Fluid power generation method and device based on funnel-shaped nano channel film

A technology of nano-channels and power generation devices, which is applied to generators, generators/motors, and electrical components that convert kinetic energy into electrical energy. , low energy consumption, high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

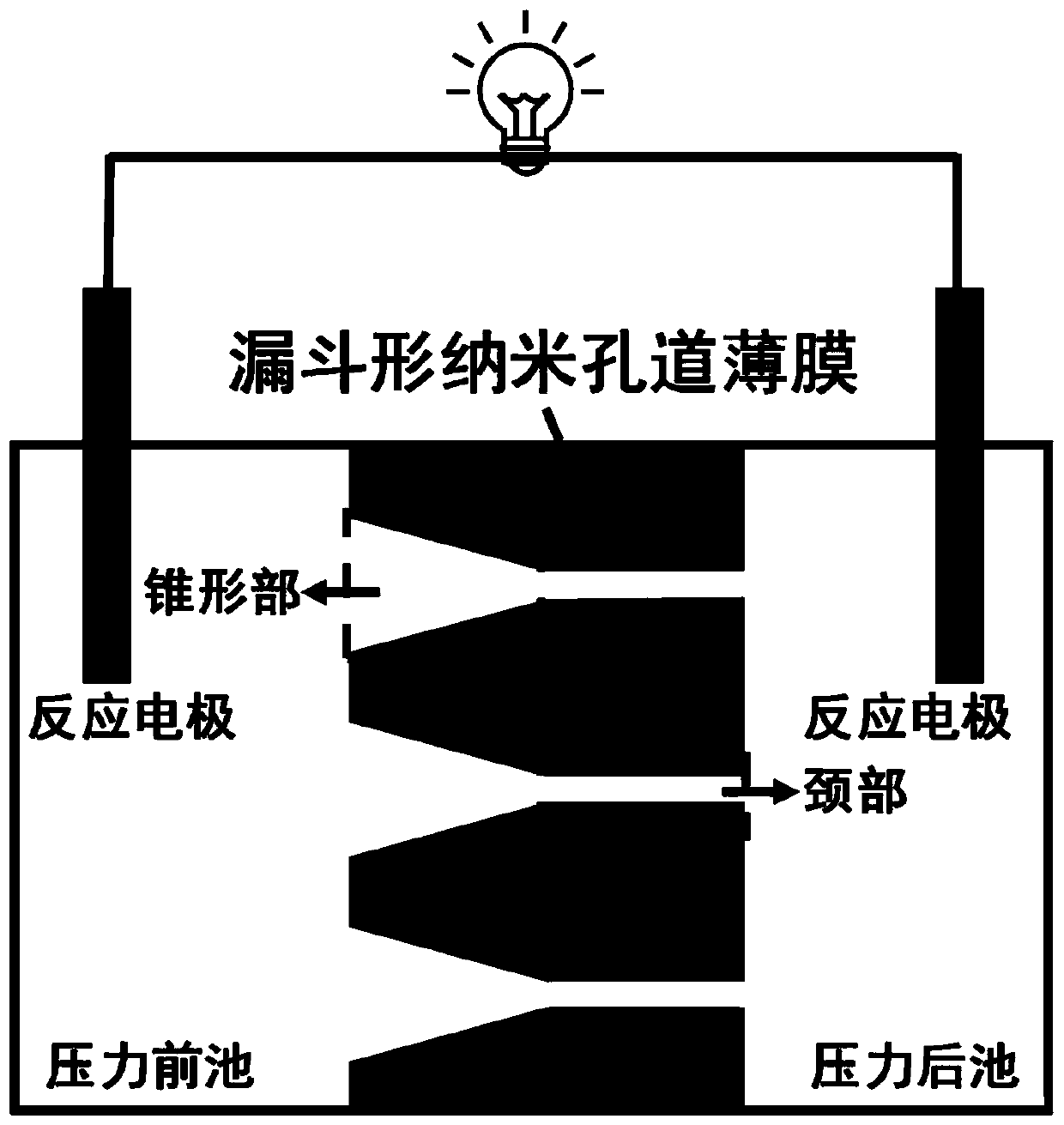

[0069] figure 1 The fluid power generation device used in the present invention is mainly composed of a hydraulic device and a power generation module. 1. Liquid storage tank; 2. Pressure front tank; 3. Pressure back tank; 4. Funnel-shaped nanoporous membrane; 5. Peristaltic pump; 6. Peristaltic pump; 7. Valve; 8. Valve; 9. Valve; 10. valve.

[0070] The material of the funnel-shaped nanochannel film in the device is polyethylene terephthalate, its thickness is 12 μm, the diameter of the open end of the tapered part is 350 nm, the length of the tapered part is 5 μm, and the diameter of the open end of the neck is 12 nm. , the length of the neck is 7 μm. The electrode is a filamentous silver chloride electrode, with a length of about 5cm and a diameter of about 1mm; the working fluid in the pressure forebay and the pressure after pool is 0.1M potassium chloride solution, and its pH is 5.5; the prepressure provided by the peristaltic pump The pressure difference between the p...

Embodiment 2

[0076] Generating device and generating process are exactly the same as embodiment 1, just changed the following parameters in the generating device:

[0077] The material of the funnel-shaped nanochannel film in the device is polyethylene terephthalate, its thickness is 12 μm, the diameter of the opening end of the tapered part is 165 nm, the length of the tapered part is 5 μm, and the diameter of the opening end of the neck is 9 nm , the length of the neck is 7 μm. The electrode is a filamentous silver chloride electrode with a length of about 5 cm and a diameter of about 1 mm; the working fluid in the pressure forebay and the pressure back pool is 0.1M potassium chloride solution, and its pH is 5.5; the pressure provided by the peristaltic pump 5 The pressure difference between the forebay and the post-pressure pool is 0.9-1.1MPa.

[0078] It is obtained through detection that the magnitudes of the bidirectional currents are 10nA and 8nA respectively.

Embodiment 3

[0080] Generating device and generating process are exactly the same as embodiment 1, just changed the following parameters in the generating device:

[0081] The material of the funnel-shaped nanochannel film in the device is polyethylene terephthalate, its thickness is 12 μm, the diameter of the opening end of the tapered part is 165 nm, the length of the tapered part is 3 μm, and the diameter of the opening end of the neck is 9 nm , the length of the neck is 9 μm. The electrode is a filamentous silver chloride electrode, with a length of about 5cm and a diameter of about 1mm; the working fluid in the pressure forebay and the pressure after pool is 0.1M potassium chloride solution, and its pH is 5.5; the prepressure provided by the peristaltic pump The pressure difference between the pool and the post-pressure pool is 0.9-1.1M Pa.

[0082] It is obtained through detection that the magnitudes of the bidirectional currents are 11nA and 12nA respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com