Self-compensation intelligent lip-shaped seal

A lip seal, self-compensating technology, used in engine seals, engine components, mechanical equipment, etc., can solve problems such as leakage, softening of rubber materials, hardening of rubber materials, etc., to achieve long life and good sealing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

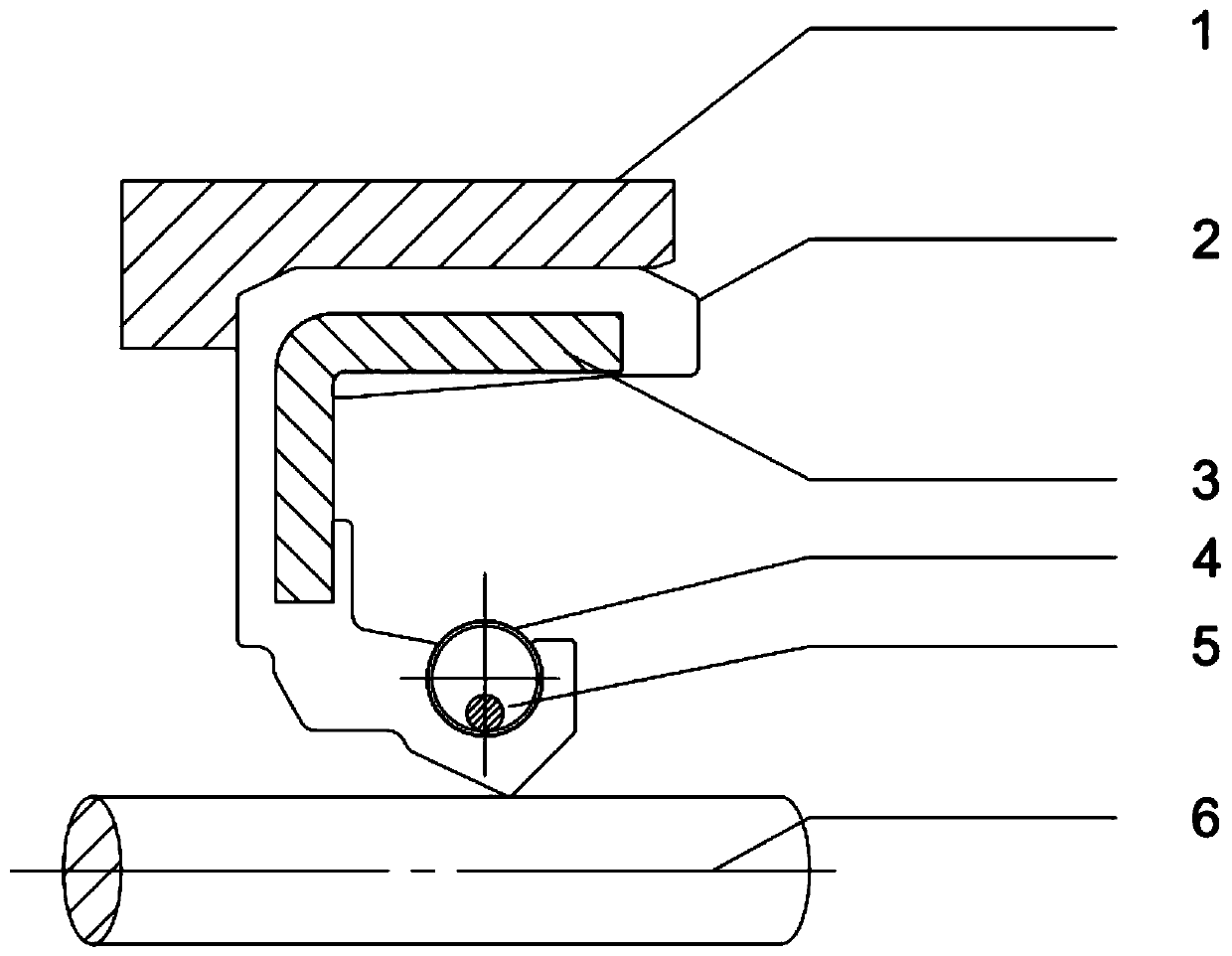

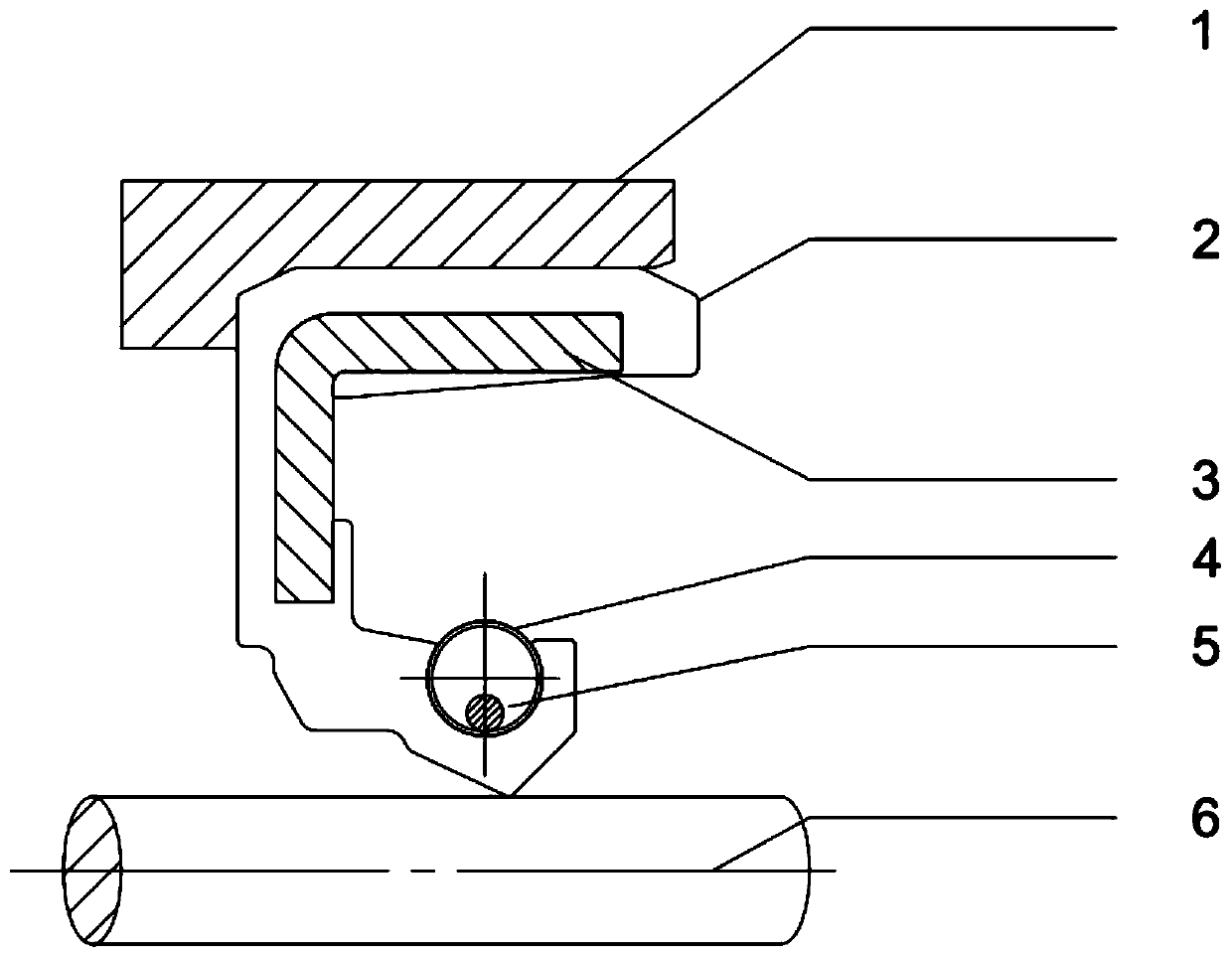

[0022] refer to figure 1 , a self-compensating intelligent lip seal, including a working chamber outer shell 1, a sealing ring body 2 with an interference fit with the working chamber outer shell 1, a metal skeleton 3 embedded in the sealing ring body 2, and the metal skeleton 3 is located on the The upper part of the sealing ring body 2 is arranged in a circumferential direction. The lower part of the sealing ring body 2 has a circumferential groove, and the annular ordinary metal spring 4 is inlaid in the groove. The ordinary metal spring 4 is nested with an SMA memory alloy ring 5. The lower part of the sealing ring body 2 and the radial rotating shaft 6 contacts.

