system, corrosion and leakage of radiators, etc., to shorten garbage fermentation time, improve garbage fermentation efficiency, The effect of reducing environmental risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

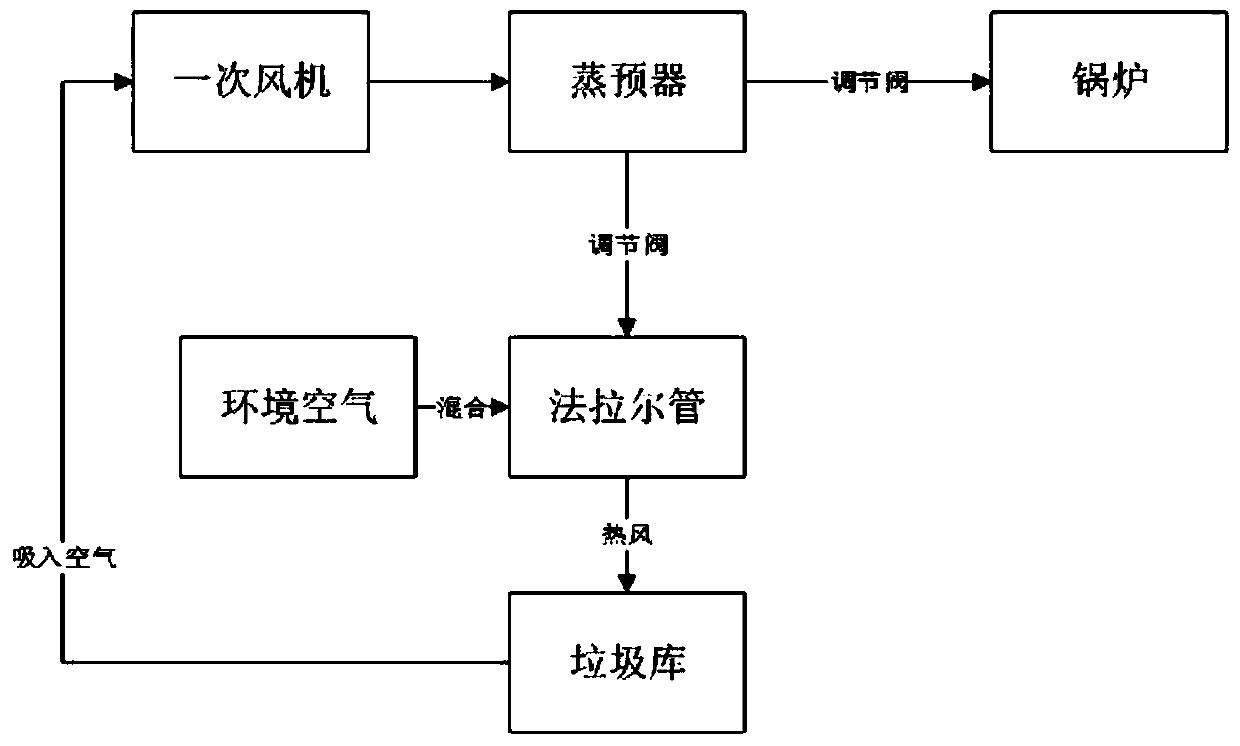

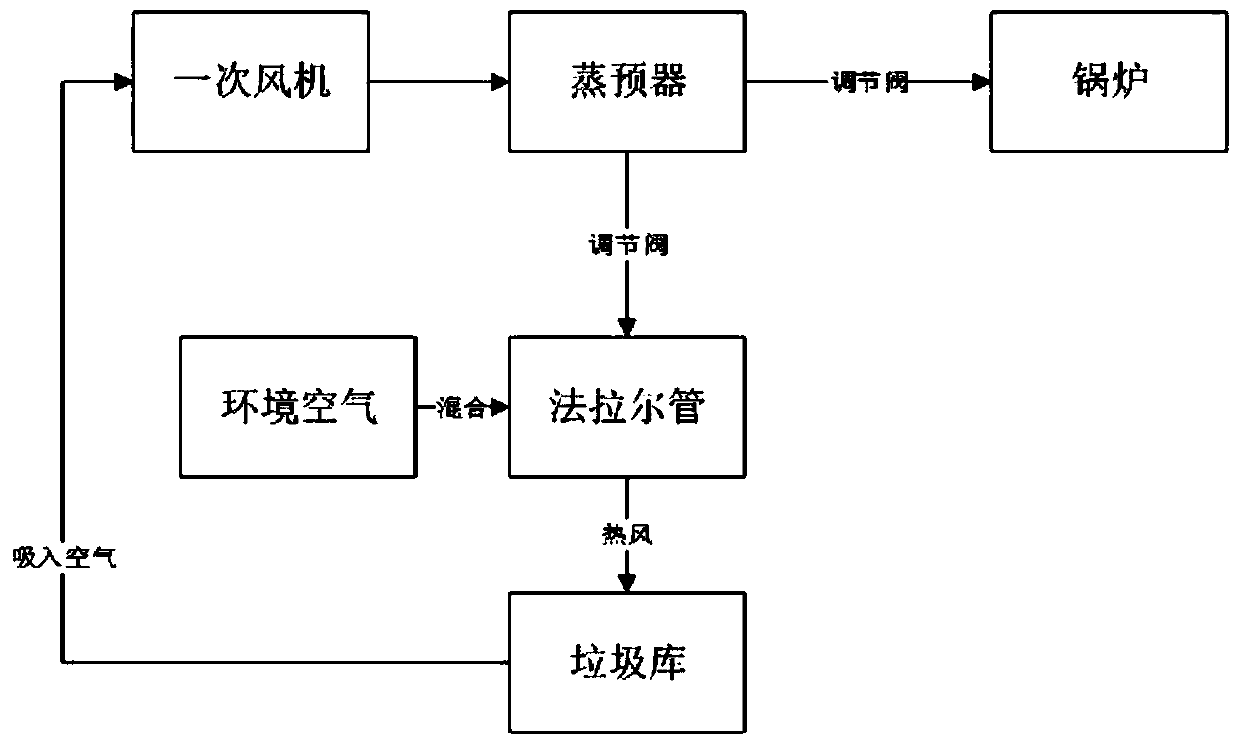

Embodiment 1

[0043] After passing through the primary fan steam preheater, the main pipe opens a bypass air duct, and a regulating valve is set on the bypass air duct to control its air volume. Then it is divided into 12 small air ducts on the main pipe, and enters the garbage storage from the side wall above the unloading platform and the front wall of the garbage storage. 4 on each side wall and 4 on the front wall. The height through the front wall is about 15M, and the left and right side walls can be slightly higher at about 20M. It is necessary to reasonably avoid the concentrated garbage storage area, and avoid hot air blowing directly on a piece of garbage. At this time, the primary fan sucks air from the top of the garbage bin, and the air is heated to about 200°C by the preheater, and about 5-30% of the high-temperature hot air is sent to the heating pipeline of the garbage bin. The hot air volume can be adjusted with a regulating valve. The farrell tube (similar to the steam e...

