Antibacterial composite leather material and preparation method thereof

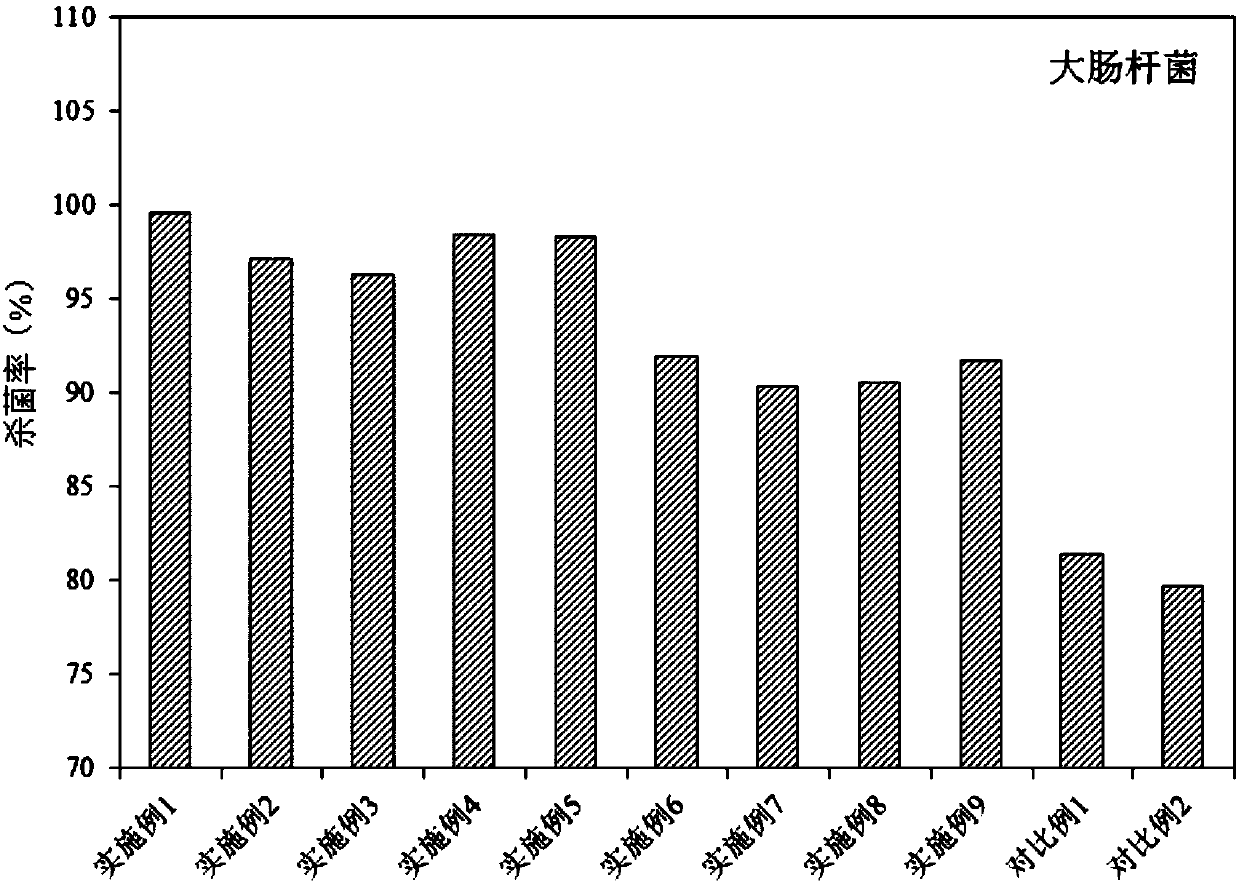

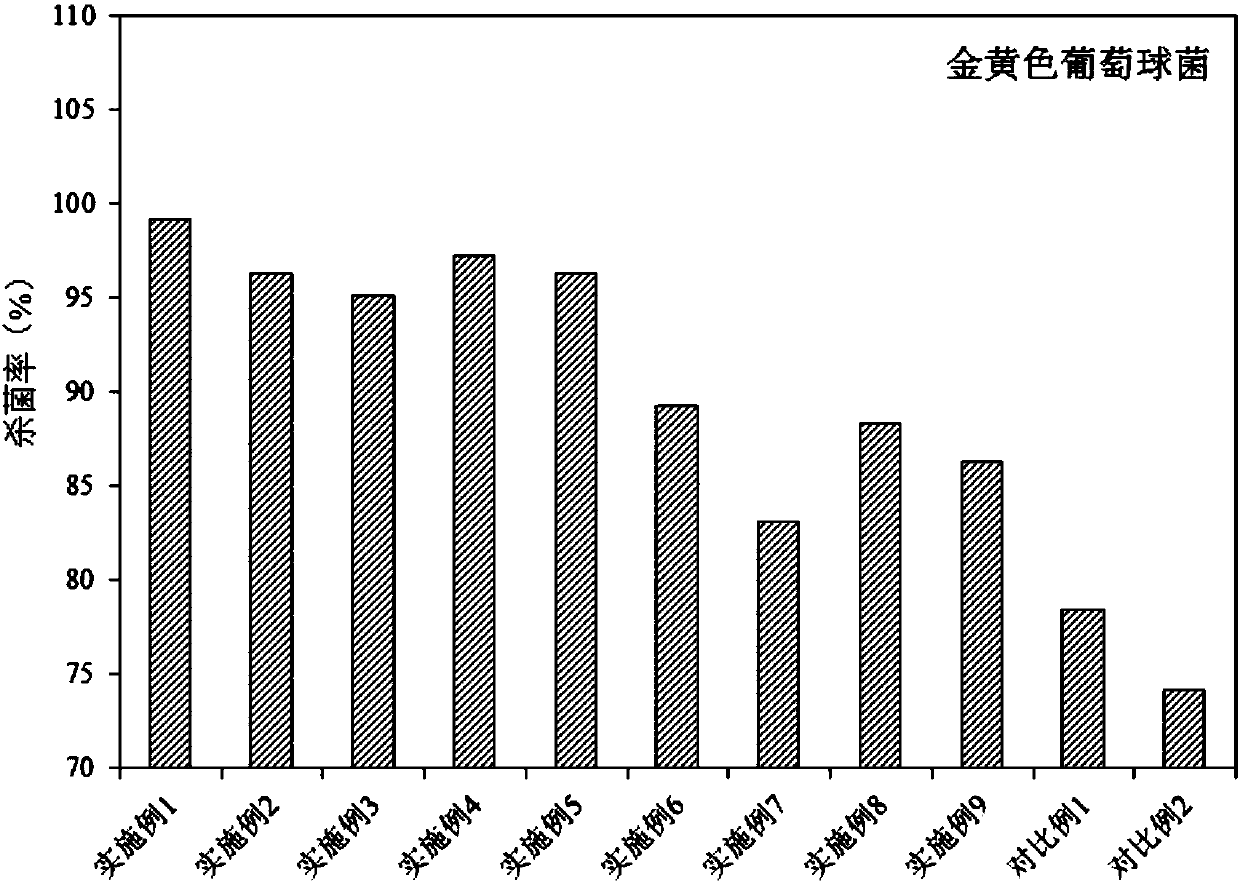

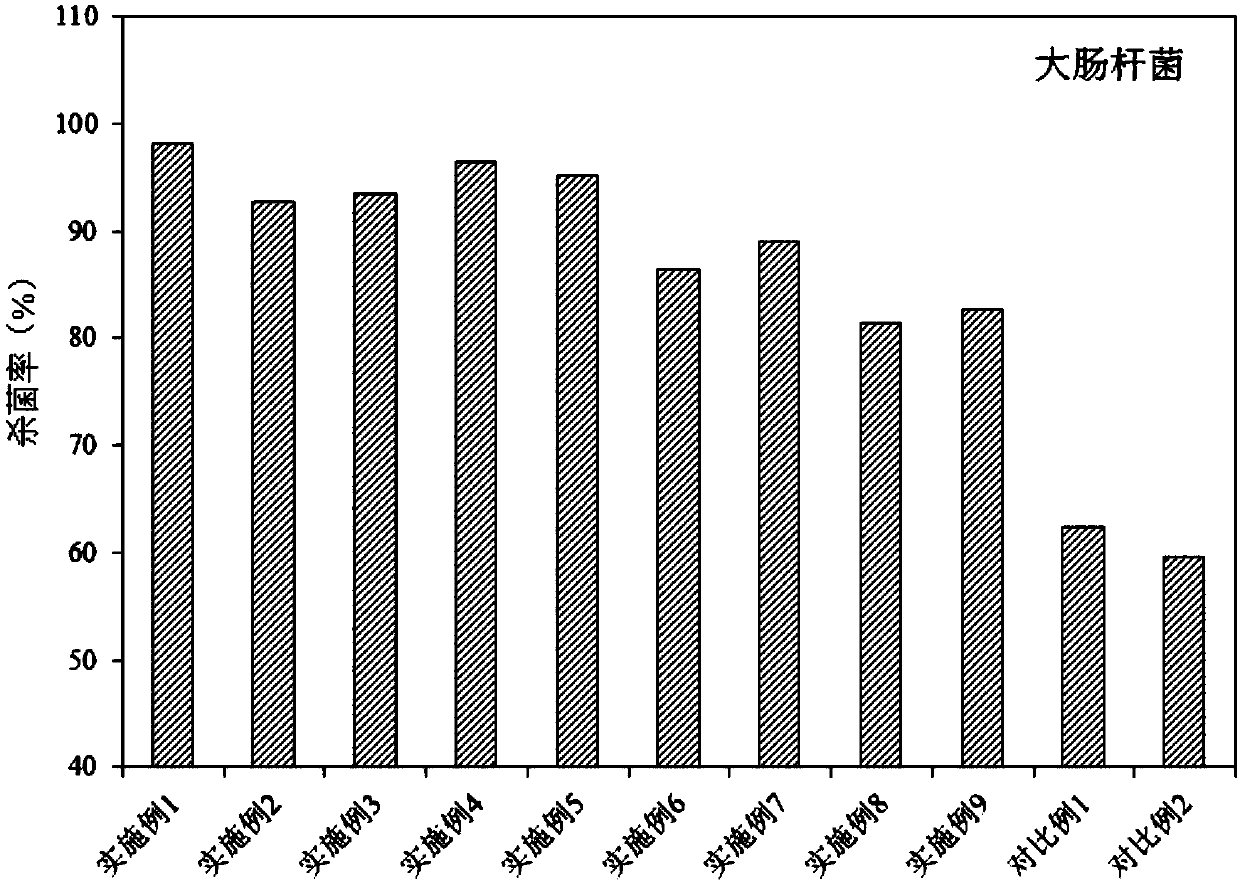

A technology for leather and leather fibers, applied in the field of antibacterial composite leather materials and their preparation, can solve the problems that medical supplies are tasteless, clean, hygienic, antibacterial, have no antibacterial function, residual bacteria in leather, etc., and achieve no allergic side effects, Efficient bactericidal performance, strong antibacterial lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] A kind of preparation method of antibacterial composite leather material provided by the invention comprises the following steps:

[0029] In parts by weight, mix 80-130 parts of modified leather fiber, 8-20 parts of resin, 1-5 parts of plasticizer, 2-4 parts of heat stabilizer, and 2-6 parts of polar wax at a temperature of 80-110°C , mixing under the condition of rotating speed 800~1500r / min for 5~10 minutes, then press molding under the pressure of 150~200MPa to obtain the rough leather material, smear 1~5 parts of stearic acid on the surface of the described rough leather