Solid flame retardant polymer, electrode slice, diaphragm and lithium secondary battery

A technology for flame-retardant polymers and lithium secondary batteries, applied in secondary batteries, secondary battery repair/maintenance, lithium batteries, etc., can solve the negative impact of battery electrochemical performance, increase electrolyte viscosity, Reaction and other issues, to achieve the effects of unaffected cycle performance, improved battery safety, and excellent flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] A kind of solid flame retardant polymer, its molecular structural formula is as shown in formula (A):

[0079]

[0080] The preparation of the solid flame-retardant polymer (polyethoxy (pentafluoro) cyclotriphosphazene) of the present embodiment:

[0081] Add 2.0 mol of hexafluorocyclotriphosphazene and 300 mL of acetonitrile into a 500 mL three-necked flask, and slowly add 1.0 mol of sodium ethylene glycol in acetonitrile mixture dropwise through a constant pressure dropping funnel at 0°C. , stirred and reacted at 40°C for 24 hours, filtered, and dried under reduced pressure to obtain polyethoxy(pentafluoro)cyclotriphosphazene (A), specifically n was 36.

[0082] Preparation of positive electrode sheet for lithium secondary battery:

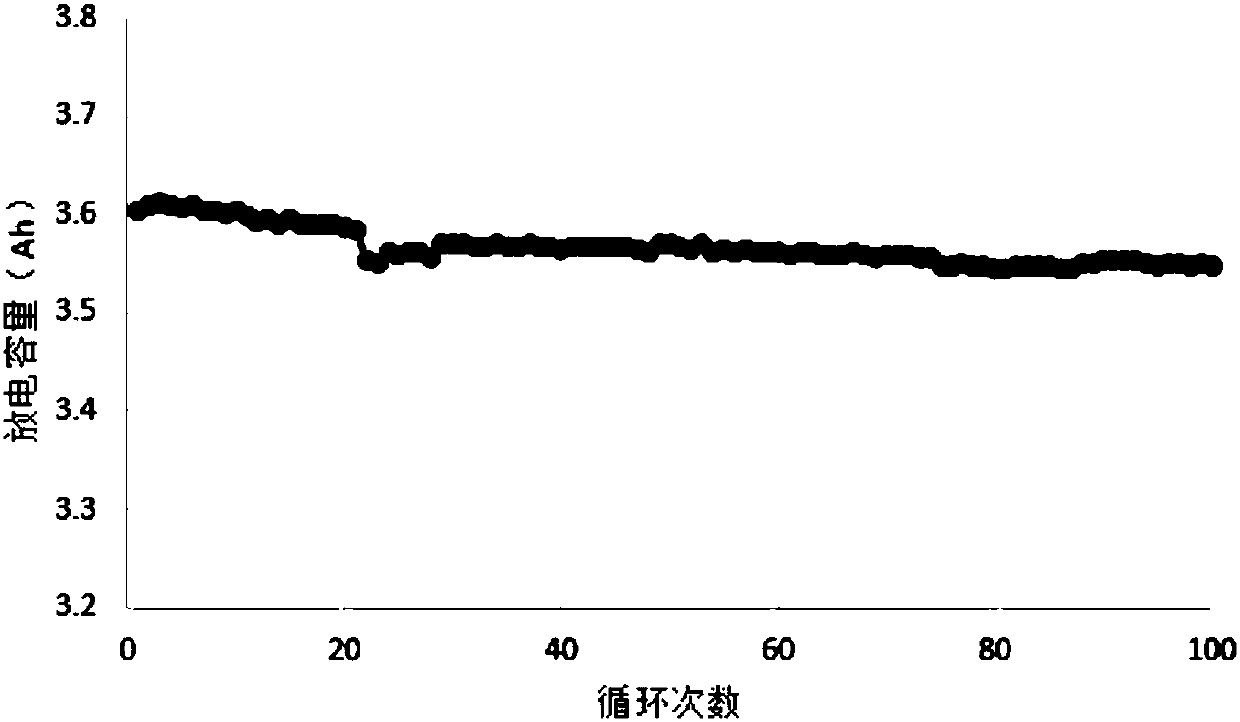

[0083] Weighing 2% polyvinylidene fluoride (PVDF), 2% conductive agent super P, 2% solid flame-retardant polymer A and 94% lithium cobaltate (LiCoO 2 ), sequentially added to N-methylpyrrolidone (NMP), fully stirred and mixed evenly, t...

