Mesoporous polyionic liquid catalyst for normal-pressure CO2 cycloaddition reaction as well as preparation method and application thereof

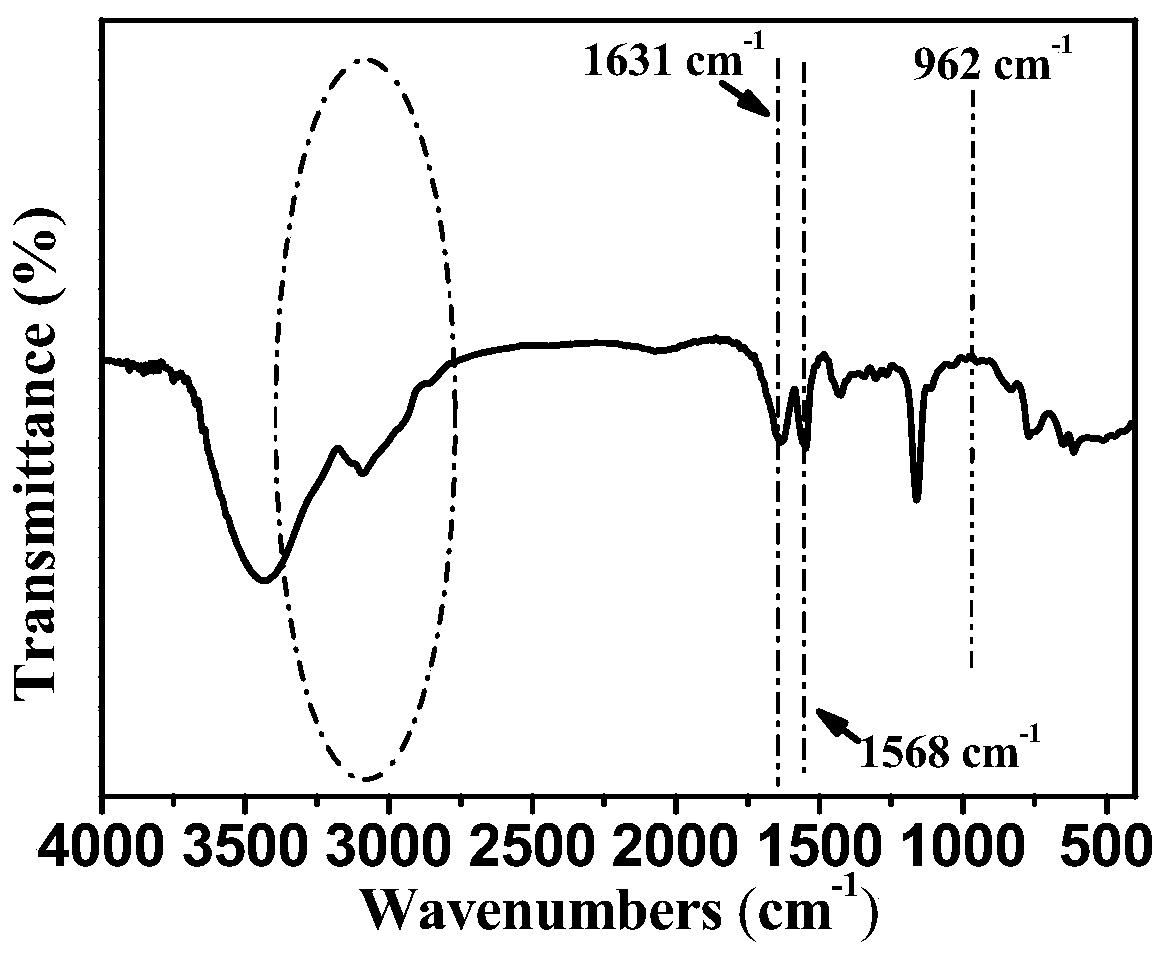

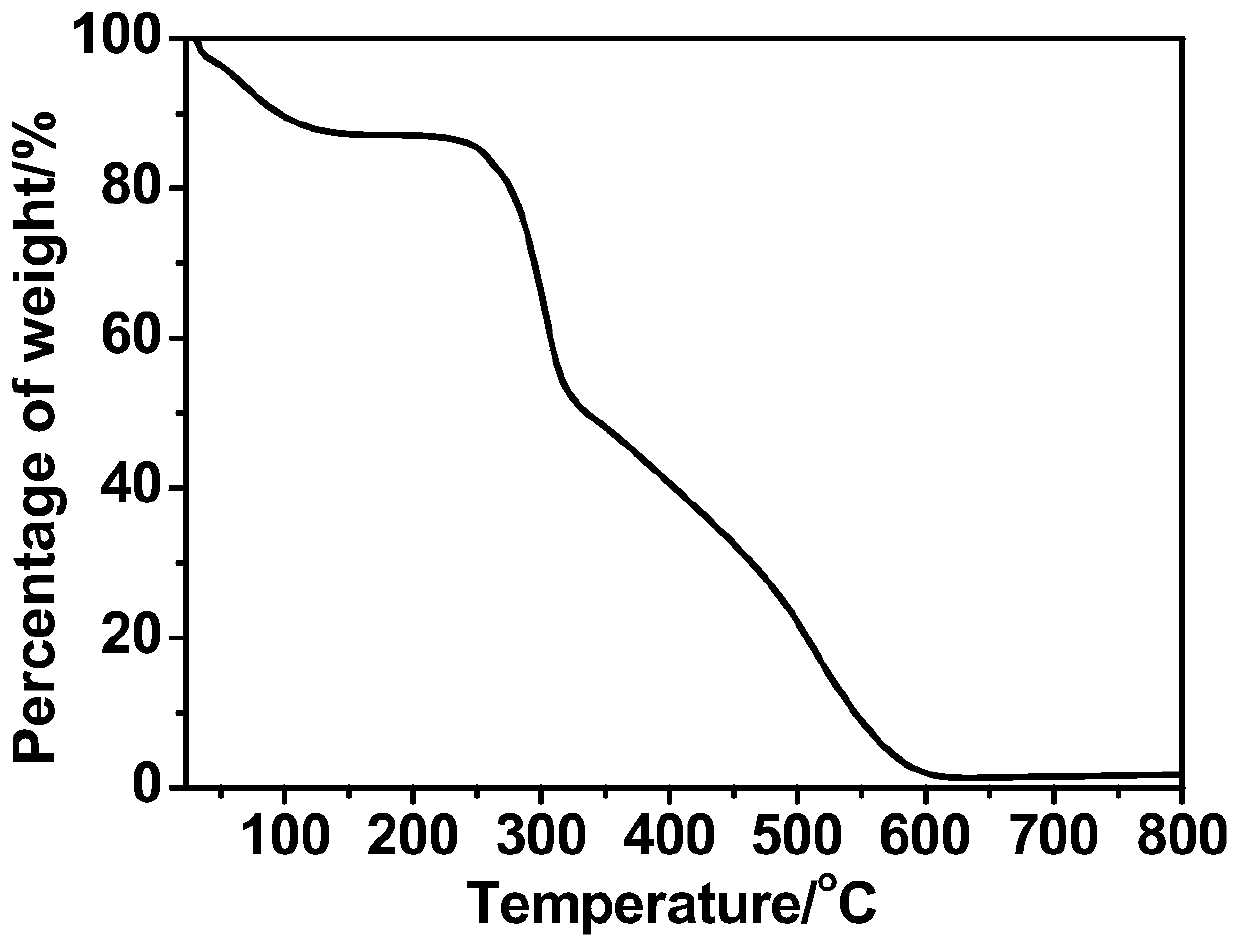

A technology of polyionic liquid and ionic liquid, which is applied in the field of preparation of heterogeneous catalysts in organic chemical industry, can solve problems such as high temperature and high pressure, and achieve the effects of good thermal stability, abundant halogen sites, and good recovery stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1) Dinuclear ionic liquid polymerized monomer bis-(3-vinyl-1-imidazole) methylene dibromide [C 1 Preparation of DVIM]Br

[0029] The preparation route is:

[0030]

[0031] Dissolve N-vinylimidazole (5.00g, 53.2mmol) and dibromomethane (4.62g, 26.6mmol) in 5mL of tetrahydrofuran, stir at room temperature for 1h, put it into a 100°C oven for solvent heat treatment for 24h, and after cooling to room temperature, get The crystalline yellow crude product was washed three times with ether and ethyl acetate respectively, filtered by suction and dried in a 70°C oven to obtain a yellow solid—monomer [C 1 DVIM] Br.

[0032] 2) Preparation of mesoporous polyionic liquids

[0033] The preparation route is:

[0034]

[0035] The monomer [C 1 DVIM] Br (0.3g), PEG-200 (6g) and initiator azobisisobutyronitrile AIBN (0.03g, [C 1 DVIM] 10% of the mass of Br) into the reaction tube, followed by 1 mL of deionized water, stirred at room temperature for 2 h, after the raw materi...

Embodiment 2

