Diamond-like thin film solar cell and manufacturing method thereof

A diamond thin film and solar cell technology, applied in the field of solar cells, can solve the problems of current loss and low conversion efficiency, and achieve the effects of avoiding current loss, high photoelectric conversion efficiency, and optimizing spectral response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

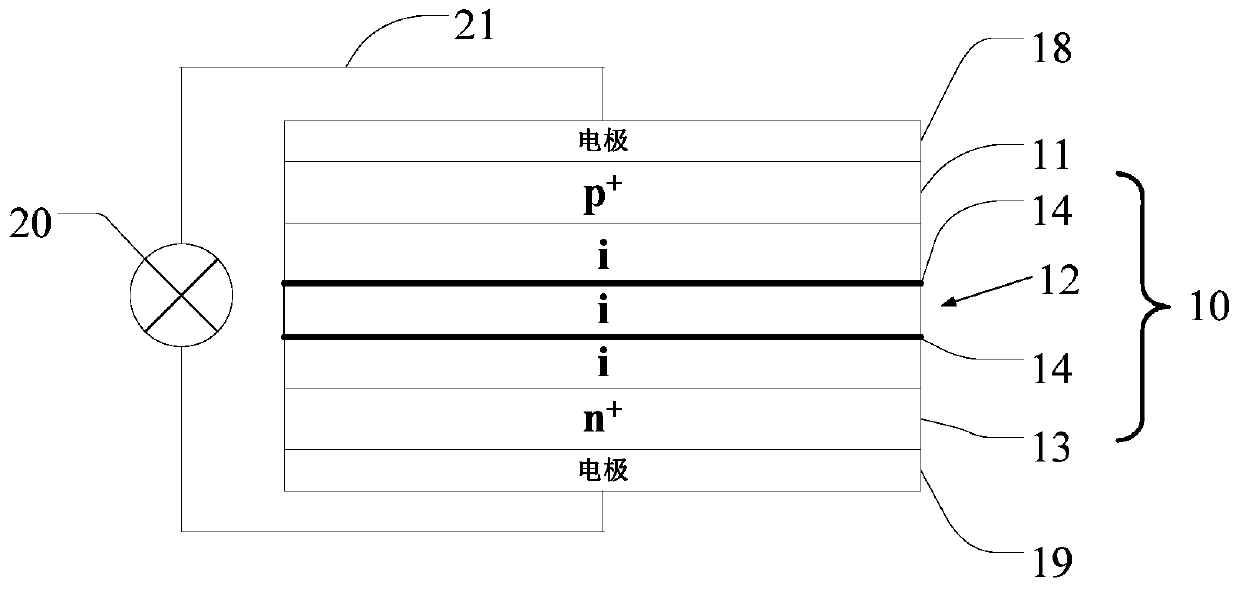

[0030] now refer to figure 1 , figure 1 is a schematic diagram of a thin film solar cell, according to one embodiment of the present invention, having a pin junction 10 comprising a p+ type layer 11, an n+ type layer 13 and a plurality of successively stacked intrinsic layers 12. The battery also includes an electrode 18 connected to one side of the p+ type layer 11 and an electrode 19 on one side of the n+ type layer 13; wherein each of the p+ type layer 11 and the n+ type layer 13 has a different sp3 / sp2 ratio.

[0031] figure 1 In the schematic diagram of the solar cell shown, there are three consecutive stacked intrinsic layers, corresponding to the solar spectrum in the three bands of ultraviolet, visible light and infrared, so as to achieve the effect of full-spectrum absorption and achieve higher photoelectric conversion efficiency of solar cells .

[0032] Each intrinsic layer 12 includes a plurality of quantum wells. The intrinsic layers 12 are connected by a tu...