Embodiment 2

[0088] A kind of solid flame-retardant polymer, its molecular structural formula is as shown in formula (B):

[0089]

[0090] The solid flame retardant polymer (B) of this example can be prepared by a method similar to Example 1.

[0091] Add 1.0 mol of hexafluorocyclotriphosphazene and 200 mL of acetonitrile into a 500 mL three-necked flask, and slowly add 1.0 mol of sodium hydroquinone in acetonitrile mixture dropwise through a constant pressure dropping funnel at 0°C. Afterwards, stir and react at 60°C for 48 hours, filter, and dry under reduced pressure to obtain a solid flame-retardant polymer (B), specifically n 1 , n 2 , n 3 , n 4 Both are 12.

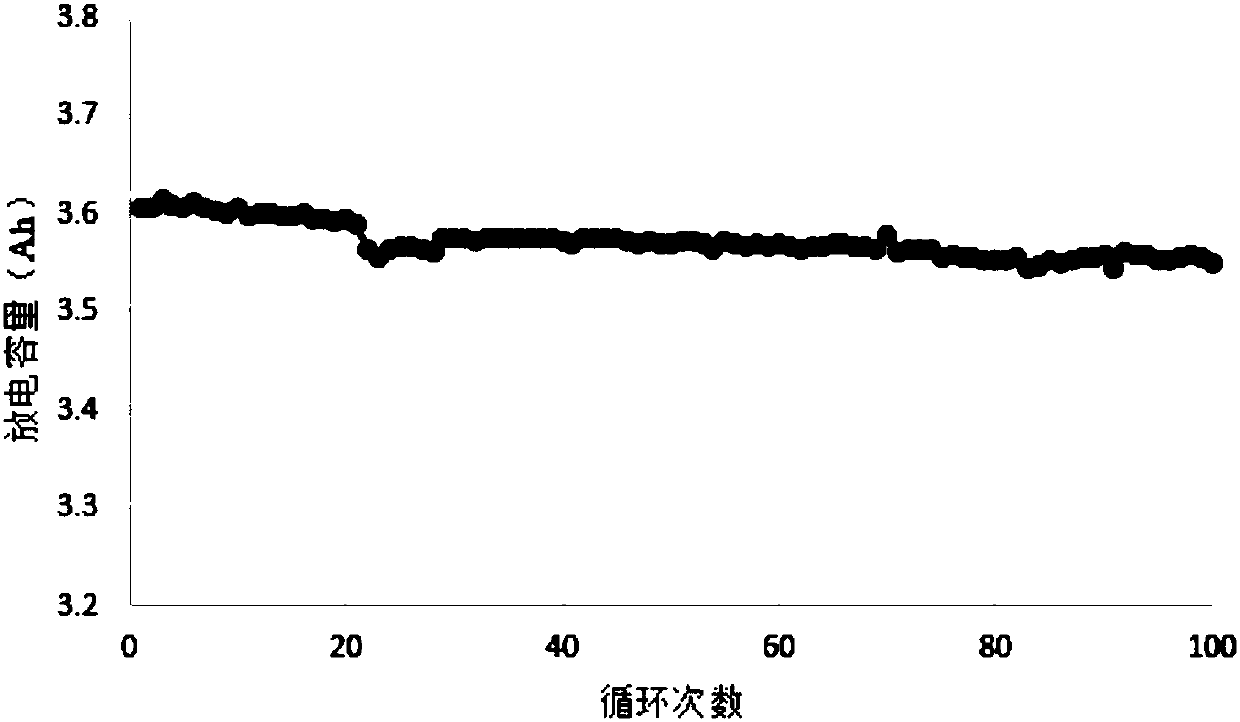

[0092] Preparation of positive electrode sheet for lithium secondary battery:

[0093] Weighing 2% polyvinylidene fluoride (PVDF), 2% conductive agent super P, 2% solid flame-retardant polymer B and 94% lithium cobaltate (LiCoO 2 ), sequentially added to N-methylpyrrolidone (NMP), fully stirred and mixed evenly, the sl...