material, After standing at room temperature for 1 to 2 hours, put it at a temperature of 90 to 110°C and a roller pressure of 4 to 6Kg / cm 3 rolling into an antibacterial composite leather material under conditions; wherein, the modified leather fiber is compounded by chitosan, titanium dioxide, and leather fiber in the presence of a crosslinking agent, and the chitosan and the leather fiber The w...

Embodiment 1

[0058] The embodiment of the present invention provides a kind of preparation method of antibacterial composite leather material, comprises the following steps:

[0059] (1) Preparation of leather fiber:

[0060] Put the cowhide in a pulverizer and crush it into a particle size of 12mm×12mm, then put it in hydrogen peroxide (its pH value is 6.5), and soak it at 70°C for 3 hours so that the cowhide is fully oxidized and decomposed to obtain the pretreated cowhide. The treated cowhide is crushed and ground to obtain fiber slurry, put the obtained slurry into clear water, statically stratify, filter to remove impurities, and obtain filter residue, put the obtained filter residue in an oven, control the temperature at 70°C, and the time is 40min , to obtain dry leather fibers.

[0061] (2) Modification of leather fiber:

[0062] According to the volume ratio of tetrabutyl titanate, deionized water, absolute ethanol and concentrated hydrochloric acid as 1:250:15:1.5, mix deionize...

Embodiment 2

[0068] The embodiment of the present invention provides a kind of preparation method of antibacterial composite leather material, comprises the following steps:

[0069] (1) Preparation of leather fiber:

[0070] Put the cowhide in a pulverizer to crush it into a particle size of 12mm×12mm, then place it in hydrogen peroxide (its pH value is 6), soak it at 60°C for 4 hours to fully oxidize and decompose the cowhide, and obtain the pretreated cowhide. The pretreated cowhide is crushed and ground to obtain fiber slurry, which is put into clear water, statically layered, filtered to remove impurities, and the filter residue is obtained. The obtained filter residue is placed in an oven, and the temperature is controlled at 60 ° C. The time is 30min to obtain dry leather fibers.

[0071] (2) Modification of leather fiber:

[0072] According to the volume ratio of tetrabutyl titanate, deionized water, absolute ethanol and concentrated hydrochloric acid as 0.5:100:10:0.5, mix deion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com