Embodiment 2

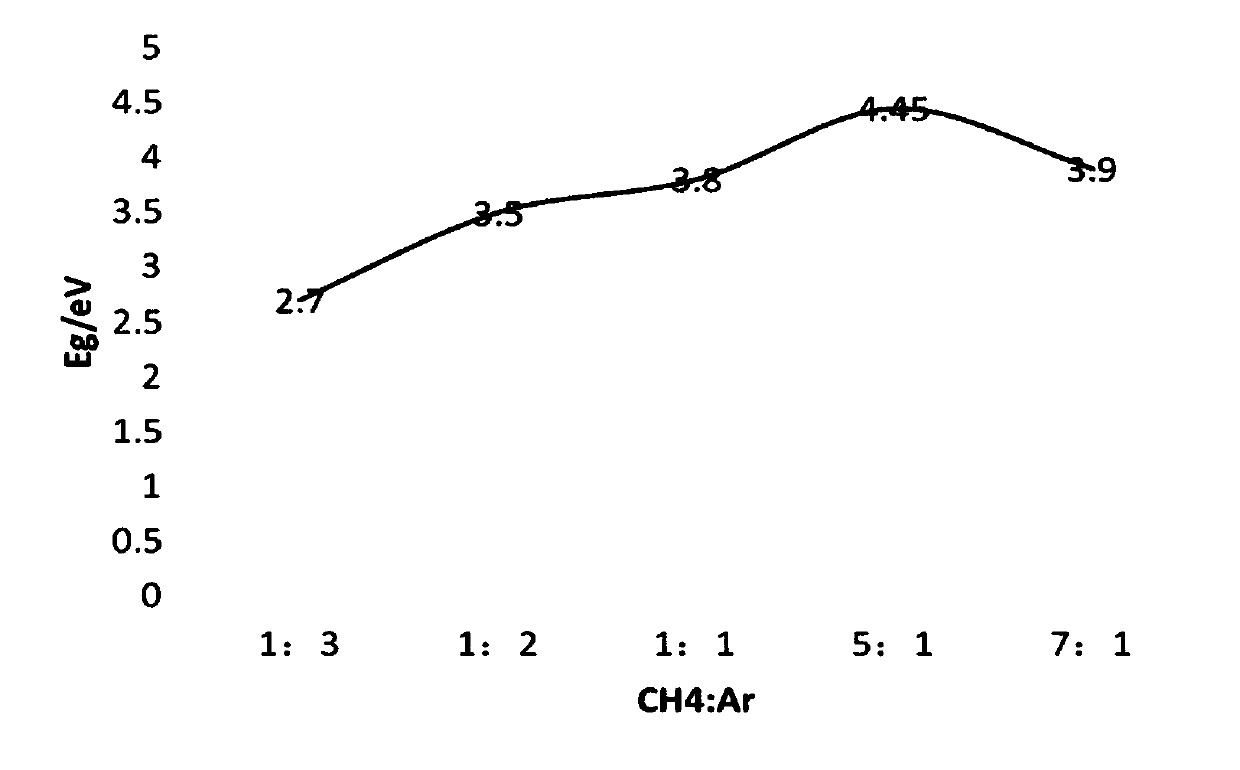

[0040] The specific structure of the diamond-like solar cell structure refers to Example 1. The diamond-like solar cell has a pin junction, and the pin junction includes a p+ type layer, an n+ type layer, and a plurality of successively stacked intrinsic layers; and, an electrode connected to one side of the p+ type layer and an electrode connected to the n+ type layer An electrode on one side of the invention; wherein, in a plurality of successively stacked intrinsic layers, each intrinsic layer has a different sp3 / sp2 ratio and a corresponding forbidden band width. The intrinsic layer is a diamond-like material, and the diamond-like material is a mixture of crystalline carbon and amorphous carbon.

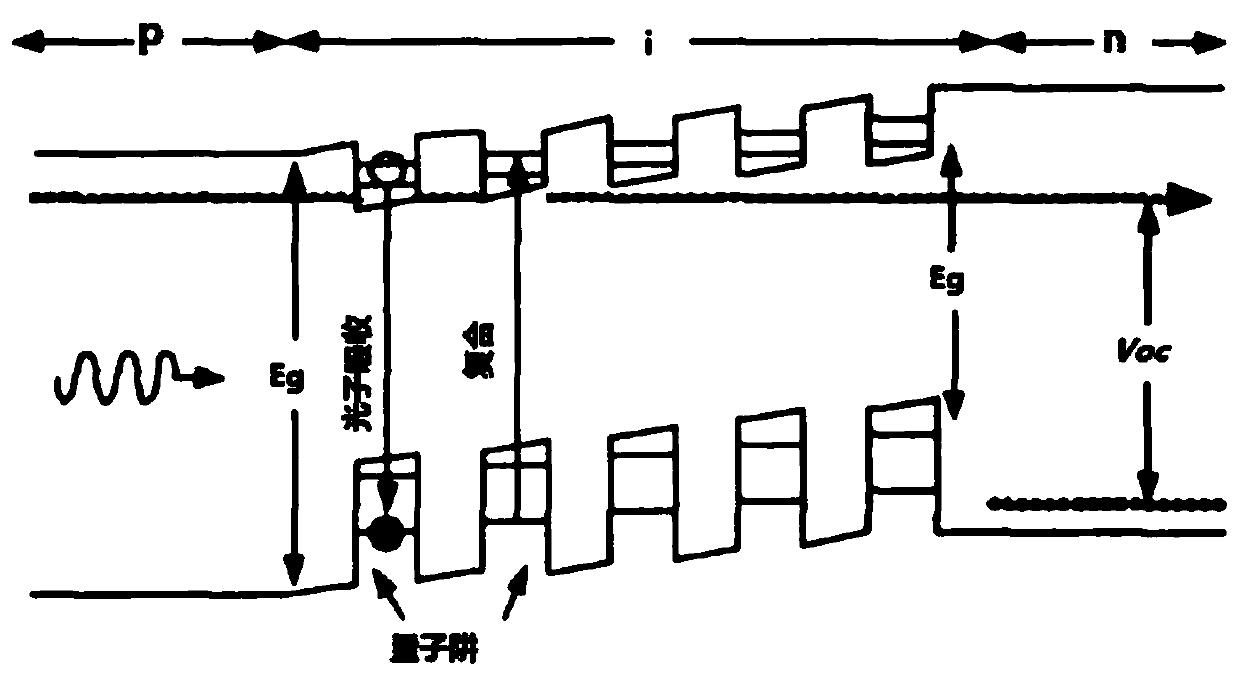

[0041] Each intrinsic layer includes one or more quantum wells. in, figure 2is a schematic diagram of the energy levels of a quantum well with a single intrinsic layer. The thickness of the quantum well is 3-10nm, which is the superposition of 15-50 carbon atom layers, so as ...

Embodiment approach

[0050] According to one embodiment of the present invention, there is provided a method for manufacturing a diamond-like thin film solar cell, comprising the following steps:

[0051] (a) A gas mixture of a hydrocarbon (such as methane) and other gases is introduced into the deposition chamber to form the first electrode layer, thereby creating a pin junction with a plurality of successively stacked intrinsic layers having p+ type layer, n+ type layer and intrinsic layer;

[0052] (b) varying the sp3 / sp2 ratio of at least each p+-type layer and n+-type layer, which may be doped to enhance electron mobility in each pin junction;

[0053] (c) manufacturing a second electrode layer according to steps a and b;

[0054] Therein, a plurality of successively stacked intrinsic layers are brought close to each other in step (a) to produce a solar cell having an optimized spectral response and an optimized thermal response to an oriented light source.

[0055] figure 2 is an energy ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com