Gas sensor device, preparation method thereof and application

A gas sensor and gas-sensitive technology, applied in the field of gas sensing and sensing, can solve the problem of low sensitivity and achieve the effect of high-sensitivity sensing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) On a silicon wafer with a thermally oxidized silicon dioxide film on the surface (the thickness of the silicon dioxide layer is 100-500nm), using a chemical vapor deposition method at 800-1100°C, using methane and hydrogen as reaction gases, Use argon as the carrier gas and deposit for 20 minutes to prepare graphene films with nanocrystalline structures;

[0036] (2) By spin-coating the nanocrystalline graphene film produced in step (1), 100-800nm thick electron beam sensitive photoresist is spin-coated, and the photoresist is removed by baking at 180°C for 60 seconds. Solvent, and then through electron beam direct writing, combined with oxygen plasma etching method, cut out a 5μm×5μm area on the continuous nanocrystalline graphene film to form graphene islands (that is, the gas-sensitive center section);

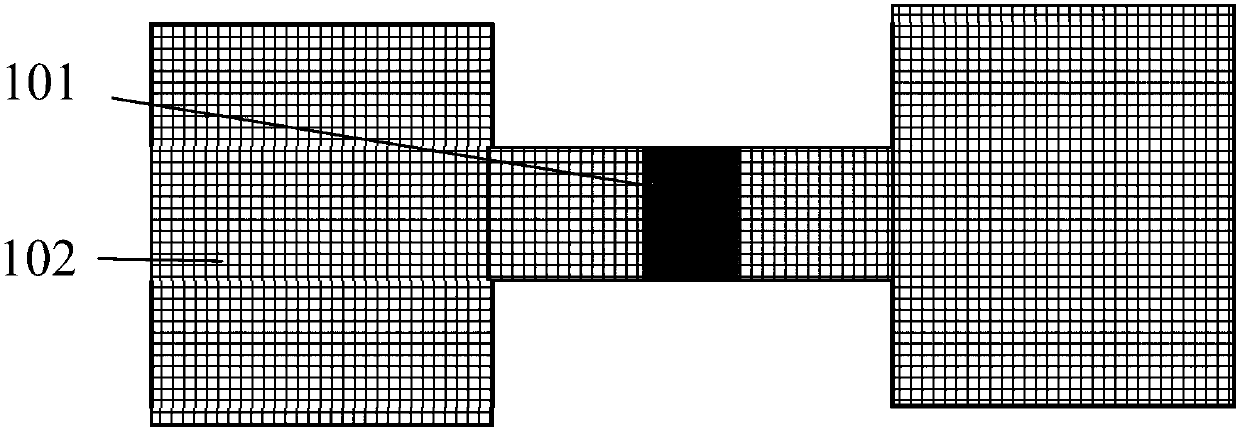

[0037] (3) The electrode is prepared by metal evaporation method (i.e. Figure 1a The grid area is shown): Coating photoresist (polymethyl methacrylate, PMMA) with ...

Embodiment 2

[0047] (1) On a silicon wafer with a thermally oxidized silicon dioxide film on the surface (the thickness of the silicon dioxide layer is 100-500nm), using a chemical vapor deposition method at 800-1100°C, using methane and hydrogen as reaction gases, Use argon as the carrier gas and deposit for 20 minutes to prepare graphene films with nanocrystalline structures;

