NO2 sensor and preparation method thereof

A sensing method and sensor technology, applied in the sensing field, can solve the problems of limited practical application, energy waste, low detection limit, etc., and achieve the effects of simple operation, good selectivity and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

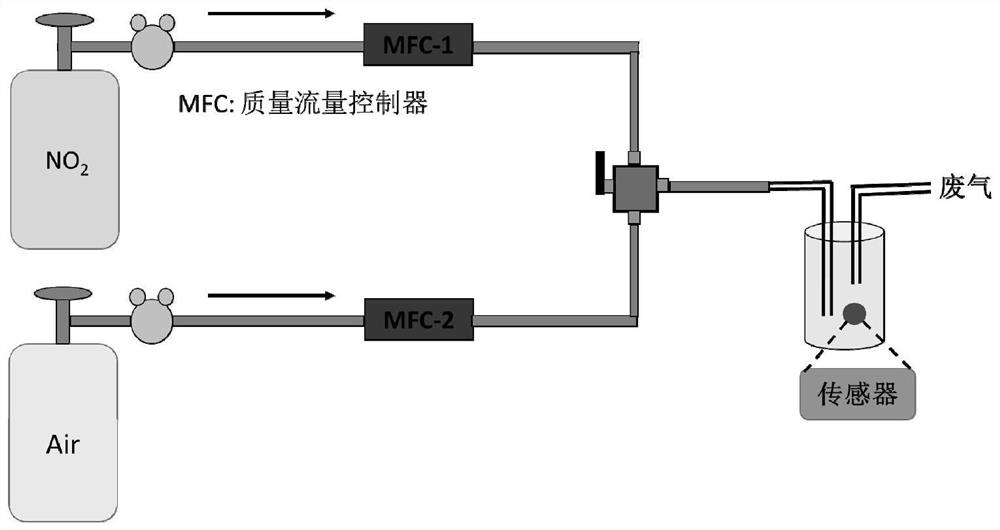

[0024] (1) Preparation of the sensor: the Ni / Co double metal oxide was prepared into a suspension with absolute ethanol, and dispersed uniformly by ultrasonic. Use a pipette gun to pipette an appropriate amount and evenly coat the surface of the ceramic tube to form a thin film. After thorough drying, fix the coated ceramic tube in a self-made sealed bottle with a wire, and check the tightness of the entire gas circuit.

