Monatomic platinum doped nano porous metal compound catalyst and preparation method and application thereof

A metal compound and nanoporous technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as agglomeration and deactivation, and achieve low cost, simple and controllable preparation process, and environmental friendliness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

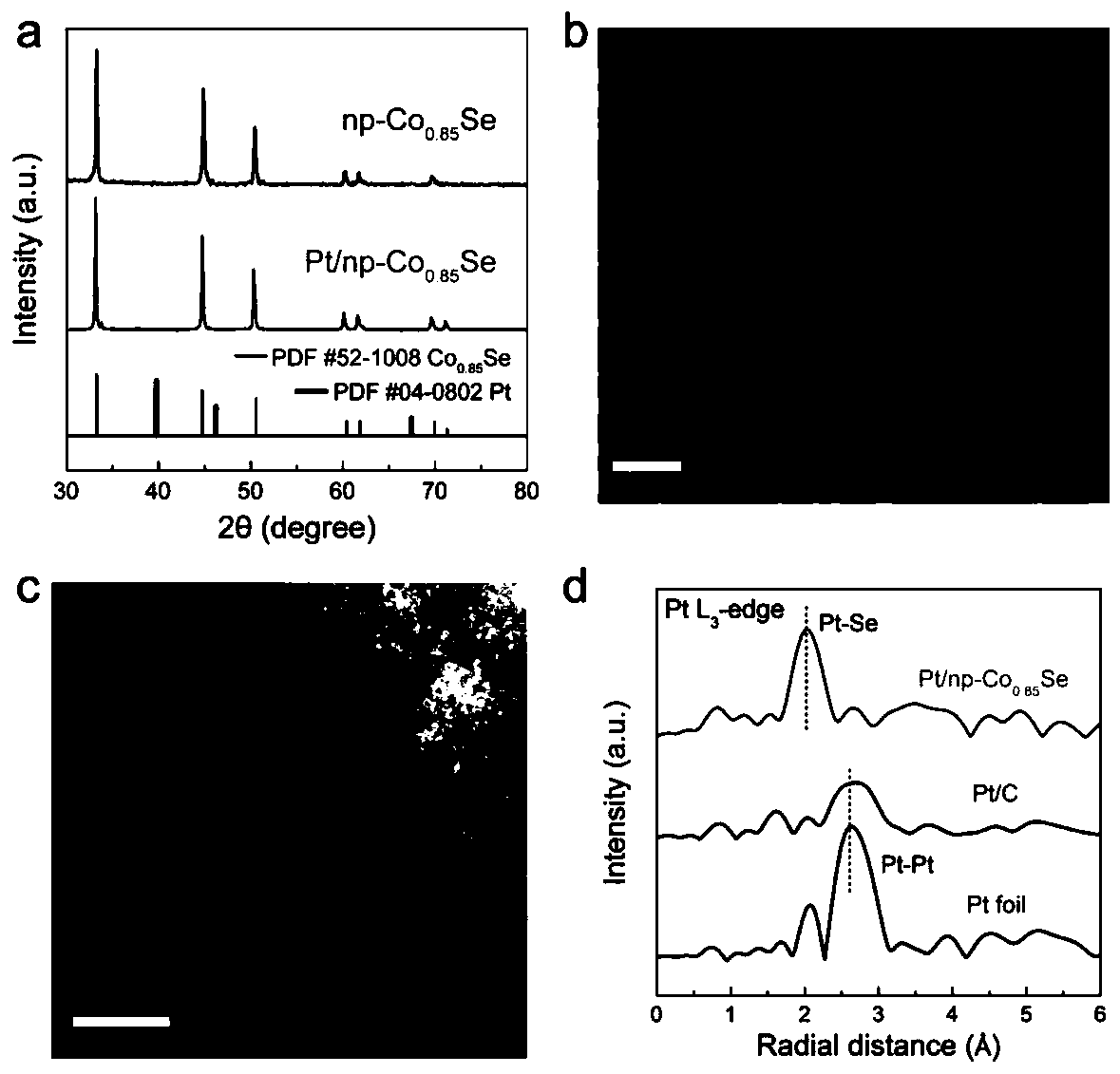

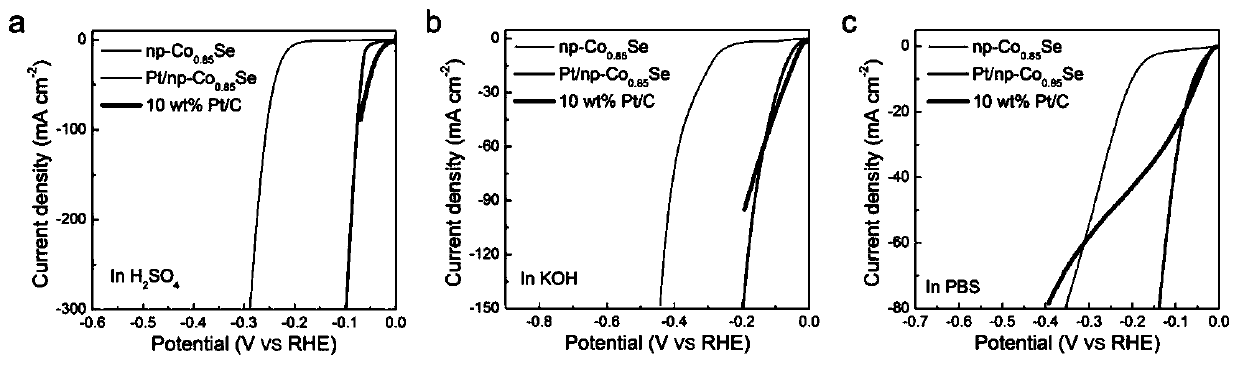

[0029] A certain proportion of pure cobalt grains and cobalt selenide (CoSe) was arc-melted in an argon atmosphere to prepare an alloy ingot (Co:Se=85:15), and then the alloy ingot was remelted and thrown to obtain a uniform nanocrystalline two-phase structure. alloy strips. Finally, the alloy strips were electrochemically etched using a sulfuric acid aqueous solution through the three-electrode system of the electrochemical workstation, and etched at a corrosion voltage of 0.00V vs. Ag / AgCl for 2000s to obtain nanoporous cobalt selenide strips.

[0030] Single-atom doping of nanoporous cobalt selenide by cyclic potential method using an electrochemical workstation. In the three-electrode system, the calibrated Ag / AgCl electrode was used as the reference electrode, the platinum sheet was used as the counter electrode, and the nanoporous cobalt selenide strip was used as the working electrode. 2 SO 4 as an electrolyte. When doping, the potential cycle range of the working el...