[0040] Effect of Different Polyethylene Glycols on Specific Surface Area of Prepared Products

[0041] The preparation process is the same as in Example 1, and the polyethylene glycol is replaced by PEG-400, PEG-600, and PEG-800 respectively from PEG-200, and the specific surface areas of the prepared products are as follows: 185m 2 .g -1 、173m 2 .g -1 、164m 2 .g -1 , by comparison, it can be found that under the same preparation conditions, as the molecular weight of polyethylene glycol gradually increases, the specific surface area of the prepared product gradually decreases.

Embodiment 3

[0043] 1) Dinuclear ionic liquid polymerized monomer bis-(3-vinyl-1-imidazole) methylene dibromide [C 1 Preparation of DVIM]Br

[0044] Dissolve N-vinylimidazole (7.05g, 75.01mmol) and dibromomethane (5.21g, 29.99mmol) in 10mL of tetrahydrofuran, stir at room temperature for 0.5h, put it into a 120°C oven for solvent heat treatment for 30h, and after cooling to room temperature, A crystalline yellow crude product was obtained, which was washed three times with ether and ethyl acetate, filtered by suction and dried in an oven at 80°C to obtain a yellow solid—monomer [C 1 DVIM] Br.

[0045] 2) Preparation of mesoporous polyionic liquids

[0046] The monomer [C 1 DVIM]Br (0.1g), PEG-400 (5g) and initiator 2,2'-azobis(2-methylpropylamidine) dihydrochloride (0.02g, [C 1 DVIM] 20% of the mass of Br) into the reaction tube, followed by 1 mL of deionized water, stirred at room temperature for 2.5 h, after the raw materials were fully dissolved, heated in an oil bath at 80° C. for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com