Cobalt (II) metal organic framework material and application thereof in electrocatalytic hydrogen evolution

A metal-organic framework, cobalt chloride hexahydrate technology, applied in the synthesis and application of new catalyst materials, can solve the problems of large Tafel slope and high overpotential, achieve simple preparation method, reduce catalyst cost, easy separation and wash clean effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

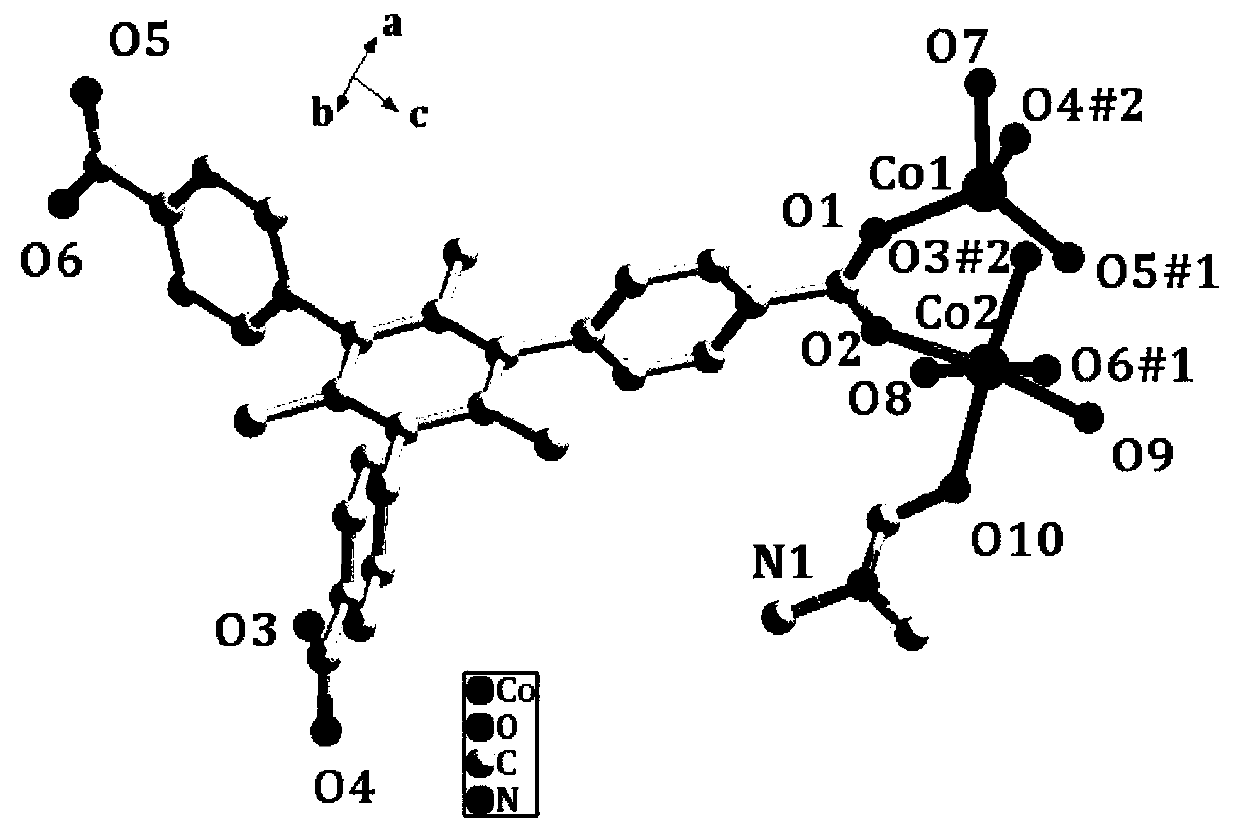

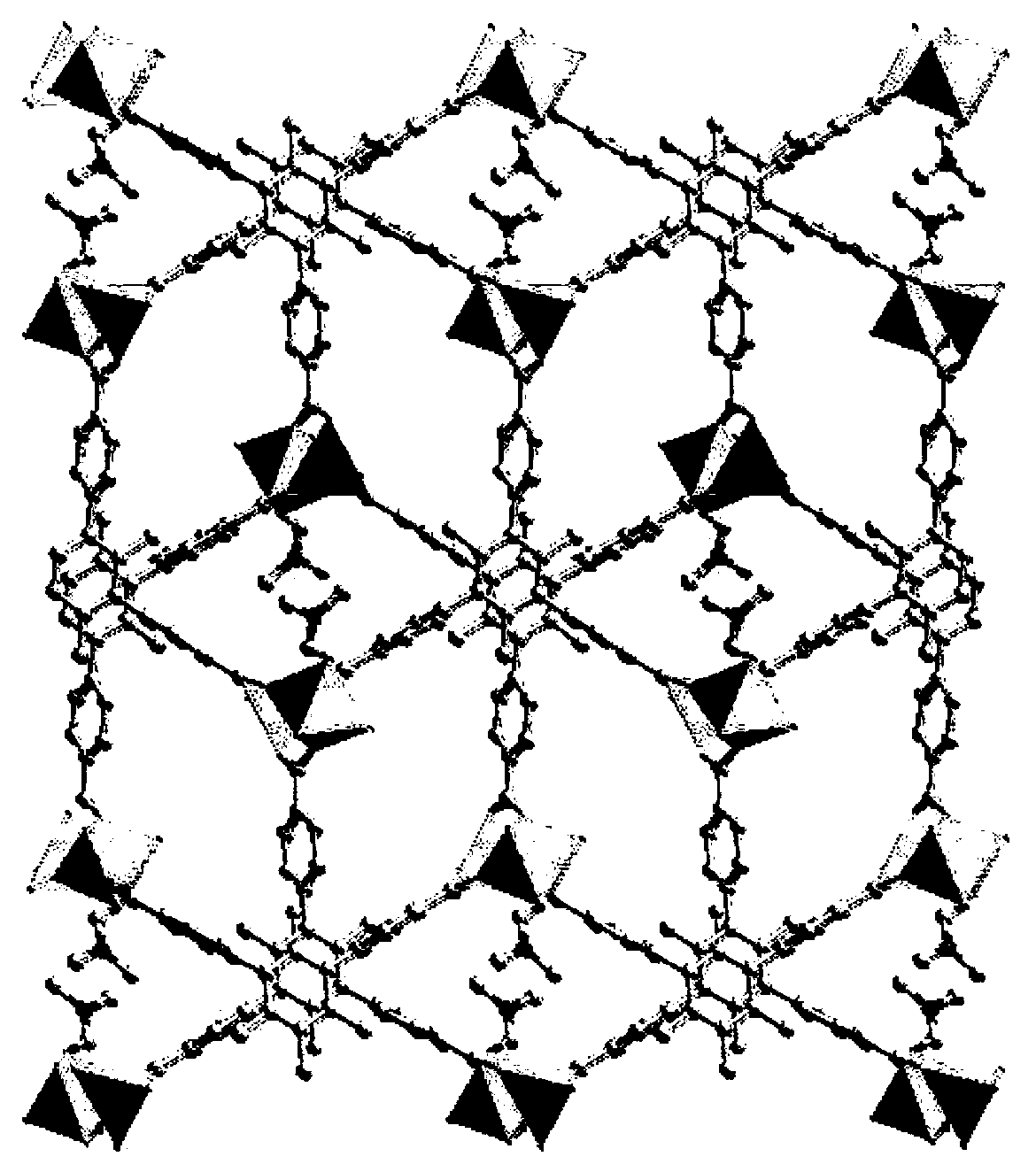

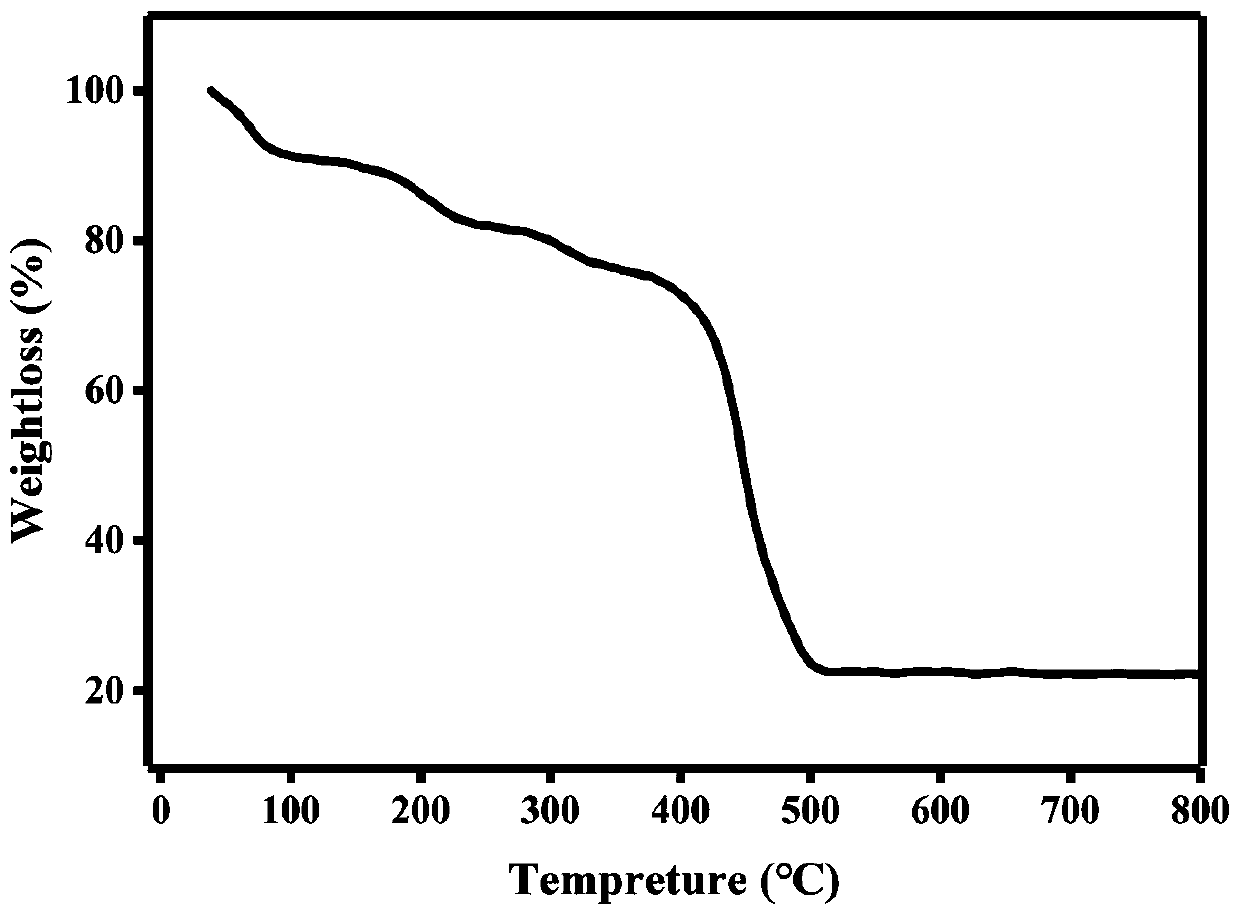

[0030] Take 9.6 mg of 1,3,5-trimethyl-2,4,6-tris(4-carboxyphenyl)benzene, 4.7 mg of cobalt chloride hexahydrate, and N,N-dimethylformamide (3 mL) , deionized water (1 mL) were mixed together in a beaker, and then 50 μL of HBF was added dropwise to the mixed solution 4 aqueous solution ( V HBF4 : V H2O = 1:3), the mixed solution was continued to be ultrasonically sonicated for 30 minutes, and finally the mixed solution was transferred to a stainless steel reactor with a polytetrafluoroethylene liner. The reaction kettle was placed in an oven at 80 °C for 24 hours at a constant