Graphite oxide acetylene nanosheet achieving water photolysis oxygen generation under visible light and preparation method and application thereof

A technology of graphyne and nanosheets, which is applied in the field of graphyne oxide nanosheets and its preparation, can solve the problems of unresearched, complex preparation process, and unfavorable large-scale application of visible light water splitting oxygen generation, and achieve excellent photolysis water oxygen generation performance , Improve light absorption, high-performance visible light water splitting and oxygen production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

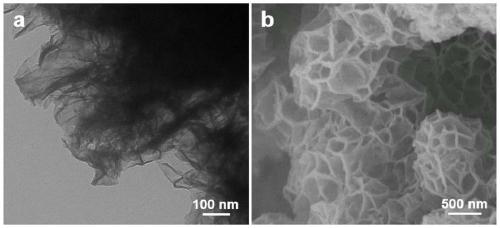

Image

Examples

preparation example Construction

[0030] The invention provides a preparation method of graphyne oxide nanosheets for photolysis of water to generate oxygen under visible light, comprising the following steps:

[0031] A) oxidizing graphyne by mixed strong acid to obtain graphyne oxide;

[0032] B) Exfoliating the graphyne oxide by liquid-phase ultrasonic stripping, and obtaining graphyne oxide nanosheets after centrifugation.

[0033] The present invention uses graphyne as a raw material to prepare graphyne oxide nanosheets, wherein the graphyne is prepared according to the following method:

[0034] The acetone solution of hexaynylbenzene is added to the mixed solution of acetone, pyridine and tetramethylethylenediamine dispersed with copper flakes, and nitrogen is used as a protective gas, and the reaction is carried out under heating conditions to obtain graphyne.

[0035] The concentration of hexaynylbenzene in the acetone solution of hexaynylbenzene is 0.8 mg / ml-1.0 mg / ml.

[0036] The volume ratio of ...

Embodiment 1

[0065] Mix 100 milliliters of acetone, 5 milliliters of pyridine and 1 milliliter of tetramethylethylenediamine to form a solution, add 50 mg of clean copper, and then, under the protection of nitrogen atmosphere, mix 50 milliliters of six The acetone solution of alkynylbenzene was injected into the above solution at a rate of 25 ml / hour using a syringe pump. The mixed system was reacted for 24 hours in an oil bath at 50° C. under the protection of a nitrogen atmosphere. Finally, the sample is fully washed with hot acetone, pyridine, and N,N-dimethylformamide in sequence to remove unreacted monomers and oligomers to obtain a graphyne sample.

Embodiment 2

[0067] At 0°C, 5 ml of concentrated sulfuric acid and 10 ml of concentrated nitric acid were mixed, and then 50 mg of graphyne sample was slowly added to the mixture. The reaction was stirred magnetically at room temperature for 6 hours. Dilute the dispersion with 200 ml of deionized water, collect the sample by centrifugation, wash thoroughly with deionized water until the pH of the separated liquid is neutral, and dry it in vacuum at room temperature to obtain a sample of graphyne oxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com