Reliability Test System of Shaft Type Oil Distributor

A test system and oil distributor technology, which is applied in the testing of machines/structural components, instruments, mechanical components, etc., can solve the problems of heavy workload of axial oil distributors, and avoid leakage and heavy workload , to ensure the effect of stable rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the object, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

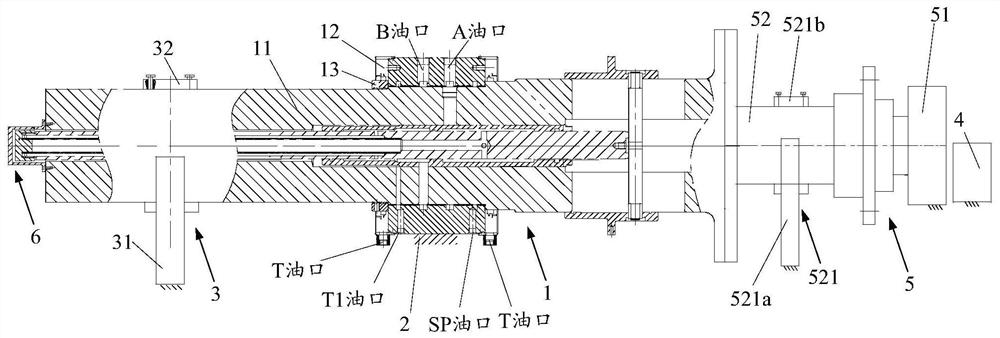

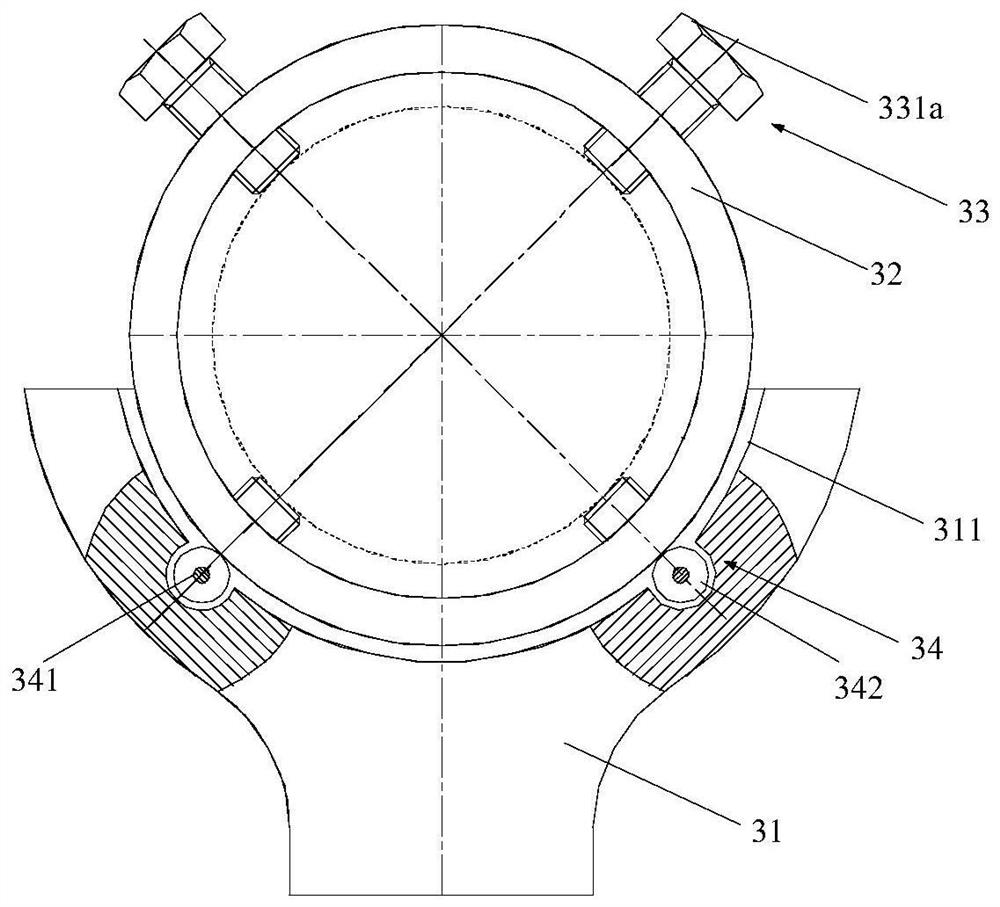

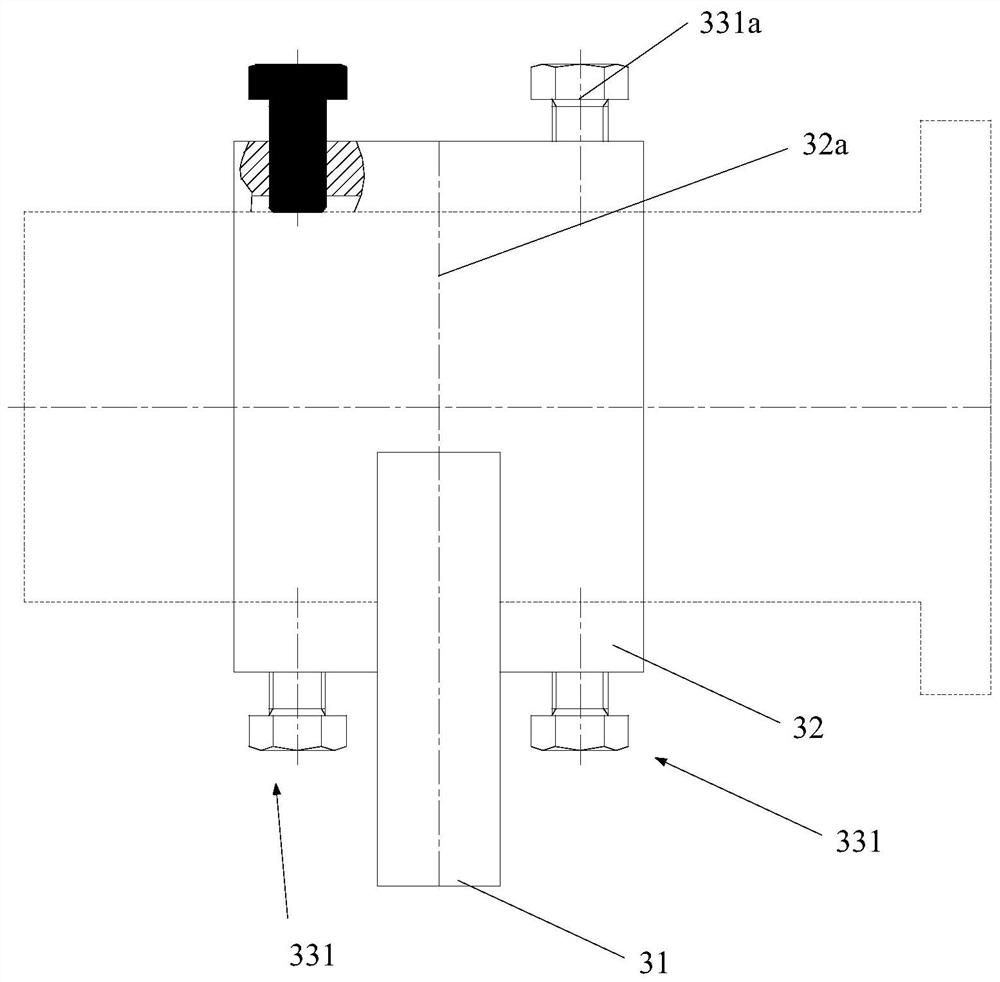

[0035] figure 1 It is an assembly schematic diagram of the axial oil distributor and the reliability test system of the axial oil distributor provided by the embodiment of the present invention. In order to facilitate the understanding of the present invention, the structure of the axial oil distributor 1 will be described first. 1 At least including an oil distribution shaft 11 and an oil distribution ring 12 coaxially sleeved on the oil distribution shaft 11, an oil deflector ring 13 is arranged between the oil distribution ring 12 and the oil distribution shaft 11, and the oil deflector ring 13 connects the oil distribution ring 12 is fixed on the oil distribution shaft 11, and the hydraulic oil that may exist between the oil distribution rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com