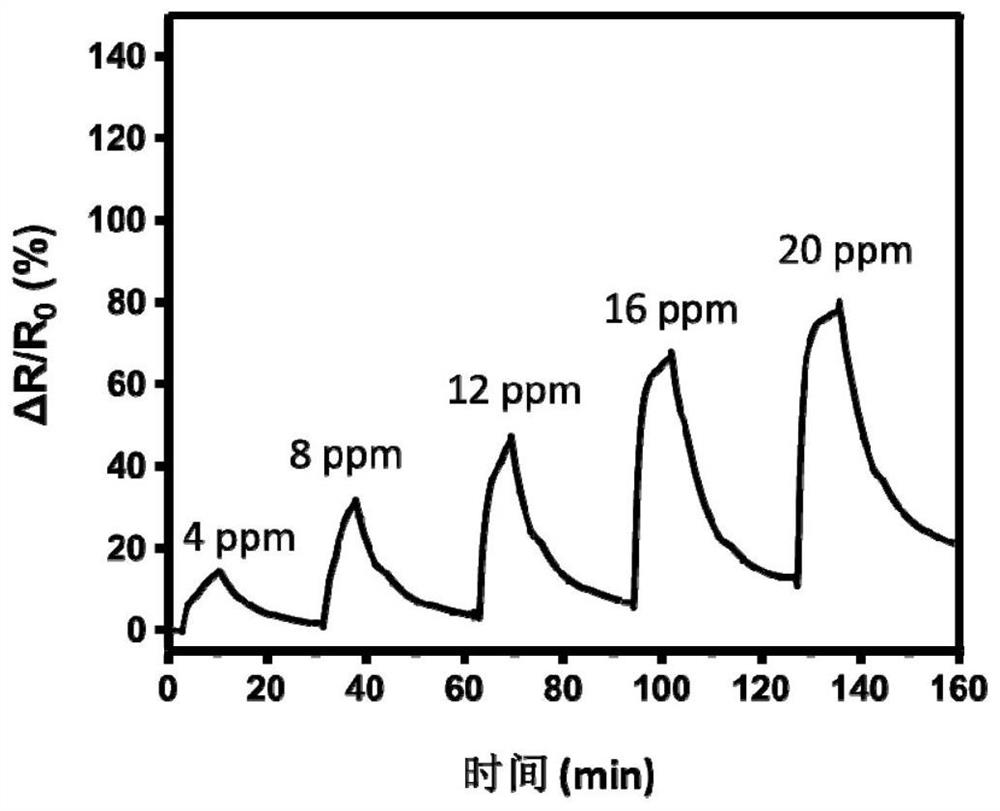

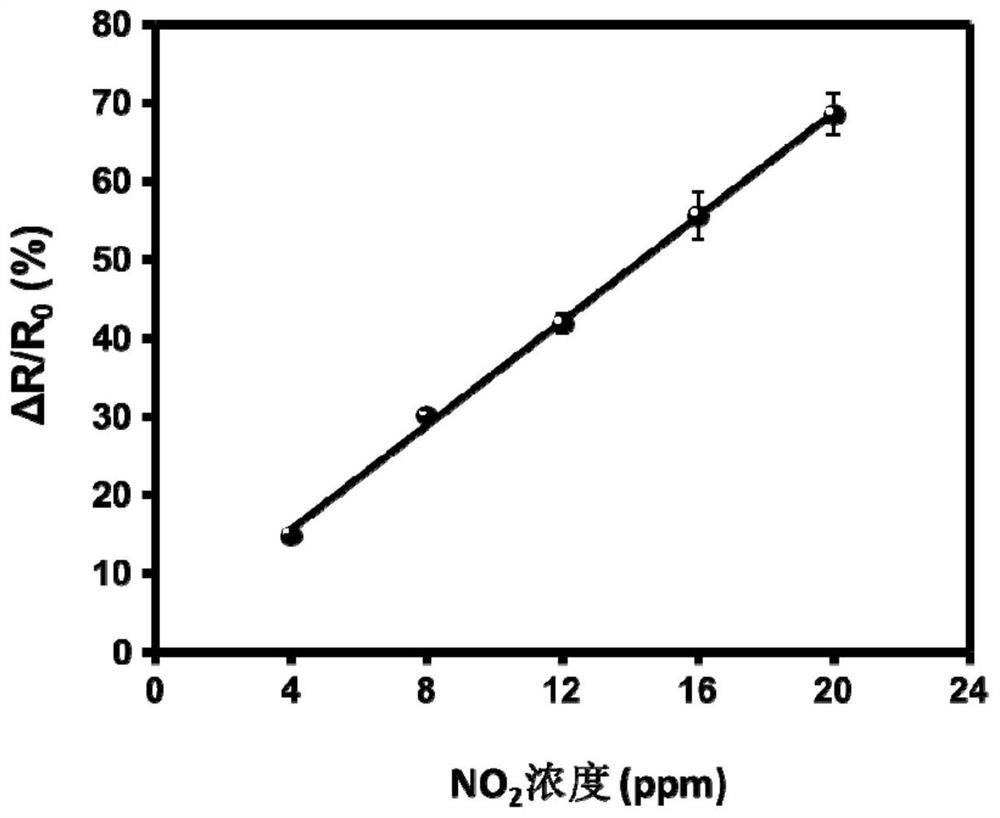

[0025] (2)NO 2 Sensing: Use an external DC power supply to heat the sensor to a specific temperature. Open a certain flow of air through the flow control system, and make the resistance of the sensor reach a stable value in dry air. Under the premise of keeping the total flow constant, adjust the NO 2 with air flow to achieve a change in NO 2 concentration effect. Start the timer to make different concentrations of NO 2 After reacting with the sensor for a certain period of time, turn off the NO 2 Air circuit, adjust the flow rate of the air circuit to...

Embodiment 1

[0034] The preparation of embodiment 1 sensor

[0035] The Ni / Co double metal oxide was formulated into a 1 mg / ml suspension with absolute ethanol, and dispersed evenly by ultrasonication for 30 minutes. Pipette an appropriate amount of 20 μL and evenly coat the surface of the ceramic tube to form a 0.2 mm thin film. After being thoroughly dried at room temperature for 12 hours, the coated ceramic tube was fixed in a self-made sealed bottle with wires, such as figure 1 As shown, one end of the two wires is connected to the metal post of the sensor base, and the other end is connected to the multimeter. One end of the other two wires is also connected to the metal post of the sensor base, and the other end is connected to the DC power supply. Air tightness.

Embodiment 2

[0036] The preparation of embodiment 2 sensor

[0037]The Ni / Co double metal oxide was formulated into a 1 mg / ml suspension with absolute ethanol, and dispersed evenly by ultrasonication for 30 minutes. Pipette an appropriate amount of 50 μL and evenly coat the surface of the ceramic tube to form a 0.5 mm thin film. After being thoroughly dried at room temperature for 12 hours, the coated ceramic tube was fixed in a self-made sealed bottle with wires, such as figure 1 As shown, one end of the two wires is connected to the metal post of the sensor base, and the other end is connected to the multimeter. One end of the other two wires is also connected to the metal post of the sensor base, and the other end is connected to the DC power supply. Air tightness.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com