Non-toxic gold leaching agent and preparation method thereof

A gold leaching agent and transition metal technology, which is applied in the field of non-toxic gold leaching agent and its preparation in the gold dressing and smelting process, can solve the problems of corrosive agent dosage, high agent cost, and low gold leaching rate, and achieve agent consumption Small size, high air oxygen potential, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

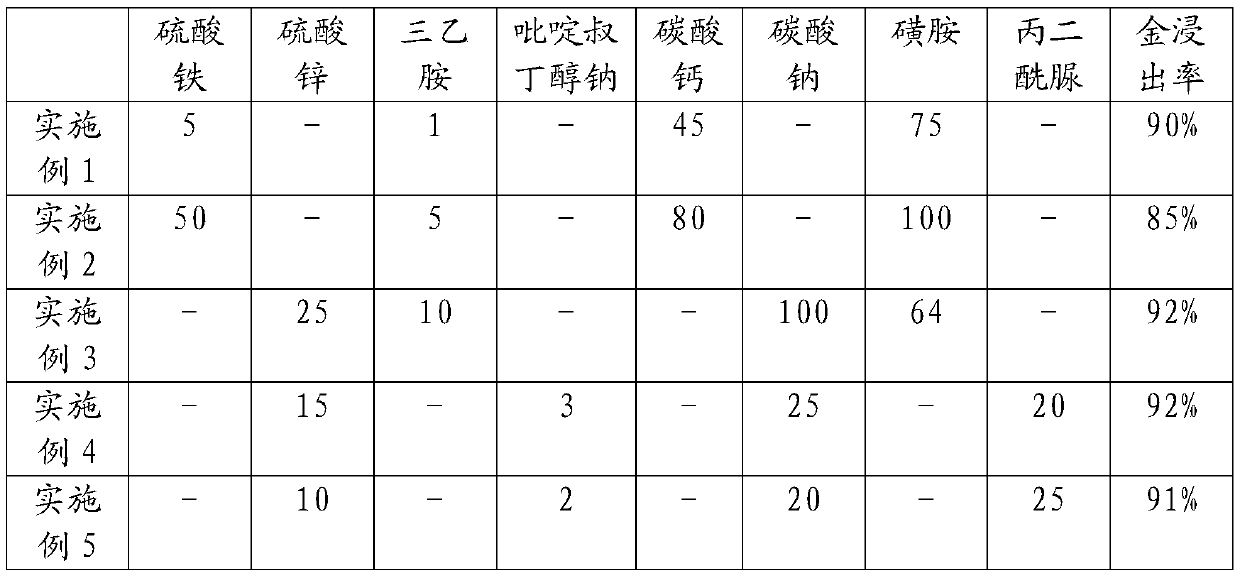

Embodiment 1

[0023] According to the mass ratio, 5 parts of iron sulfate, 1 part of triethylamine, 45 parts of calcium carbonate, and 75 parts of sulfonamide were uniformly mixed and finely ground to obtain a precursor. Place the precursor in an atmosphere muffle furnace, pass through oxygen-enriched air with an oxygen concentration of 60%, and raise the temperature to 600°C. After holding for 0.2h, the melt is taken out and air-cooled to solidify. After cooling to room temperature, finely grind to obtain a non-toxic gold leaching agent. The non-toxic gold leaching agent can directly replace sodium cyanide for use without changing the gold leaching process, and the gold leaching rate can reach more than 90%.

Embodiment 2

[0025] According to the mass ratio, 50 parts of iron sulfate, 5 parts of triethylamine, 80 parts of calcium carbonate, and 100 parts of sulfonamide were uniformly mixed and finely ground to obtain a precursor. Place the precursor in an atmosphere muffle furnace, pass through oxygen-enriched air with an oxygen concentration of 40%, and raise the temperature to 450°C. After holding for 0.1h, the melt is taken out and air-cooled to solidify. After cooling to room temperature, finely grind to obtain a non-toxic gold leaching agent. The non-toxic gold leaching agent can directly replace sodium cyanide for use without changing the gold leaching process, and the gold leaching rate can reach more than 85%.

Embodiment 3

[0027] According to the mass ratio, 25 parts of zinc sulfate, 10 parts of triethylamine, 100 parts of sodium carbonate, and 64 parts of sulfonamide were mixed and finely ground to obtain a precursor. Place the precursor in an atmosphere muffle furnace, pass through oxygen-enriched air with an oxygen concentration of 60%, and raise the temperature to 800°C. After holding for 0.2h, the melt is taken out and air-cooled to solidify. After cooling to room temperature, finely grind to obtain a non-toxic gold leaching agent. The nontoxic gold leaching agent can directly replace sodium cyanide for use without changing the gold leaching process, and the gold leaching rate can reach more than 92%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com