Embodiment 3

[0098] A kind of solid flame retardant polymer, its molecular structural formula is as shown in formula (C):

[0099]

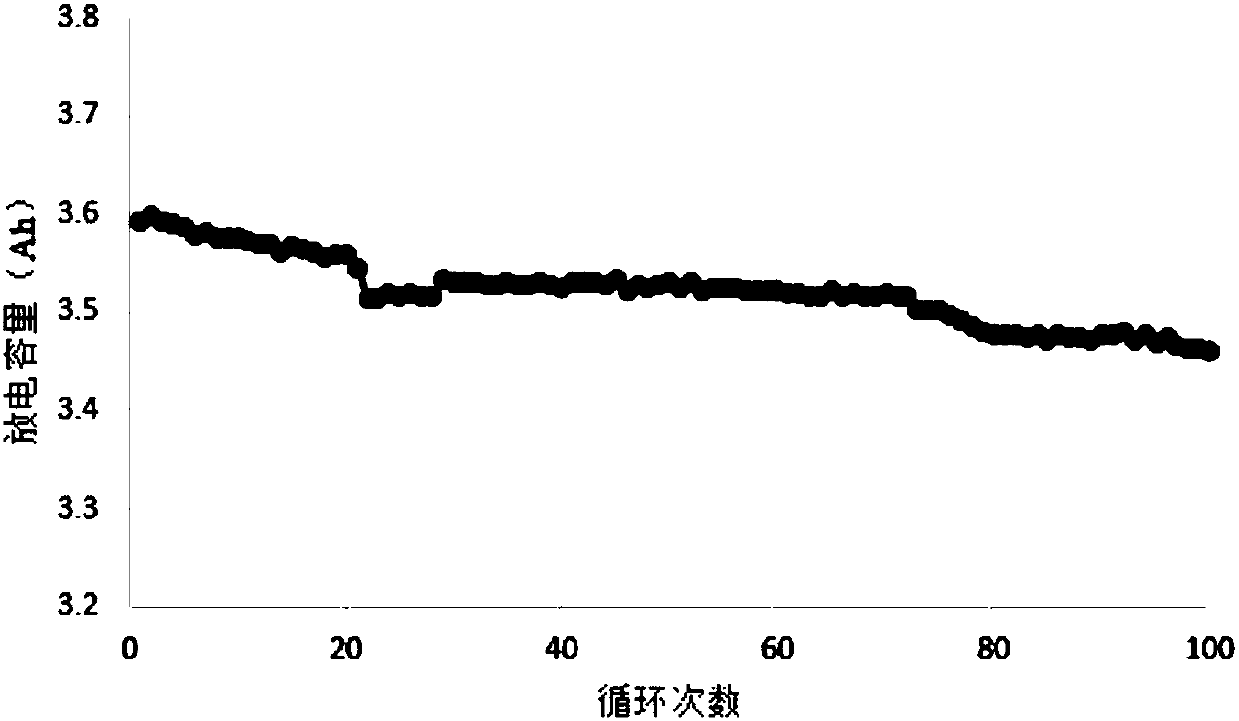

[0100] Preparation of the solid flame retardant polymer (polyethylene p-phenoxy (pentafluoro) cyclotriphosphazene) of the present embodiment:

[0101] Add 1.0mol hexafluorocyclotriphosphazene and 200mL acetonitrile respectively to a 500mL three-necked flask, and slowly add 1.0mol ethylene-p-phenol sodium acetonitrile mixture dropwise through a constant pressure dropping funnel at 0°C. , stirred and reacted at 30°C for 12 hours, filtered, and dried under reduced pressure to obtain the corresponding monomer ethylene-p-phenoxy (pentafluoro)cyclotriphosphazene. Then the corresponding monomer ethylene-p-phenoxy (pentafluoro)cyclotriphosphazene was dissolved in the acetonitrile solution containing the initiator (AIBN), polymerized at 60°C, and polyethylene-p-phenylene was obtained by dissolution-precipitation technology. Oxy(pentafluoro)cyclotriphosphazene (C),...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com