CPVC pipe for fire protection engineering and preparation method of CPVC pipe

A CPVC pipe and engineering technology, applied in the direction of pipes, rigid pipes, damage protection, etc., can solve problems such as differences in flame retardant and fire resistance, and achieve the effects of excellent wear resistance, excellent fire resistance and flame retardant performance, and low thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below through specific examples, but the examples do not limit the protection scope of the present invention.

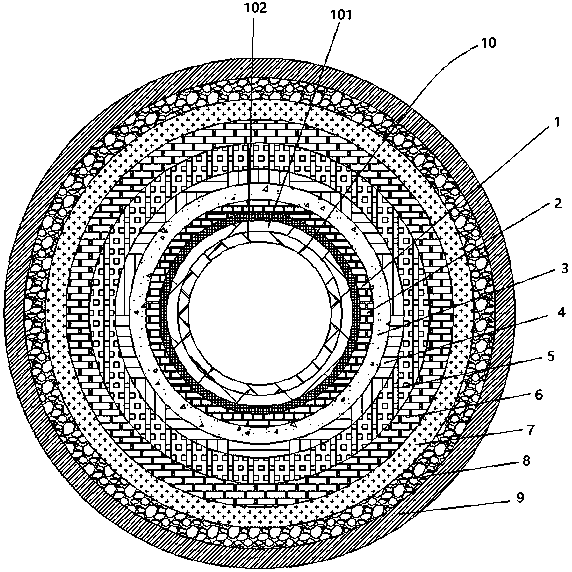

[0030] refer to figure 1 , a CPVC pipe for fire protection engineering according to the present invention, the CPVC pipe comprises: CPVC base pipe 1; epoxy powder layer 2 and adhesive layer 3 arranged on the outer wall of the CPVC base pipe 1 sequentially from inside to outside , flame retardant layer 4, heat resistant layer 5, oxygen barrier layer 6, antistatic layer 7, anticorrosion layer 8 and protective adhesive layer 9; the inner lining layer 10 arranged on the inner wall of the CPVC base pipe 1; the flame retardant coating The layer includes the following components by weight: polyurethane resin: 30~40 parts, methyl methacrylate: 25~35 parts, butyl acrylate: 10~15 parts, acrylamide: 10~15 parts, polyvinyl alcohol: 10~ 15 parts, ammonium polyphosphate: 10~15 parts, cellulose acetate: 15~25 parts, defoamer: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com