Self-repairing self-lubricating bifunctional anticorrosive coating and preparation method thereof

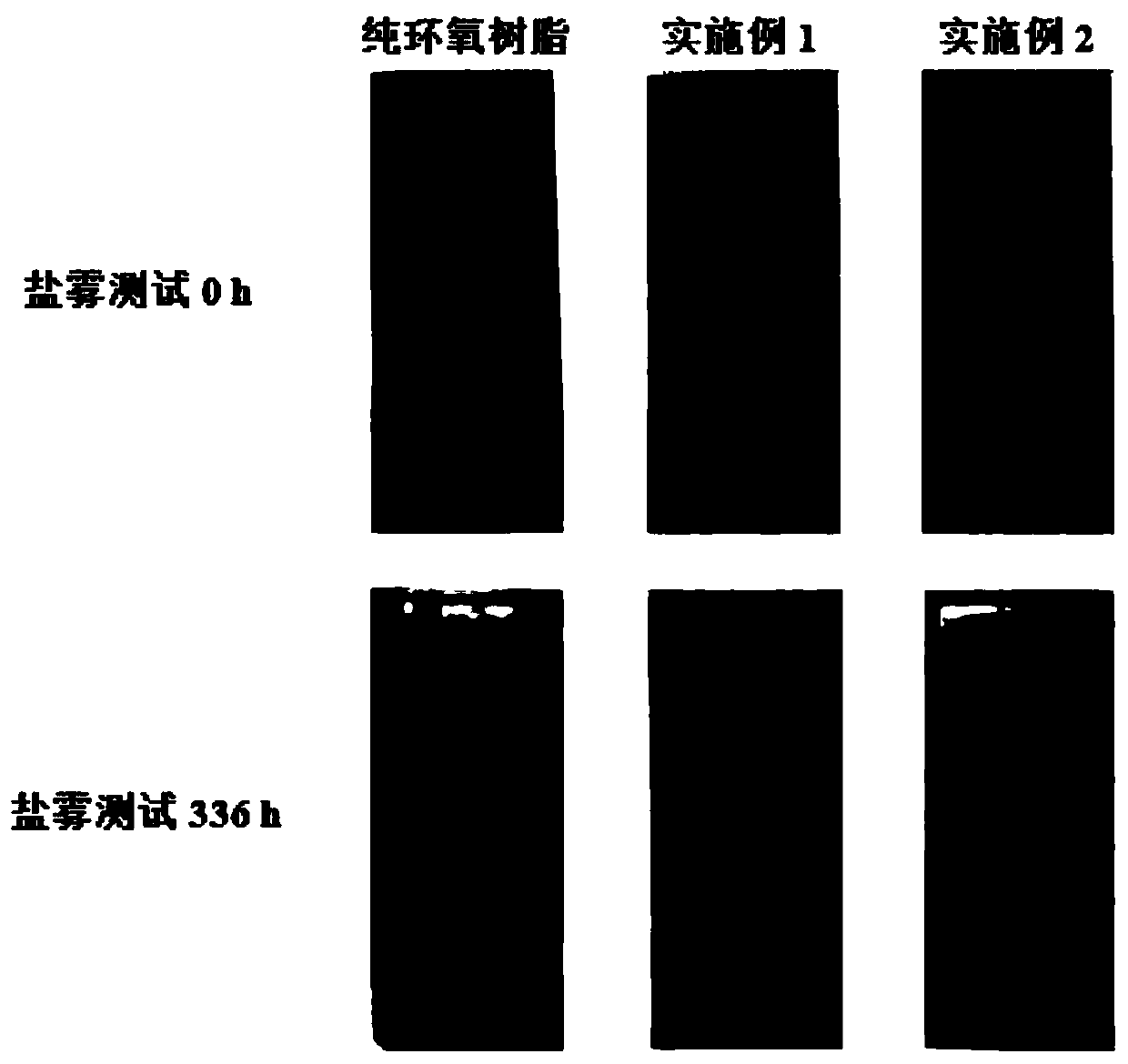

An anti-corrosion coating and self-healing technology, applied in anti-corrosion coatings, coatings, epoxy resin coatings, etc., can solve the problem of no dual-function anti-corrosion coating, and achieve the effect of smooth appearance, extended service life and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The self-healing and self-lubricating dual-function microcapsules include the following raw materials in parts by weight: 100 parts of water, 30 parts of linseed oil, 20 parts of solvent, 20 parts of emulsifier, 5 parts of isocyanate and 5 parts of polyol.

[0027] The preparation method of self-repairing, self-lubricating bifunctional microcapsules comprises the following steps:

[0028] (1) Mix water and emulsifier, continue to stir at room temperature for 60min, and the stirring rate is 1000rpm;

[0029] (2) Polyhydric alcohol is dissolved in 10 parts of water to obtain polyhydric alcohol aqueous solution;

[0030] (3) Mix the isocyanate with the solvent, add linseed oil after continuous stirring for 5 minutes, continue stirring for 5 minutes, and the stirring rate is 500 rpm;

[0031] (4) Add the mixed solution obtained in step (3) into the aqueous emulsifier solution obtained in step (1), and continue to stir for 10 minutes at a stirring rate of 1000 rpm;

[0032...

Embodiment 2

[0036] The self-healing and self-lubricating dual-function microcapsules include the following raw materials in parts by weight: 100 parts of water, 30 parts of linseed oil, 20 parts of solvent, 30 parts of emulsifier, 8 parts of isocyanate and 5 parts of polyol.

[0037] The preparation method of self-repairing, self-lubricating bifunctional microcapsules comprises the following steps:

[0038] (1) Mix water and emulsifier, continue to stir at room temperature for 60min, and the stirring rate is 1000rpm;

[0039] (2) Polyhydric alcohol is dissolved in 10 parts of water to obtain polyhydric alcohol aqueous solution;

[0040] (3) Mix the isocyanate with the solvent, add linseed oil after continuous stirring for 5 minutes, continue stirring for 5 minutes, and the stirring rate is 500 rpm;

[0041] (4) Add the mixed solution obtained in step (3) into the aqueous emulsifier solution obtained in step (1), and continue to stir for 10 minutes at a stirring rate of 1500 rpm;

[0042...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com