Method and device for femtosecond laser preparation of diamond tool

A diamond cutting tool and femtosecond laser technology, applied in laser welding equipment, metal processing equipment, welding equipment, etc., can solve the problems of difficult removal of diamond materials, low processing efficiency, poor grinding quality, etc., and achieve simple and reliable structure, The effect of low device cost, high precision and high quality preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

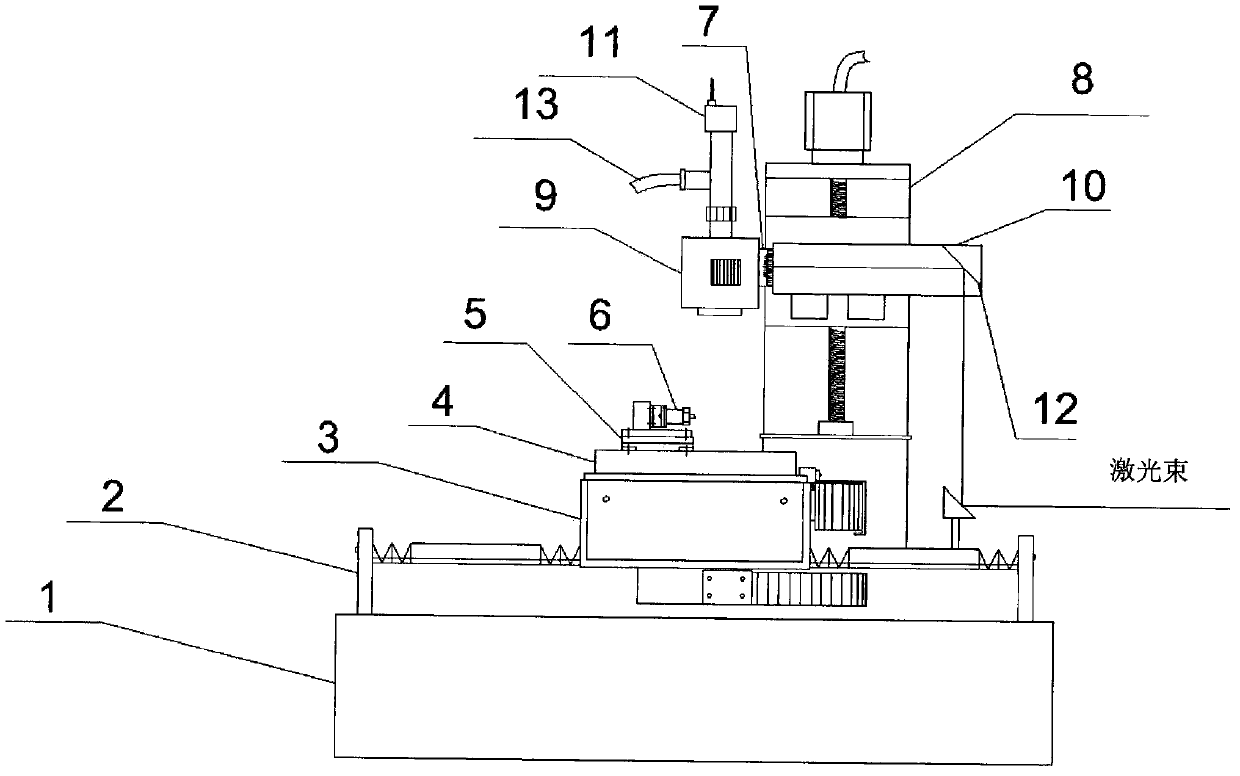

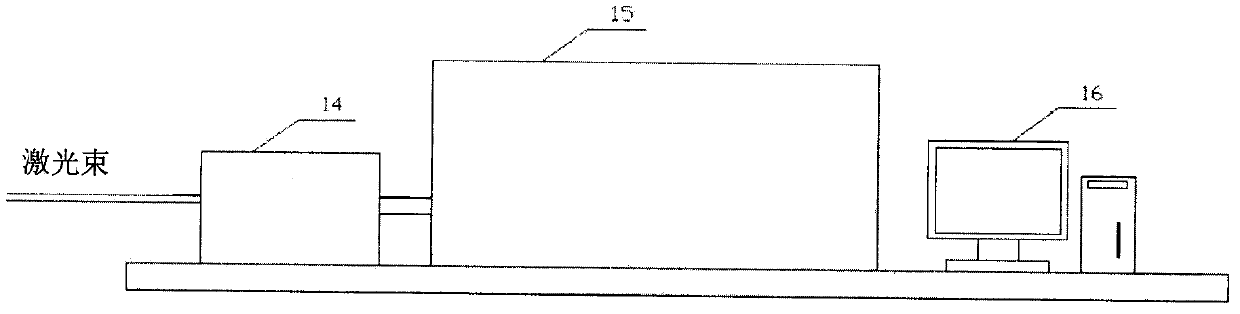

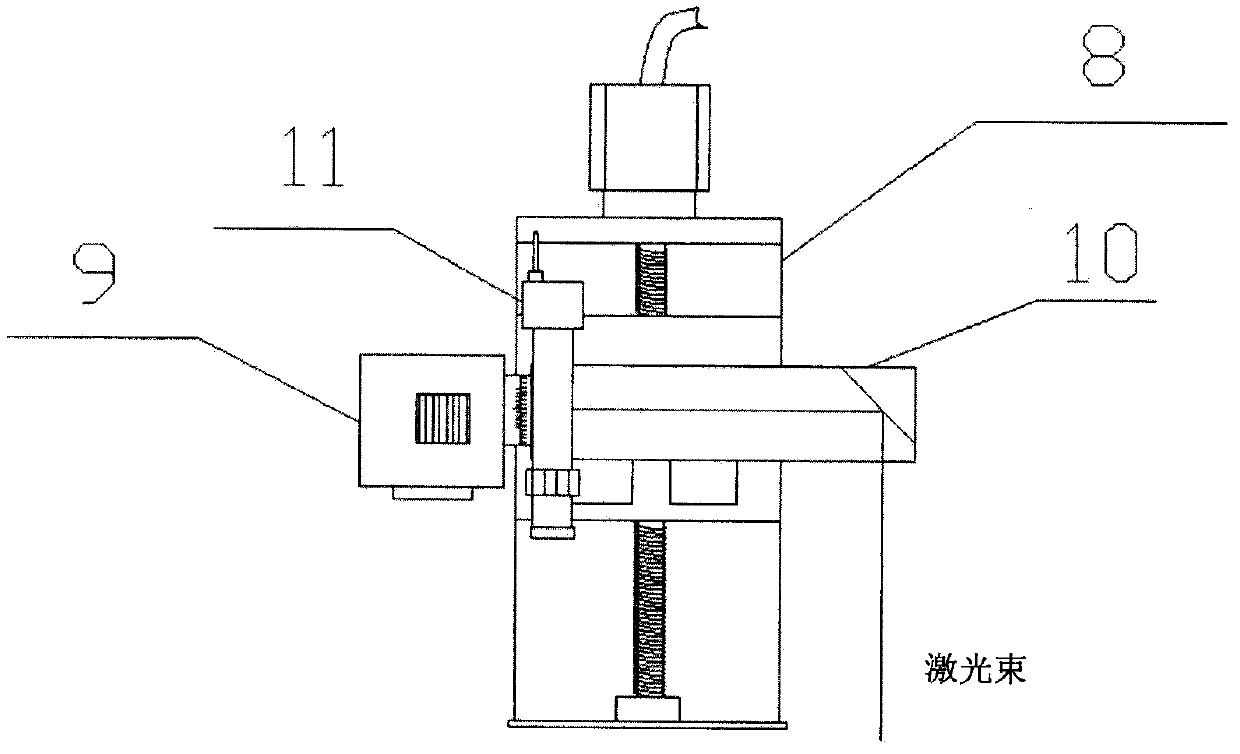

[0024] The invention relates to a femtosecond laser preparation method and device for diamond tools, which are suitable for high-efficiency, high-precision preparation, shaping and polishing of PCD (polycrystalline diamond), single crystal diamond and CVD diamond tools.

[0025] Adopt the device of the present invention to prepare the main steps of diamond cutter as follows:

[0026] Step 1, clamping the diamond tool parts on the tool clamping device 6, the tool head is exposed at least 1 cm long, so that the part to be processed can be focused by the laser without shielding;

[0027] Step 2, adjust the positions of the X-direction linear motor 2 and the Y-direction linear motor 3 through the numerical control program, move the cutter to the laser vibrating mirror 9 and the coaxial or off-axis CCD microscope 11, and use the real-time measurement function of the CCD microscope 11 to move the cutter Adjust the head to the exact position to be processed;

[0028] Step 3, when pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com