Novel ice skate blade drag reduction technology and implementation method thereof

An implementation method and ice blade technology, applied in ion implantation plating, metal material coating process, coating and other directions, can solve the problems of small surface roughness, reduced frictional resistance, limited drag reduction effect, etc., to reduce heat flow. The effect of distribution coefficient, reducing friction coefficient and improving heat flow distribution coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

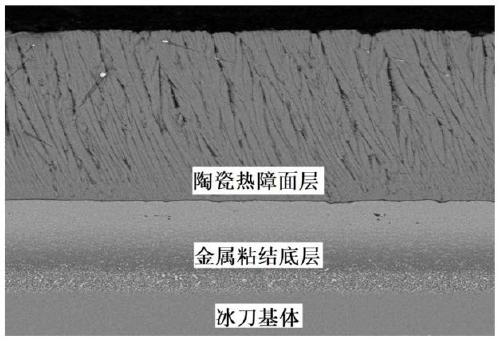

[0037] S110. Select 65Mn, a commonly used material for ice skates, to make a flat sample of 5mm×40mm×80mm, and perform surface pretreatment on the working surface of the flat sample: grinding—polishing—liquid sandblasting—ultrasonic cleaning—drying, after pretreatment The surface of the treated sample is clean, free of oil, and the surface roughness Ra<1.6μm, and it is ready for use;

[0038]S120, adopt A-1000 Vacuum Arc Ion-Plating Unit type arc ion plating vacuum physical vapor deposition (PVD) equipment, prepare NiCoCrAlYTa metal bonding bottom layer on the metal substrate after surface pretreatment; After cooling out of the furnace, the prepared Surface pretreatment of the metal bonding bottom layer: grinding - polishing - liquid sandblasting - ultrasonic cleaning - drying, the surface roughness of the pretreated sample is Ra<1.6μm, and it is ready for use;

[0039] S130. Use UE204B electron beam physical vapor deposition (EB-PVD) equipment to perform pre-oxidation treatme...

Embodiment 2

[0044] S210. Select 3Cr13, a common material for ice skates, to make a flat sample of 3mm×50mm×200mm, and carry out surface pretreatment on the working surface of the flat sample;

[0045] S220, using A-1000 Vacuum Arc Ion-Plating Unit type PVD equipment to prepare a metal bonding bottom layer on the metal substrate;

[0046] S230, after cooling out of the furnace, performing surface pretreatment on the metal bonding bottom layer;

[0047] S230. Use UE204B EB-PVD equipment to perform pre-oxidation treatment on the metal bonding bottom layer. The pre-oxidation treatment temperature is 1150°C, and the oxygen partial pressure is 1.5×10 -2 Pa, keep warm for 10h;

[0048] S240, then switch to the conventional EB-PVD coating program to prepare the YSZ ceramic thermal barrier surface layer on the metal bonded bottom layer, the main process parameters are: workpiece speed 20r / min, workpiece temperature 1250°C, target steam incident angle 15° , The deposition time is 12 hours, after ...

Embodiment 3

[0055] S310. Select the skates of Australian MAPLE speed skating skates as samples to be coated, and prepare flat samples of the same material of 2 mm × 10 mm × 10 mm to prepare coatings for surface characterization; Surface pretreatment of the working surface of the furnace plate sample;

[0056] S320, using A-1000 Vacuum Arc Ion-Plating Unit type PVD equipment to prepare the metal bonding bottom layer and perform surface pretreatment;

[0057] S330, use UE204B type EB-PVD equipment to pre-oxidize the metal bonding bottom layer, the pre-oxidation temperature is 1100 °C, and the oxygen partial pressure is 5.0×10 -3 Pa, keep warm for 10h;

[0058] S340. Then switch to the conventional EB-PVD coating program to prepare the YSZ ceramic thermal barrier surface layer on the metal bonded bottom layer. The main process parameters are: workpiece speed 5r / min, workpiece temperature 1170°C, target steam incident angle 0° , Deposition time 5h, after cooling out of the furnace, set asid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com