Embodiment 2

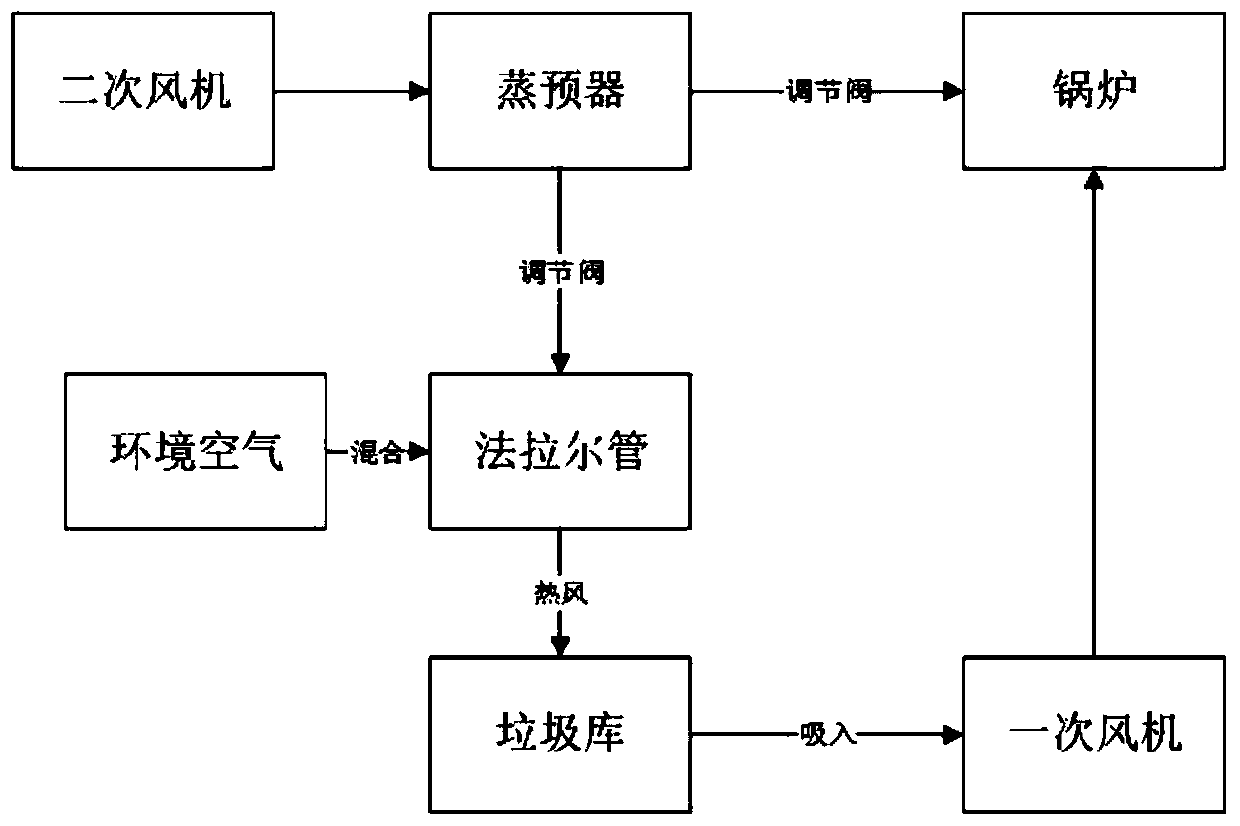

[0045] Utilize the secondary air and the secondary air steam preheater, set up a bypass air duct through the main pipe behind the secondary fan steam preheater, and set a regulating valve on the bypass air duct to control its air volume. Then it is divided into 12 small air ducts on the main pipe, and enters the garbage storage from the side wall above the unloading platform and the front wall of the garbage storage. 4 on each side wall and 4 on the front wall. The height through the front wall is about 15M, and the left and right side walls can be slightly higher at about 20M. It is necessary to reasonably avoid the concentrated garbage storage area, and avoid hot air blowing directly on a piece of garbage. At this time, the primary fan sucks in air from the top of the garbage store, and the air is heated to about 200°C through the steam preheater. The air volume of the hot air entering the garbage store and the boiler can be adjusted with a regulating valve, and then passes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com