temperature, and then the oven was lowered to room temperature for 10 hours to obtain a blue transparent block crystal, that is, the Co-MOF material. Depend on Figure 1-2 It can be seen that metal cobalt ions adopt two coordination configurations of four coordination and six coordination in this material, and the whole structure belongs to a two-dimensional planar structure. Depend on image 3 It ...

Embodiment 2

[0032] Take 9.6 mg of 1,3,5-trimethyl-2,4,6-tris(4-carboxyphenyl)benzene, 4.7 mg of cobalt chloride hexahydrate, and N,N-dimethylformamide (3 mL) , deionized water (1 mL) were mixed together in a beaker, and then 50 μL of HBF was added dropwise to the mixed solution 4 aqueous solution ( V HBF4 : V H2O= 1:3), the mixed solution was continued to be ultrasonically sonicated for 30 minutes, and finally the mixed solution was transferred to a stainless steel reactor with a polytetrafluoroethylene liner. The reaction kettle was placed in an oven at 100 °C for 24 hours at a constant temperature, and then the oven was lowered to room temperature for 10 hours to obtain a blue transparent bulk crystal, that is, the Co-MOF material. The powder diffraction peaks of the samples prepared in this example coincide with the XRD diffraction peaks of Example 1, and the obtained samples are Co-MOF materials with relatively high purity.

Embodiment 3

[0034] Take 9.6 mg of 1,3,5-trimethyl-2,4,6-tris(4-carboxyphenyl)benzene, 4.7 mg of cobalt chloride hexahydrate, and N,N-dimethylformamide (3 mL) , deionized water (1mL) were mixed together in a beaker, and then 50 μL of HBF was added dropwise to the mixed solution 4 aqueous solution ( V HBF4 : V H2O = 1:3), the mixed solution was continued to be ultrasonically sonicated for 30 minutes, and finally the mixed solution was transferred to a stainless steel reactor with a polytetrafluoroethylene liner. The reaction kettle was placed in an oven at 120 °C for 24 hours at a constant temperature, and then the oven was lowered to room temperature for 10 hours to obtain a blue transparent block crystal, that is, the Co-MOF material. The powder diffraction peaks of the samples prepared in this example coincide with the XRD diffraction peaks of Example 1, and the obtained samples are Co-MOF materials with relatively high purity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com