Method for preparing LMO-YSZ composite solid electrolyte by microwave combustion supporting method

A LMO-YSZ, solid electrolyte technology, applied in fuel cells, circuits, electrical components, etc., can solve the problems of corrosion, slow decomposition of materials, interphase diffusion of metal connection materials, etc., to achieve energy saving, simple operation, and short synthesis time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The method for preparing LMO-YSZ composite solid electrolyte by microwave combustion-supporting method, the steps are as follows:

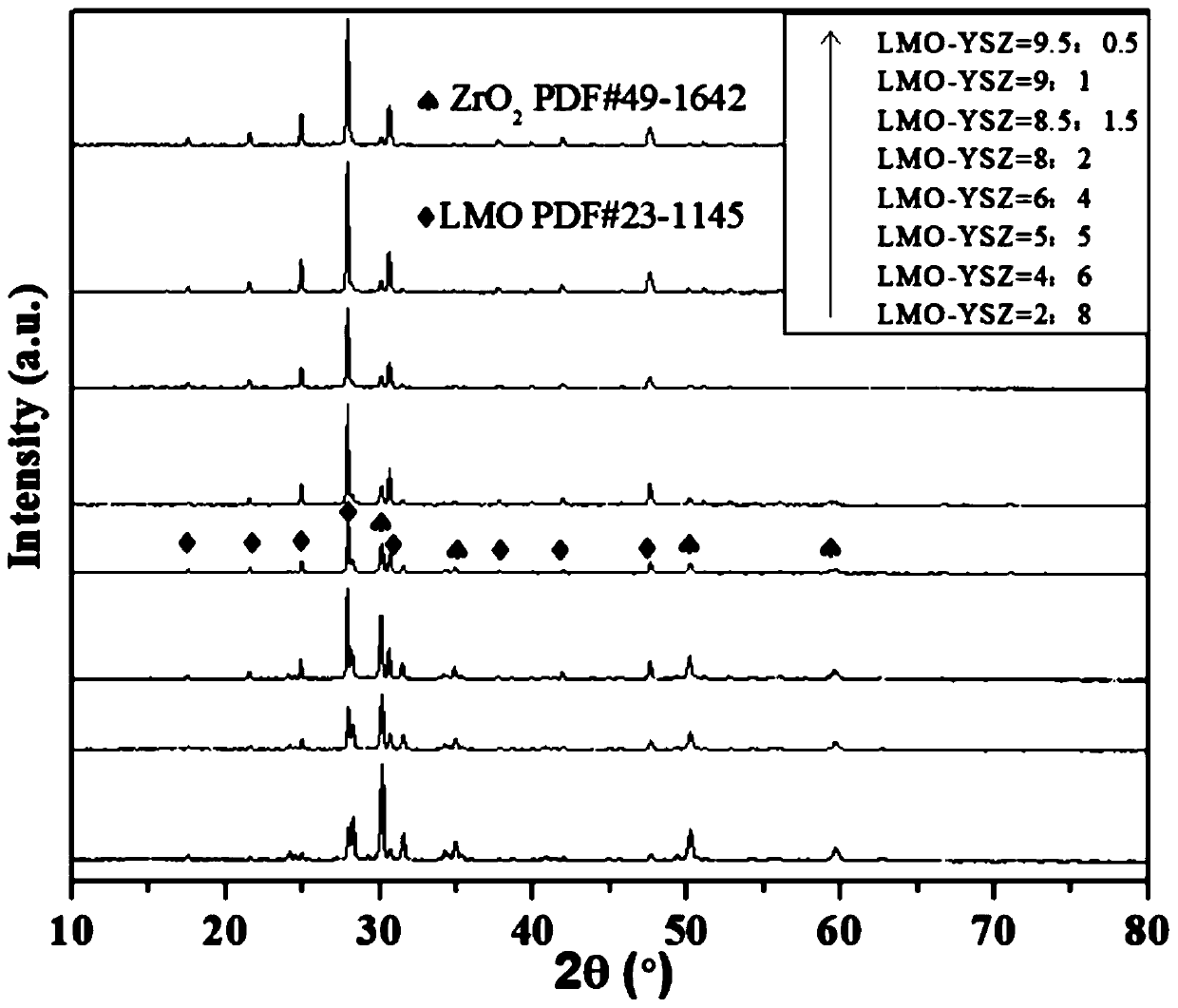

[0027] 1), according to La 2 Mo 2 o 9Weigh lanthanum nitrate and ammonium molybdate, add an appropriate amount of water according to the concentration requirement of 0.25mol / L, then add citric acid, stir and dissolve at 70°C with magnetic force, and adjust the pH value of the solution to neutral with ammonia water; then put Put it into a microwave oven, microwave combustion-supporting reaction at 300°C for 10min, the reaction product was washed, oven-dried at 120°C for 2h, and ground to obtain LMO. Preparation of Lanthanum Molybdate La by Microwave Combustion 2 Mo 2 o 9 That is, LMO, and then zirconium nitrate and yttrium nitrate are prepared by microwave combustion method to prepare yttrium-based zirconia Zr 0.92 Y 0.08 o 1.96 That is, YSZ, and finally LMO-YSZ composite solid electrolyte was obtained by ball milling and mixing.

...

Embodiment 2

[0039] The method for preparing LMO-YSZ composite solid electrolyte by microwave combustion-supporting method, the steps are as follows:

[0040] 1), according to La 2 Mo 2 o 9 Weigh lanthanum nitrate and ammonium molybdate, add appropriate amount of water according to the concentration requirement of 0.2mol / L, then add citric acid, stir and dissolve at 80°C, and adjust the pH value of the solution to neutral with ammonia water; then put Put it into a microwave oven, microwave combustion-supporting reaction at 280°C for 15min, the reaction product was washed, oven-dried at 100°C for 3h, and ground to obtain LMO.

[0041] 2), according to Zr 0.92 Y 0.08 o 1.96 Weigh zirconium nitrate and yttrium nitrate, add appropriate amount of water according to the concentration requirement of 0.35mol / L, then add citric acid, stir and dissolve at 55°C, and adjust the pH value of the solution to neutral with ammonia water; then add In a microwave oven, microwave combustion-supporting r...

Embodiment 3

[0045] The method for preparing LMO-YSZ composite solid electrolyte by microwave combustion-supporting method, the steps are as follows:

[0046] 1), according to La 2 Mo 2 o 9 Weigh lanthanum nitrate and ammonium molybdate, add appropriate amount of water according to the concentration requirement of 0.3mol / L, then add citric acid, stir and dissolve at 60°C with magnetic force, and adjust the pH value of the solution to neutral with ammonia water; then put Put it into a microwave oven, microwave combustion-supporting reaction at 320°C for 5 minutes, the reaction product was washed, oven-dried at 140°C for 1 hour, and ground to obtain LMO.

[0047] 2), according to Zr 0.92 Y 0.08 o 1.96 Weigh zirconium nitrate and yttrium nitrate, add appropriate amount of water according to the concentration requirement of 0.15mol / L, then add citric acid, stir and dissolve at 85°C, and adjust the pH value of the solution to neutral with ammonia water; then add In a microwave oven, micro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com