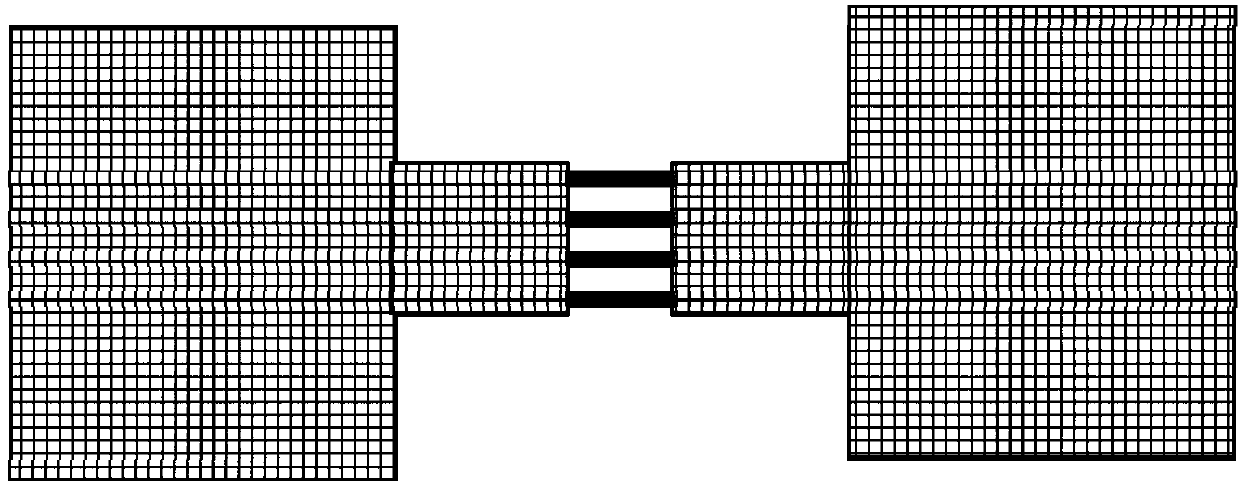

[0048] (2) By spin-coating the nanocrystalline graphene film produced in step (1), 100-800nm thick electron beam sensitive photoresist is spin-coated, and the photoresist is removed by baking at 180°C for 60 seconds. Solvent, and then through electron beam direct writing, combined with oxygen plasma etching method, cut out a 5μm×5μm area on the continuous nanocrystalline graphene film to form graphene islands (that is, the gas-sensitive center Part), and then cut the graphene island into mutually parallel strips, the width of the strip is 1 μm, and the distance between the two strips is 1 μm;

[0049] (3) The electr...

Embodiment 3

[0056] (1) On a silicon wafer with a thermally oxidized silicon dioxide film on the surface (the thickness of the silicon dioxide layer is 100-500nm), using a chemical vapor deposition method at 800-1100°C, using methane and hydrogen as reaction gases, Use argon as the carrier gas and deposit for 20 minutes to prepare graphene films with nanocrystalline structures;

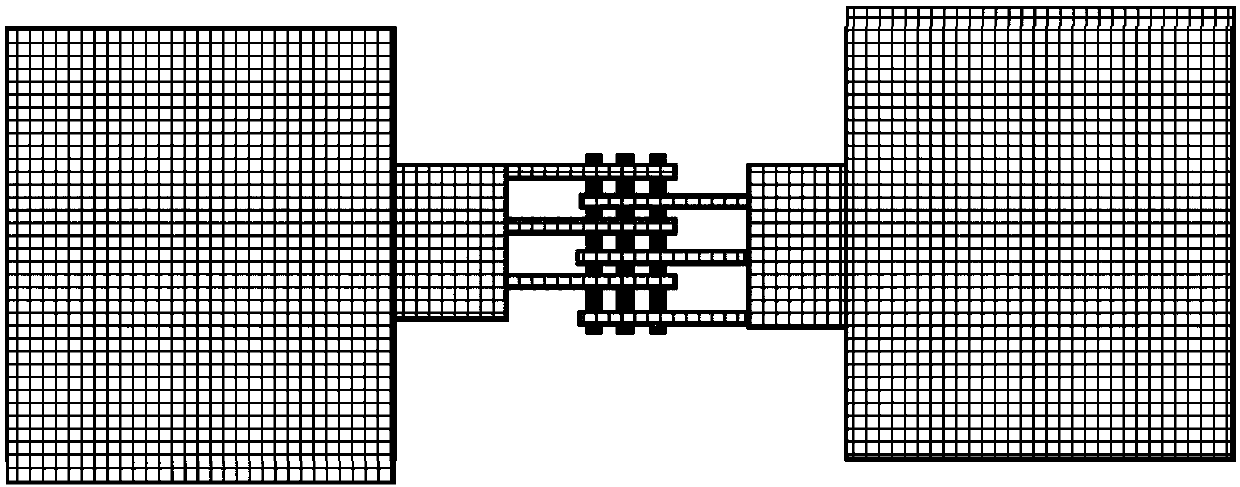

[0057] (2) By spin-coating the nanocrystalline graphene film produced in step (1), 100-800nm thick electron beam sensitive photoresist is spin-coated, and the photoresist is removed by baking at 180°C for 60 seconds. Solvent, and then through electron beam direct writing, combined with oxygen plasma etching method, cut out a 5μm×5μm area on the continuous nanocrystalline graphene film to form graphene islands (that is, the gas-sensitive center Part), and then cut the graphene island into mutually parallel strips, the width of the strip is 1 μm, and the distance between the two strips is 1 μm;

[0058] (3) The electr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com