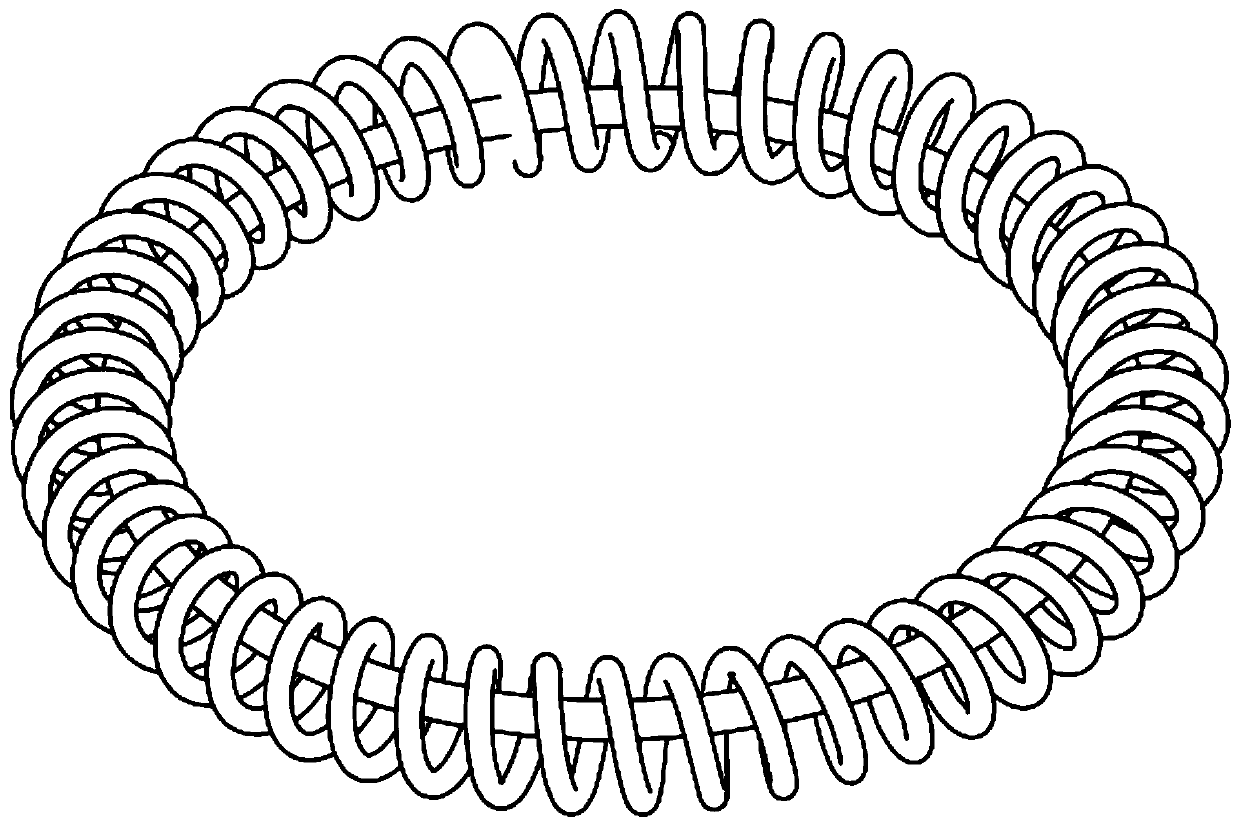

[0023] refer to figure 2 , the SMA memory alloy ring 5 is completely nested inside the ordinary metal spring 4, the inner, outer and wire diameters of the ordinary metal sprin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com