Aluminum ash recovering and reutilizing method

A technology for aluminum ash slag and filtering slag, which is applied in the field of aluminum ash slag recycling and reuse, can solve the problems of high aluminum ash slag recycling, low utilization rate, heavy environmental burden, etc., and achieve high-value utilization, realize utilization, and reduce pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

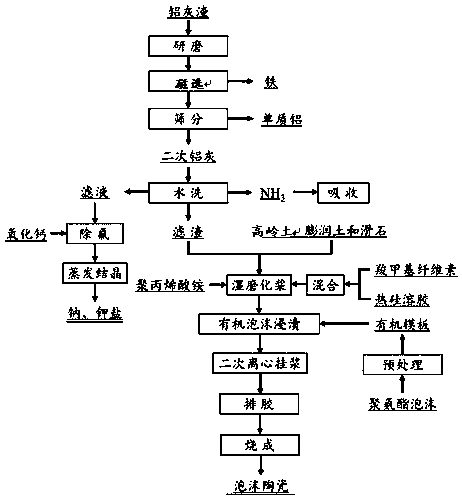

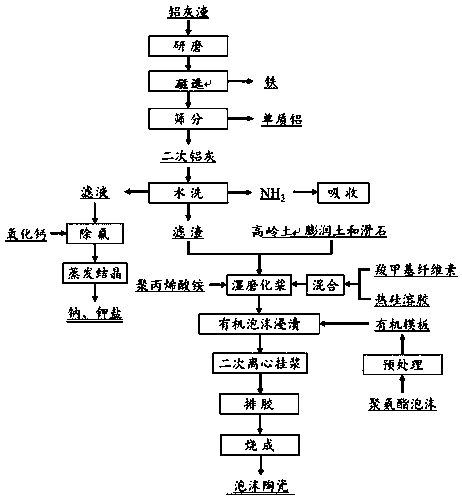

[0030] Aiming at the problems of high cost, low utilization rate, and burden on the environment in existing aluminum ash recycling or comprehensive utilization, the present invention discloses a recycling and reutilization method of aluminum ash, which can realize resource utilization of aluminum ash without It will pollute the environment, and the recycled filter residue is used to prepare foam ceramics to achieve high-value utilization. Such as figure 1 Shown, in this ceramic foam preparation method, comprise:

[0031] S1 The aluminum ash slag is rolled and ground, and iron impurities are separated by magnetic separation, and metal aluminum is separated by sieving to obtain secondary aluminum ash. In this process, in order to avoid re-oxidation and combustion of metal aluminum, the metal in the aluminum ash slag is pressed into sheets by rolling grinding. The average working pressure of rolling grinding is 60~100Mpa (MPa). The surface linear velocity is 0.2~1m / s (meter / sec...

Embodiment 1

[0037] After grinding the aluminum ash slag with an average working pressure of 60Mpa and a roller surface speed of 0.2m / s, the iron impurities are separated by magnetic separation, and then the elemental metal aluminum is separated by vibratory screening to obtain secondary aluminum ash , wherein the amplitude is 1.5mm, the vibration frequency is 800r / min, and the mesh aperture is 150μm.

[0038] The solid-liquid ratio is 1:5, the temperature is 80°C and the stirring speed is 200 r / min. Under certain conditions, the aluminum nitride in the secondary aluminum ash is decomposed and the salts are removed by washing with water. For the fluorine-containing filtrate produced by water washing, fluorine removal is carried out by adding 1% calcium oxide and stirring for 60 minutes, and then evaporating and crystallizing the defluoridation filtrate at 130°C to obtain sodium salt and potassium salt. At the same time, by The acid absorbs the ammonia gas decomposed by the aluminum nitrid...

Embodiment 2

[0044] After the aluminum ash is ground by rolling with an average working pressure of 70Mpa and a roller surface speed of 0.4m / s, the iron impurities are separated by magnetic separation, and then the elemental metal aluminum is separated by vibratory screening to obtain secondary aluminum ash , where the amplitude is 1.2mm, the vibration frequency is 900r / min, and the mesh aperture is 150μm.

[0045] The stirring speed is 220 r / min when the solid-liquid ratio is 1:8 and the temperature is 70°C. Under certain conditions, the aluminum nitride in the secondary aluminum ash is decomposed and the salts are removed by washing with water. For the fluorine-containing filtrate produced by water washing, fluorine removal is carried out by adding 2% calcium oxide and stirring for 50 minutes, and then evaporating and crystallizing the defluoridation filtrate at 120 ° C to obtain sodium salt and potassium salt. At the same time, by The acid absorbs the ammonia gas decomposed by the alum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com