High-molecular water-absorbent resin, composite absorbent core and preparation method of water-absorbent resin

A technology for absorbent cores and water-based resins, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc. Leakage or flooding and other problems, to avoid insufficient improvement, obvious capillary effect, and promote the effect of later absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

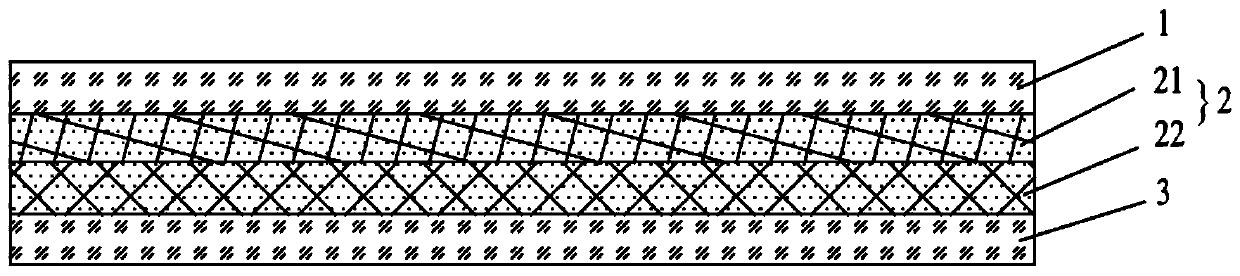

Image

Examples

preparation example Construction

[0029] In a first aspect, the present invention provides a method for preparing a polymer water-absorbent resin, the method comprising the following steps:

[0030] (1) Mix acrylic acid (water-soluble polymerizable monomer), crosslinking agent and hydrophobic polymerizable monomer composed of halogenated styrene and cycloisoprene with water to obtain a mixture;

[0031] (2) Add water-based resin dispersion and antibacterial and deodorizing additives to the mixture obtained in step (1) and pass nitrogen gas to remove oxygen (for example, pass nitrogen gas to remove oxygen for 8 to 20 minutes) to obtain a mixed solution, and then add The initiator initiates the polymerization reaction to obtain a resin gel;

[0032] (3) The resin gel obtained in step (2) is successively granulated, neutralized, dried (for example, the drying temperature can be 140° C.), ground and sieved to obtain a polymer water-absorbent resin; in the present invention In , the polymeric water-absorbent resin...

Embodiment 1

[0060] ① 100 parts by weight of acrylic acid, 0.1 part by weight of polyethylene glycol diallyl ether (crosslinking agent); hydrophobic polymerization monomer m-chlorostyrene and cycloisoprene, the molar ratio is 1:1, a total of 30 parts by weight and 300 parts by weight of deionized water were stirred and mixed, and after uniform mixing, a mixture was obtained.

[0061] 2. add 10 parts by weight of water-based ethylene / vinyl acetate resin dispersion (water-based ethylene-vinyl acetate resin dispersion) to the mixture obtained, the average particle diameter of the resin polymer in the water-based resin dispersion is less than 400nm, and the mixed particles A diameter of 0.5 parts by weight of inorganic particle montmorillonite and 1:1 honeysuckle extract and peppermint extract in a mass ratio of 220nm add up to 0.5 parts by weight, nitrogen deoxygenation for 15min, to obtain a mixed solution; then in the mixed solution 0.04 parts by weight of ammonium bisulfite was added to in...

Embodiment 2

[0064] ① 100 parts by weight of acrylic acid, 0.1 part by weight of polyethylene glycol diallyl ether (crosslinking agent); hydrophobic polymerization monomer m-chlorostyrene and cycloisoprene, the molar ratio is 1:1, a total of 15 parts by weight and 250 parts by weight of deionized water were stirred and mixed, and after uniform mixing, a mixture was obtained.

[0065] 2. Add 8 parts by weight of water-based polyvinyl chloride resin and polyurethane resin mixed resin dispersion in the obtained mixture, the average particle diameter of the resin polymer in the water-based resin dispersion is less than 400nm, and the mixed particle diameter is 220nm inorganic particle montmorillonite Soil 0.5 parts by weight and a mass ratio of 1:1 honeysuckle extract, peppermint extract, a total of 0.5 parts by weight, nitrogen deoxygenation 18min, to obtain a mixed solution; then add 0.06 parts by weight of hydrogen sulfite to the mixed solution Ammonium initiates the polymerization reaction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com