Process for reparation of rutile seed crystals from coarse-granularity hydrolysis abnormal material

A technology for preparing gold and rutile, which is applied in the fields of titanium oxide/hydroxide, inorganic chemistry, titanium dioxide, etc., can solve the problem that the performance of titanium dioxide pigment is greatly affected, the activity of rutile calcined seed crystals is low, the whiteness of oil phase, dry powder whiteness In order to achieve the effects of low cost, improved color index and decolorizing power, and long storage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

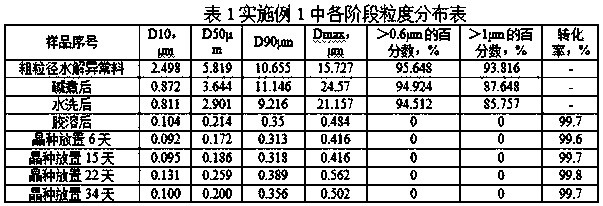

Embodiment 1

[0024] (1) Alkali cooking: Wash the metatitanic acid coupons of the coarse-grained hydrolyzed material with an average particle size of 6.190 μm, and wash until the Fe in the material 2+ The concentration of metatitanic acid is less than 50ppm, and the metatitanic acid is beaten to 325g / L, and the temperature is raised to 65°C to preheat to obtain the preheated metatitanic acid slurry, and then the mass fraction is 48% according to the molar ratio of alkali titanium to 1.6:1. Preheat the lye to 115°C, add the preheated metatitanic acid slurry to the lye, keep the temperature at 110°C, keep the mixed material slightly boiling, and mature for 2 hours; cool down to 70°C to generate sodium titanate ;

[0025] (2) Washing with water: the sodium titanate produced is hanged in a vacuum leaf filter, and the vacuum degree is adjusted to 0.04 MPa, and the sodium titanate leaf filter is washed with water at 30~40°C until the concentration of alkali in the filtrate is less than 1.5g / L, ...

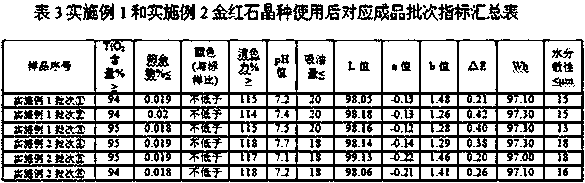

Embodiment 2

[0029] A process for preparing rutile seed crystals from hydrolyzed abnormal material with coarse particle size is characterized in that it comprises the following steps:

[0030] (1) Alkali cooking: Wash the metatitanic acid coupons of the coarse-grained hydrolyzed material with an average particle size of 7.29 μm, and wash until the Fe in the material 2+ The concentration of metatitanic acid is less than 50ppm, the metatitanic acid is beaten to 325g / L, and the temperature is raised to 60°C to preheat to obtain the preheated metatitanic acid slurry, and then the mass fraction is 48% according to the molar ratio of alkali titanium to 1.6:1 Preheat the lye to 115°C, add the preheated metatitanic acid slurry to the lye, keep the temperature at 110°C, keep the mixed material slightly boiling, and mature for 2 hours; cool down to 70°C to generate sodium titanate ;

[0031] (2) Washing with water: The sodium titanate produced is hanged in a vacuum leaf filter, and the vacuum degre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com