A method for extracting lignin by ternary deep eutectic solvent

A deep eutectic solvent and lignin technology, applied in the field of high-efficiency utilization of biomass resources, can solve the problems of low lignin extraction, insufficient extraction purity, and poor effect, so as to reduce pretreatment costs, improve extraction efficiency, reduce Effects of Environmental Pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

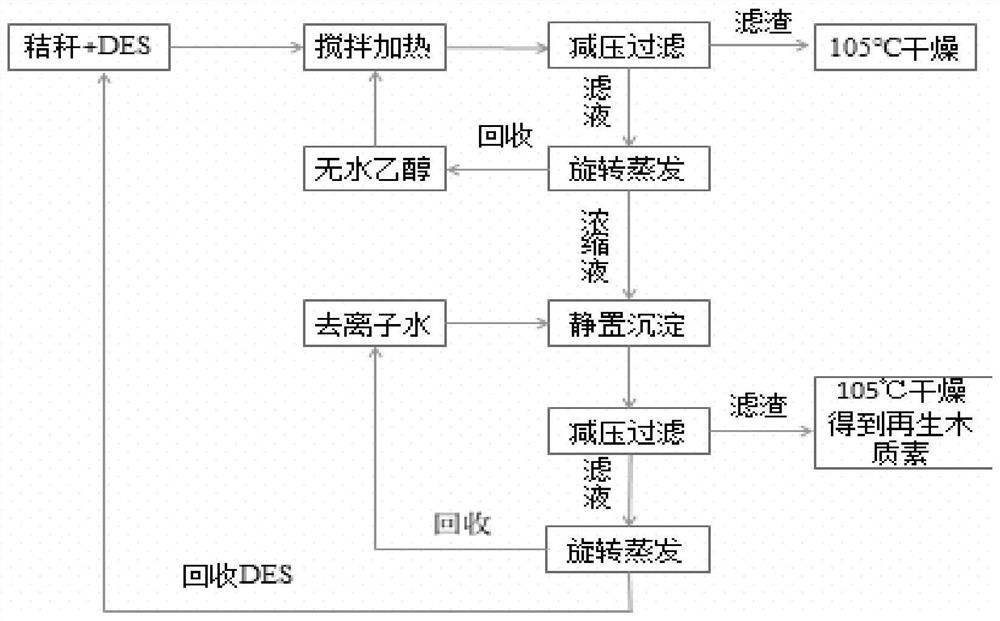

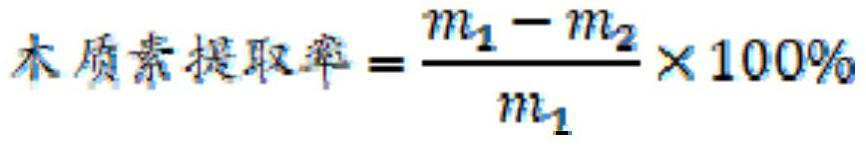

[0044] A method for extracting lignin using a ternary deep eutectic solvent, comprising the steps of:

[0045] S1. Crush the barley straw through a 60-mesh sieve, then dry it in an oven at 105°C, and add 2g of barley straw powder and 30g of DES(TE:GL:AlCl 3 ·6H 2 (2 molar ratio is 1:2:0.05), then it is transferred and placed in a constant temperature oil bath, the setting reaction temperature is 100°C, the rotating speed is 100rpm, and the reaction is 4h. After the reaction is completed, it is cooled to room temperature to obtain the reaction product.

[0046] S2. After reacting for 4 hours, cool the reaction vessel to room temperature, add 90ml of ethanol, then transfer the reaction vessel to a constant temperature magnetic stirrer, set the temperature to 60°C, the rotation speed to 100r / min, and the stirring time to 1h. Cool to room temperature, take out the reactant and perform suction filtration under reduced pressure, wash the filter residue with absolute ethanol, dry th...

Embodiment 2

[0049] A method for extracting lignin using a ternary deep eutectic solvent, comprising the steps of:

[0050] S1. Crush the barley straw through a 60-mesh sieve, then dry it in an oven at 105°C, and add 2g of barley straw powder and 30g of DES(TE:GL:AlCl 3 ·6H 2 O molar ratio is 1:2:0.1). Then it was transferred and placed in a constant temperature oil bath, the reaction temperature was set to 110°C, the rotation speed was 100rpm, and the reaction was carried out for 2 hours. After the reaction was completed, it was cooled to room temperature to obtain the reaction product.

[0051] S2. After reacting for 2 hours, cool the reaction vessel to room temperature, add 90ml of ethanol, then transfer the reaction vessel to a constant temperature magnetic stirrer, set the temperature to 60°C, the rotation speed to 150r / min, and the stirring time to 1h. Cool to room temperature, take out the reactant and perform suction filtration under reduced pressure, wash the filter residue with...

Embodiment 3

[0054] A method for extracting lignin using a ternary deep eutectic solvent, comprising the steps of:

[0055] S1. Crush the barley straw through a 40-mesh sieve, then dry it in an oven at 105°C, and add 2g of barley straw powder and 30g of DES(TE:GL:AlCl 3 ·6H 2 O molar ratio is 1:2:0.2). Then it was transferred and placed in a constant temperature oil bath, the reaction temperature was set to 130°C, the rotation speed was 150rpm, and the reaction was carried out for 3 hours. After the reaction was completed, it was cooled to room temperature to obtain the reaction product.

[0056] S2. After reacting for 3 hours, cool the reaction vessel to room temperature, add 90ml of ethanol, then transfer the reaction vessel to a constant temperature magnetic stirrer, set the temperature to 60°C, the rotation speed to 120r / min, and the stirring time to 2h. Cool to room temperature, take out the reactant and perform suction filtration under reduced pressure, wash the filter residue with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com