example 2

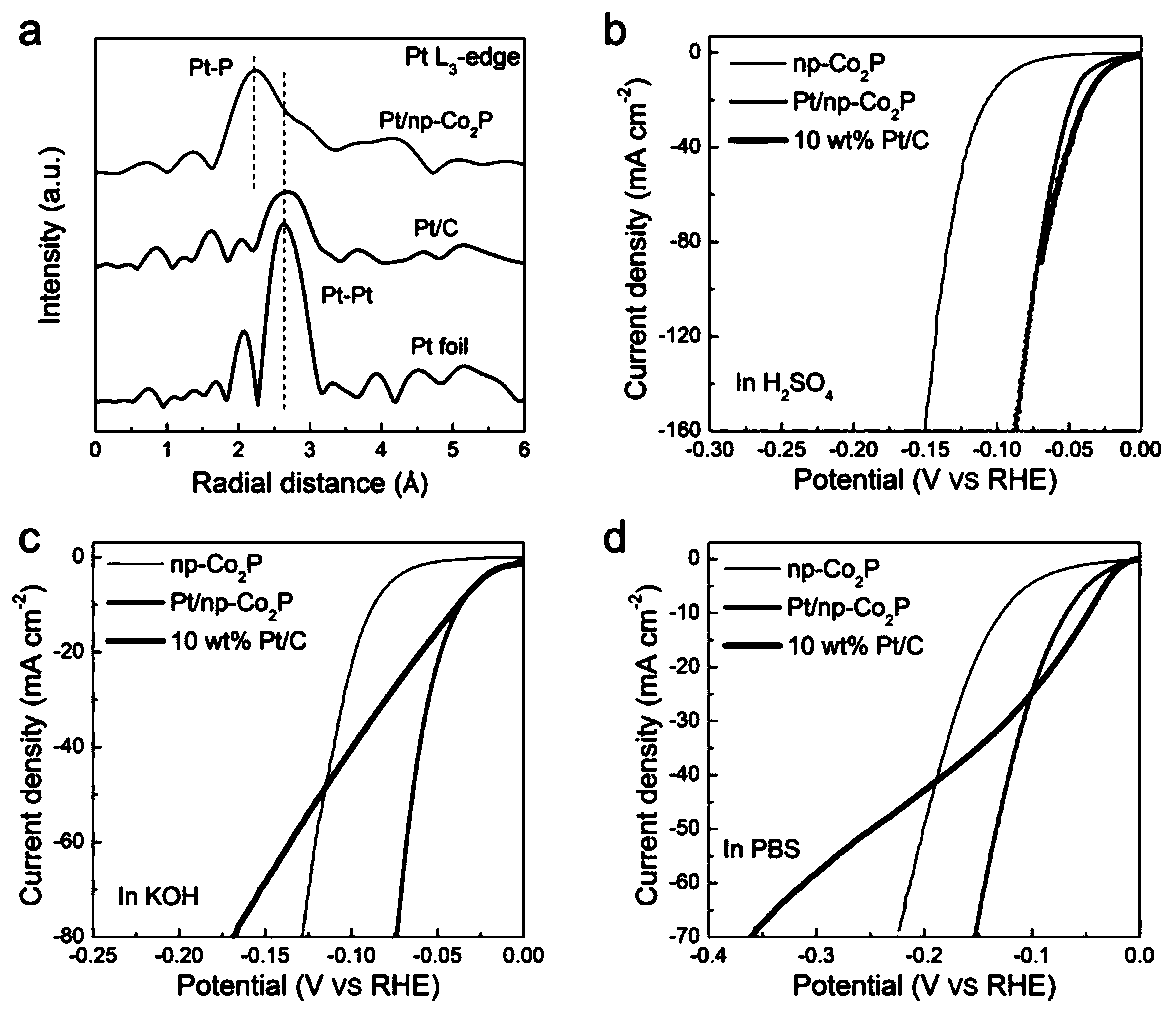

[0035] A certain proportion of pure cobalt grains and cobalt phosphide (CoP) was arc-melted in an argon atmosphere to prepare an alloy ingot (Co:P=85:15), and then the alloy ingot was remelted and thrown to obtain a homogeneous nanocrystalline two-phase structure. alloy strip. Finally, the alloy strips were electrochemically etched using sulfuric acid aqueous solution through the three-electrode system of the electrochemical workstation, and etched for 5000s at a corrosion voltage of 0.05V vs. Ag / AgCl to obtain nanoporous cobalt phosphide strips.

[0036] Using the same doped three-electrode system as in Example 1, using nanoporous cobalt phosphide as a working electrode, setting the same parameters as in Example 1 to perform single-atom platinum doping on nanoporous cobalt phosphide. Different cycle times can obtain single-atom platinum-doped nanoporous cobalt phosphide catalysts with different platinum loadings, among which the single-atom platinum-doped nanoporous cobalt ph...

Embodiment 3

[0040] Arc melting a certain proportion of pure cobalt grains and cobalt sulfide (CoS) in an argon atmosphere to prepare an alloy ingot (Co:S=90:10), and then remelting the alloy ingot to obtain an alloy with a uniform nanocrystalline two-phase structure Bands. Finally, the alloy strips were electrochemically etched using sulfuric acid aqueous solution through the three-electrode system of the electrochemical workstation, and etched at a corrosion voltage of 0.00V vs. Ag / AgCl for 1000s to obtain nanoporous cobalt sulfide strips.

[0041] Using the same doped three-electrode system as in Example 1, nanoporous cobalt sulfide was used as a working electrode, and the same parameters as in Example 1 were set to perform single-atom platinum doping on nanoporous cobalt sulfide. Different cycle times can obtain single-atom platinum-doped nanoporous cobalt sulfide catalysts with different platinum loadings, and the single-atom platinum-doped nanoporous cobalt sulfide catalysts prepared...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com