Z-type photocatalyst, preparation method and application thereof

A technology of photocatalyst and sulfide salt, applied in the field of photocatalysis, can solve the problems of large cadmium sulfide particle size, reduced reduction ability, poor uniformity, etc., and achieve the effect of simple and easy control, good crystallinity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

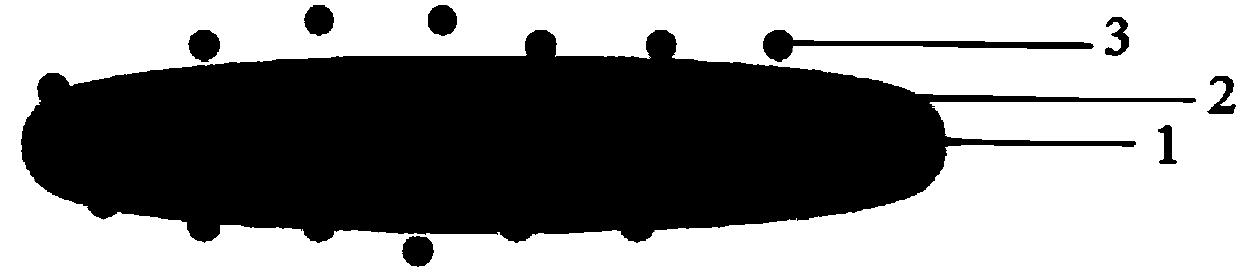

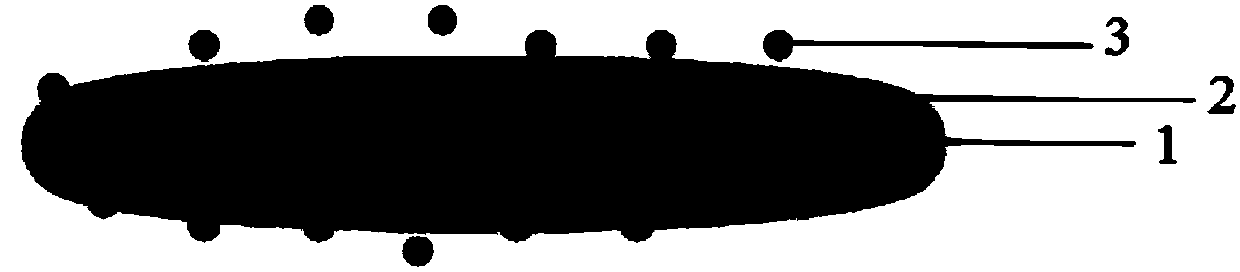

Image

Examples

preparation example Construction

[0040] In one embodiment, the preparation method of the Z-type photocatalyst at least includes the following steps:

[0041] S01. In C 3 N 4 Carry out coating treatment of carbon source in suspension liquid, prepare C 3 N 4 - carbon source;

[0042] S02. In an inert atmosphere, first charge the C 3 N 4 -Add mercapto acid and cadmium salt in the carbon source, then add sulfide salt thereinto, prepare C 3 N 4 - carbon source - CdS;

[0043] S03. Put the C 3 N 4 - Carbon source - CdS is calcined to convert the carbon source into a carbon layer to obtain a Z-type photocatalyst.

[0044] The technical solution of the present invention will be explained in detail below.

[0045] In step S01, C 3 N 4 of the suspension, involving C 3 N 4 The crystal form can be α-phase (α-C 3 N 4 ), β phase (β-C 3 N 4 ), cubic phase, quasi-cubic phase, graphite-like phase (g-C 3 N 4 ) in any one or several.

[0046] In step S01, C 3 N 4 The coating of the surface carbon source ...

Embodiment 1

[0083] A preparation method of Z-type photocatalyst, comprising the following steps:

[0084] S11. Take 5g of urea and put it into a 100mL porcelain crucible, cover it, and calcinate it at 500°C for 4h. After cooling to room temperature, grind the product finely in an agate mortar to obtain light yellow g-C 3 N 4 solid powder.

[0085] S12. Take 0.2000g g-C 3 N 4 , uniformly dispersed in 50mL ethanol solution, and ultrasonically dispersed for 2 hours to obtain g-C 3 N 4 Add 50 mg of dopamine hydrochloride to the suspension, and stir it magnetically for 6 hours. The suspension changes from milky white to brown, and g-C 3 N 4 - PDA suspension.

[0086] S13. To the g-C obtained in step S12 3 N 4 - Nitrogen gas was passed through the PDA suspension, 1 mL of thioglycolic acid was quickly added dropwise, stirred for 1 h, 5 mL of cadmium nitrate aqueous solution with a concentration of 1 mmol / L was slowly added, stirred for 10 min, and then 5 mL of a sodium sulfide aqueous s...

Embodiment 2

[0089] A preparation method of Z-type photocatalyst, comprising the following steps:

[0090] S21. Take 20g of melamine and put it into a 100mL porcelain crucible, cover it, and calcinate it at 600°C for 2h. After cooling to room temperature, grind the product finely in an agate mortar to obtain light yellow g-C 3 N 4 solid powder.

[0091] S22. Take 0.3000g g-C 3 N 4 , uniformly dispersed in 200mL methanol solution, and ultrasonically dispersed for 1h to obtain g-C 3 N 4 Add 200 mg of dopamine hydrochloride to the suspension, and stir it magnetically for 24 hours. The suspension changes from milky white to brown, and g-C 3 N 4 - PDA suspension.

[0092] S23. To the g-C obtained in step S22 3 N 4 - Nitrogen gas was passed through the PDA suspension, 5mL of thioglycolic acid was quickly added dropwise, stirred for 2h, 5mL of cadmium nitrate aqueous solution with a concentration of 1mmol / L was slowly added, stirred for 10min, then 5mL of a concentration of 50mmol / L sodi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com