An energy-saving scheduling model of a hybrid assembly line forging workshop under multiple time factors

A forging workshop and time factor technology, applied in manufacturing computing systems, special data processing applications, instruments, etc., can solve problems such as high energy consumption, inability to estimate waste energy consumption of equipment, and increase the difficulty of production scheduling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

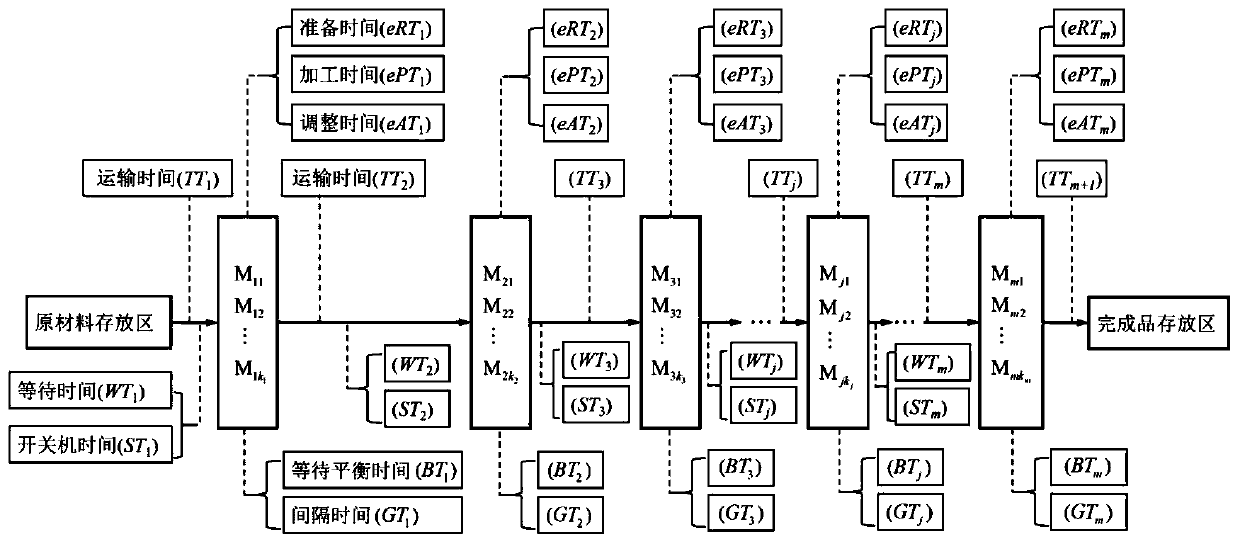

[0074] The forging production model established in this invention not only considers the time of many different manufacturing stages, but also proposes a right-shifting rule of transportation time, which is used in the production planning of continuous processing of heating furnace equipment and discrete processing of machining equipment Sorting, establishing a trade-off model of the completion time and energy consumption of the mixed flow forging workshop scheduling. Below in conjunction with accompanying drawing and specific embodiment, the present invention will be further described:

[0075] Step 1 Build a mixed flow shop model under various time factors

[0076] Such as figure 1 As shown, the model of a general mixed flow workshop is described. The materials start from the raw material storage area, go through each processing stage in turn, and finally arrive at the finished product storage area. Each processing stage has the same parallel equipment, and when the materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com