Small-diameter pipe phased array ultrasonic detection comparison test block and detection calibration method using same

A technology for ultrasonic testing and comparison of test blocks, which is used in material analysis using sonic emission technology, solid analysis using sonic/ultrasonic/infrasonic waves, and material analysis using sonic/ultrasonic/infrasonic waves. It cannot reflect the influence of the inner and outer walls of the tubular workpiece, and the quantitative error of the small diameter tube is obvious, so as to improve the accuracy and reliability, verify the correctness and reliability, and reduce the risk of missed detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

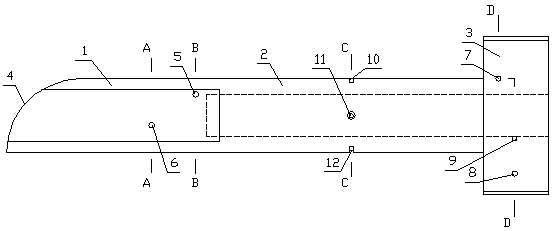

[0034] Below in conjunction with accompanying drawing, the present invention is described in further detail.

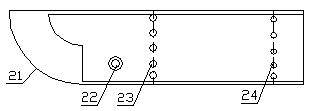

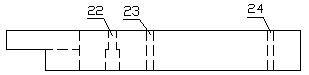

[0035] Such as Figure 3 to Figure 7 As shown, the small-diameter pipe phased array ultrasonic testing comparison test block of this embodiment includes an integrally connected middle pipe section 2 and verification sections 1 and 3 at both ends. The outer diameter and coaxial partial arc surface, the two verification sections 1 and 3 are provided with parallel side surfaces, and the end of the verification section 1 is provided with an arc surface 4 with the same radius as the outer diameter of the middle pipe section 2 , and the center of the arc surface 4 is located on the outer circular extension surface of the middle pipe section 2, two through holes 5, 6 are provided in the verification section 1, and the axis of the through hole 5 is located on the inner hole extension surface of the middle pipe section 2, The through hole 6 is axially located between the arc ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com