Preparation method of Co0.1Ni0.75Se/rGO composite material and application thereof

A technology of composite materials and mixed solutions, applied in catalyst activation/preparation, chemical instruments and methods, chemical/physical processes, etc., can solve the problem of reduced electrocatalytic hydrogen evolution performance of catalysts, low hydrogen evolution activity and chemical stability, and complicated catalyst preparation process etc. to achieve excellent electrocatalytic hydrogen evolution performance, improved conductivity and electrochemical active area, and easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

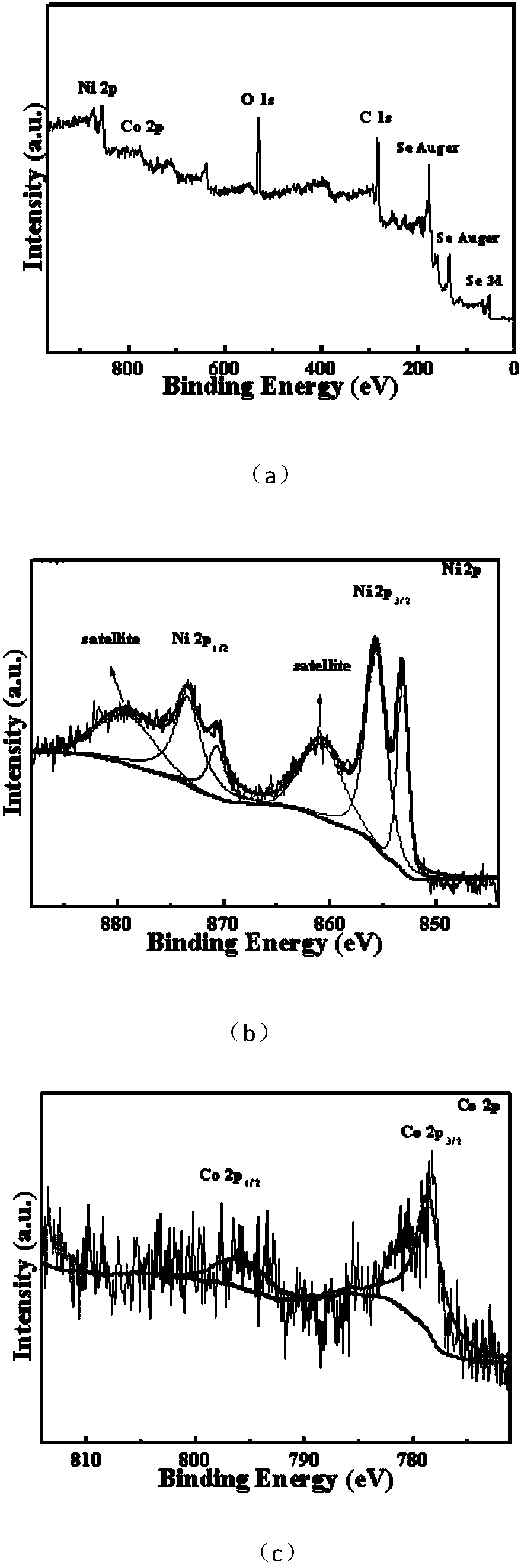

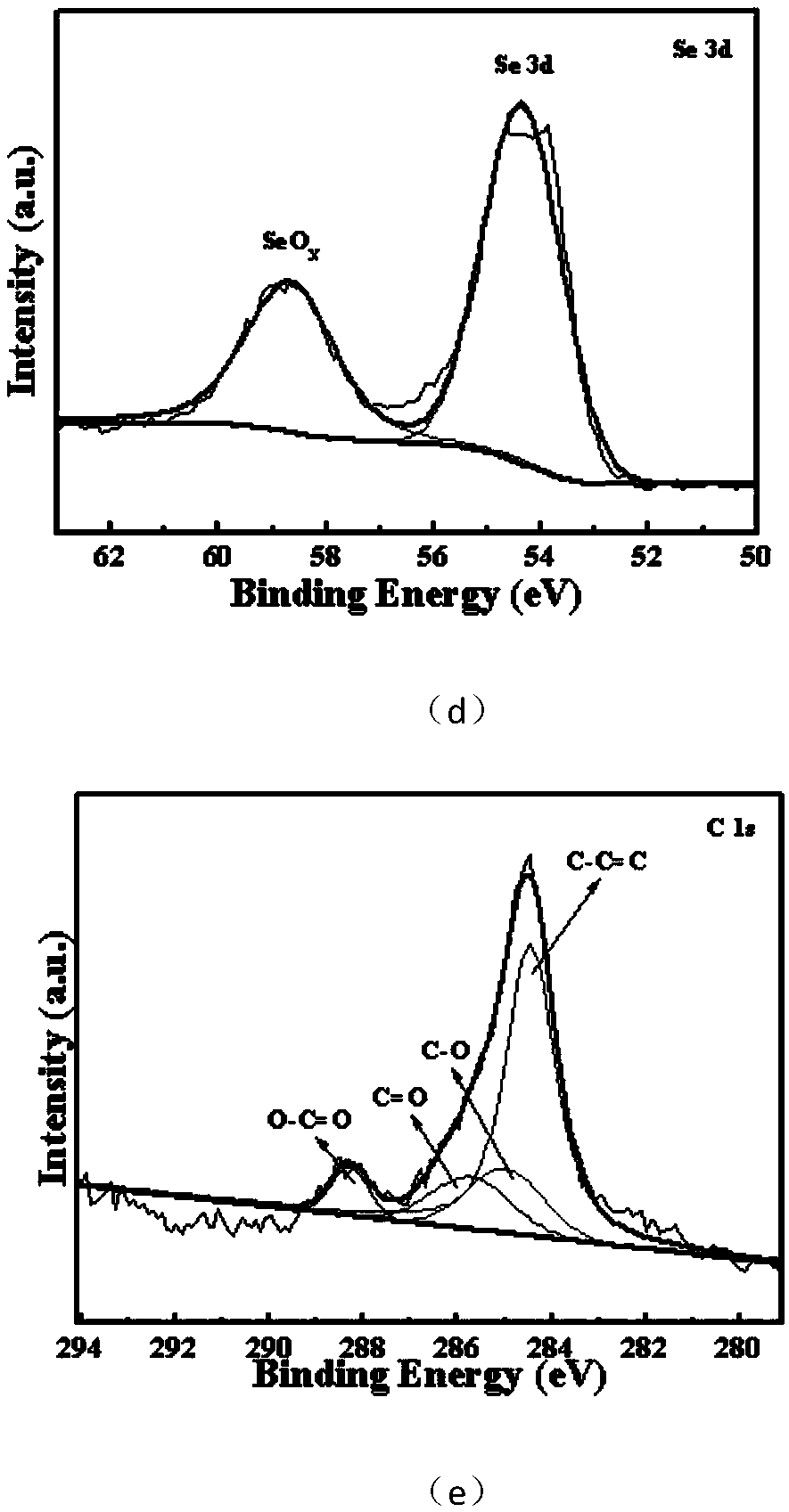

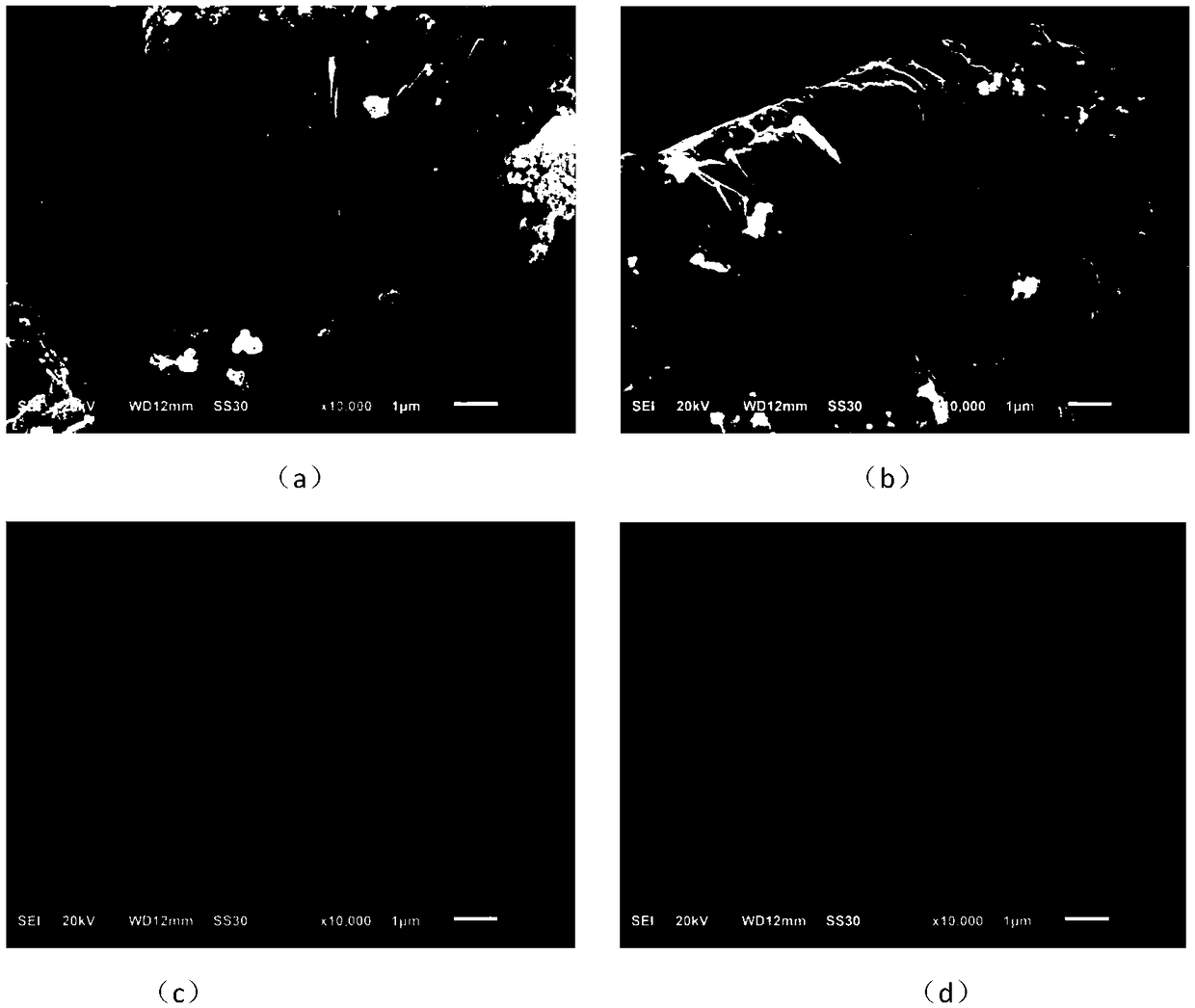

[0031] Embodiment 1 (Co 0.1 Ni 0.75 Preparation of Se / rGO composites)

[0032] (1) Disperse 17mg of graphene oxide (GO) in 10mL of deionized water, and ultrasonically disperse it into a uniform dispersion A;

[0033] (2) 0.238g (1mmol) nickel chloride hexahydrate (NiCl 2 ·6H 2O) and 0.039g (0.1mmol) of cobalt nitrate hexahydrate (Co(NO 3 ) 2 ·6H 2 O) added to 6mL deionized water successively, after magnetic stirring until uniformly dissolved, then added 0.845g (5mmol) sodium selenite (Na 2 SeO 3 ), and 24mL ethanolamine and 8.5mL hydrazine hydrate (N 2 h 4 ·H 2 O) slowly add wherein successively, continue to stir to make it form homogeneous mixed solution B;

[0034] (3) Slowly add the dispersion A prepared in step (1) to the mixed solution B prepared in step (2), stir evenly and pour it into a 100mL Teflon (polytetrafluoroethylene) lined reactor. The reaction was carried out at 140°C in an air-drying oven for 24 hours. The product obtained was washed with water an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com