Preparation and application of a kind of silicon-containing dendritic-linear fatliquoring agent

A technology of dendritic and fatliquor, which is applied in the preparation and application field of silicon-containing dendritic-linear fatliquor, can solve the problem of single function, and achieve the effect of simple synthesis method, high biocompatibility and low pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

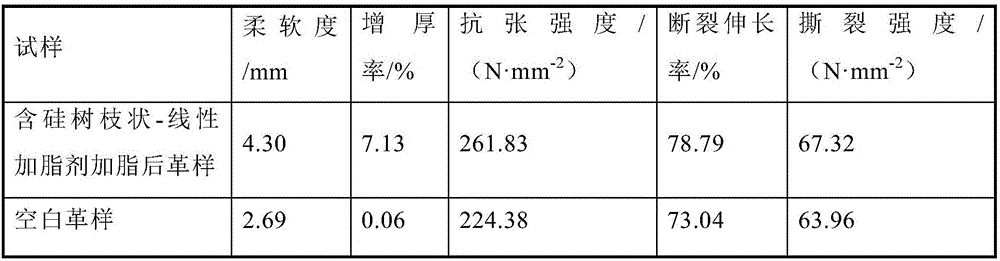

Examples

Embodiment 1

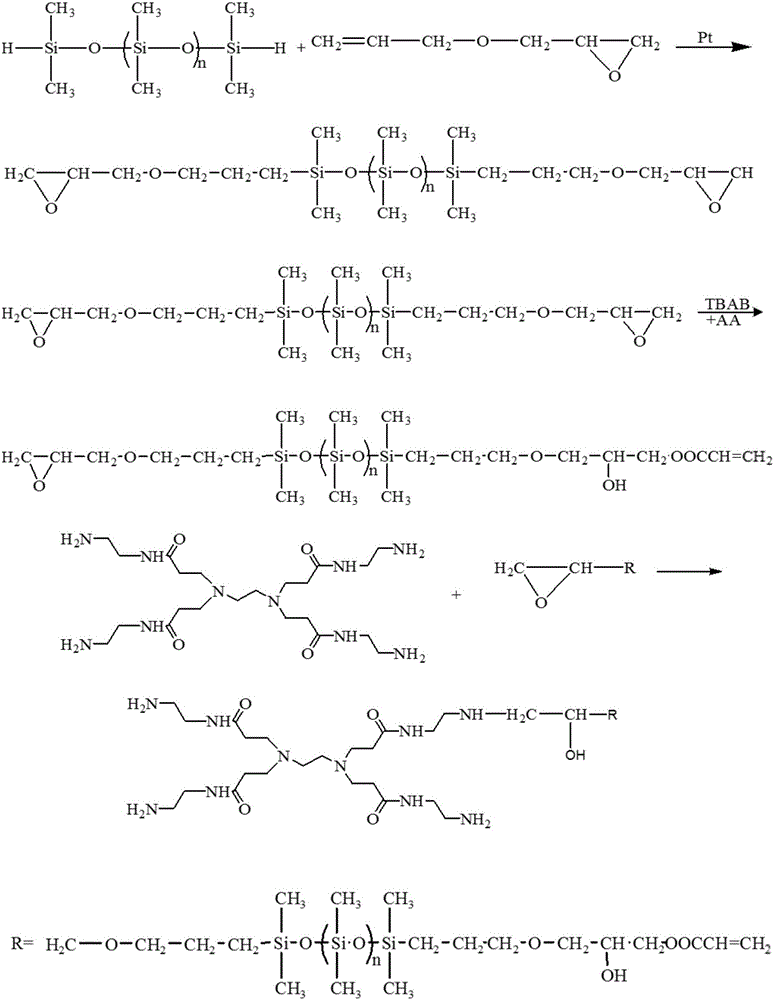

[0020] A preparation method of silicon-containing dendritic-linear fatliquoring agent, comprising the following steps:

[0021] Step 1: Add terminal hydrogen-containing polysiloxane and allyl glycidyl ether with a molar ratio of 1:2.1 to the reaction vessel, and add 0.15% catalyst chloroplatinic acid and excess solvent toluene to the total mass of the reactants, and mix well Afterwards, the temperature was raised to 90° C. for reflux reaction for 4 hours, and the reaction solvent toluene and excess allyl glycidyl ether were removed by vacuum filtration at 70-90° C. to obtain epoxy-terminated polysiloxane.

[0022] Step 2: Add the double-ended epoxy polysiloxane synthesized above, acrylic acid and solvent toluene into the reaction vessel at a molar ratio of 1:1.1, add the solvent toluene and tetrabutylammonium bromide accounting for 0.6% of the total mass of the reactants Catalyst, the above reaction system was refluxed at 100°C for 6 hours, and then the solvent toluene was rem...

Embodiment 2

[0026] A preparation method of silicon-containing dendritic-linear fatliquoring agent, comprising the following steps:

[0027] Step 1: Add terminal hydrogen-containing polysiloxane and allyl glycidyl ether with a molar ratio of 1:2.3 to the reaction vessel, and add 0.2% catalyst chloroplatinic acid and excess solvent toluene to the total mass of the reactants, and mix well Afterwards, the temperature was raised to 90° C. for reflux reaction for 6 hours, and the reaction solvent toluene and excess allyl glycidyl ether were removed by vacuum filtration at 70-90° C. to obtain epoxy-terminated polysiloxane.

[0028] Step 2: Add the double-ended epoxy polysiloxane synthesized above, acrylic acid and solvent toluene into the reaction vessel at a molar ratio of 1:1.1, add the solvent toluene and tetrabutylammonium bromide accounting for 0.6% of the total mass of the reactants Catalyst, the above reaction system was refluxed at 100°C for 6 hours, and then the solvent toluene was remo...

Embodiment 3

[0032] A preparation method of silicon-containing dendritic-linear fatliquoring agent, comprising the following steps:

[0033] Step 1: Add terminal hydrogen-containing polysiloxane and allyl glycidyl ether with a molar ratio of 1:2.3 to the reaction vessel, and add 0.2% catalyst chloroplatinic acid and excess solvent toluene to the total mass of the reactants, and mix well Afterwards, the temperature was raised to 90° C. for reflux reaction for 6 hours, and the reaction solvent toluene and excess allyl glycidyl ether were removed by vacuum filtration at 70-90° C. to obtain epoxy-terminated polysiloxane.

[0034] Step 2: Add the double-ended epoxy polysiloxane synthesized above, acrylic acid and solvent toluene into the reaction vessel at a molar ratio of 1:1.3, add the solvent toluene and tetrabutylammonium bromide accounting for 0.65% of the total mass of the reactants Catalyst, the above reaction system was refluxed at 120°C for 8 hours, and then the solvent toluene was rem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com