Surface finishing machine and finishing method of finned evaporation tube of refrigeration equipment

A technology for surface finishing and refrigeration equipment, used in manufacturing tools, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of increasing operator workload, inability to grind at incisions, low grinding efficiency, etc., to avoid It is not easy to grind, enhance the clamping effect, and improve the work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

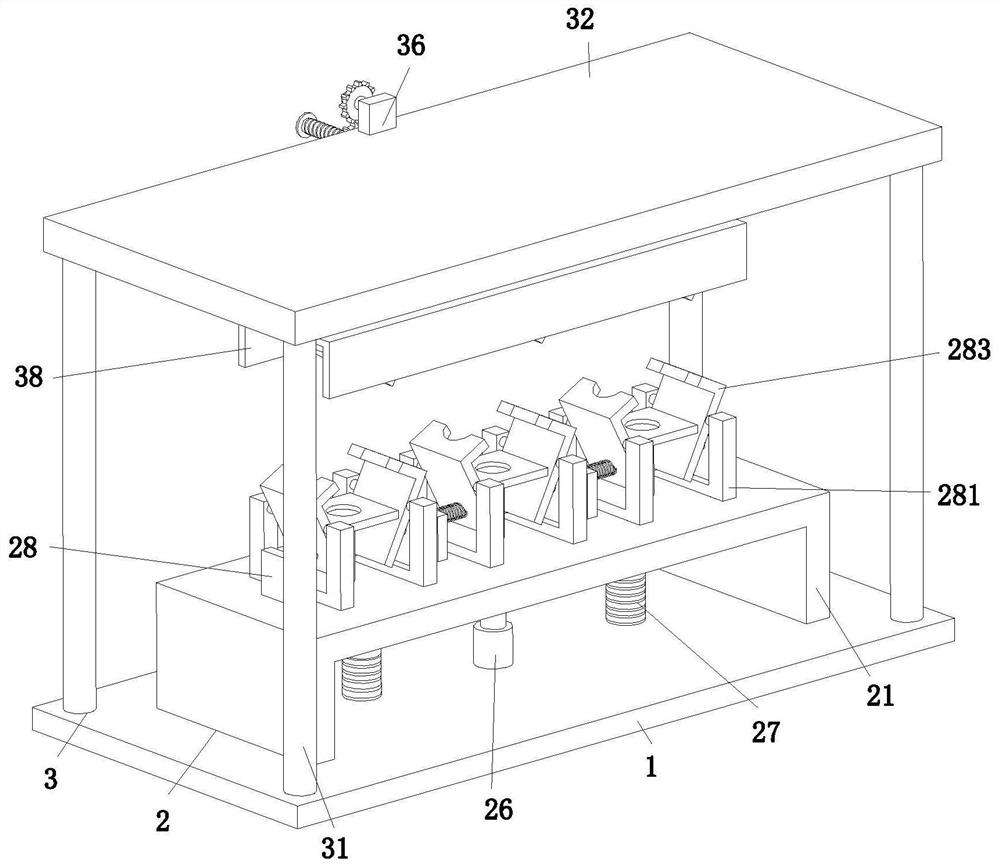

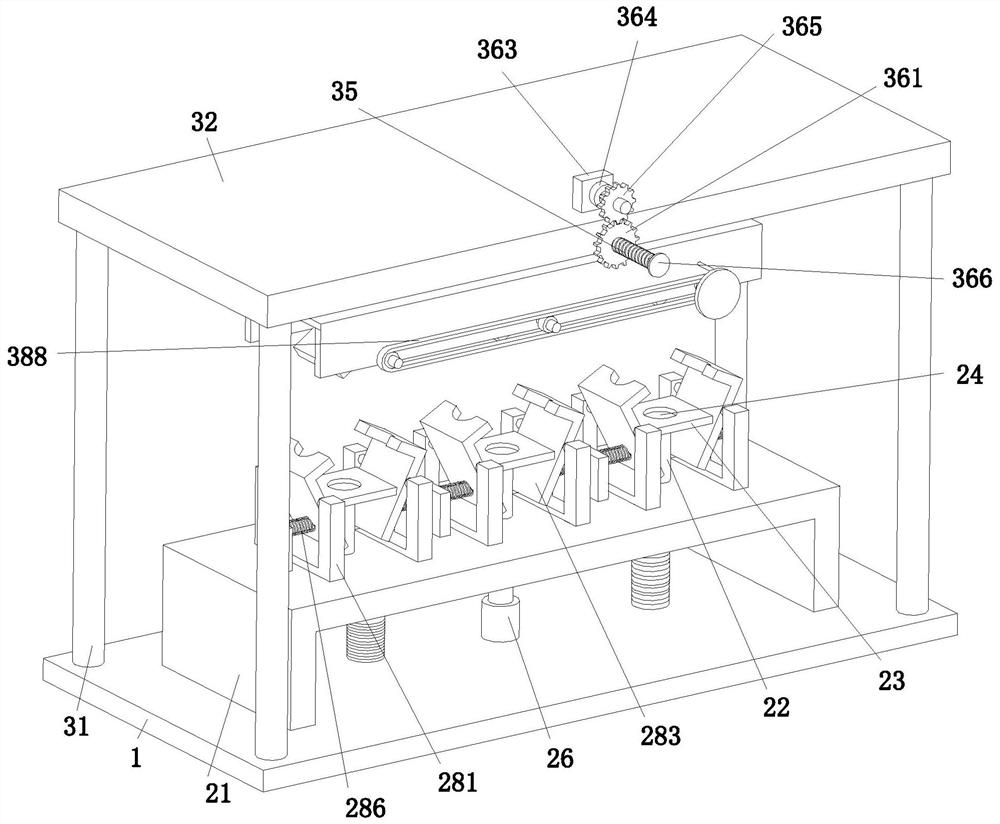

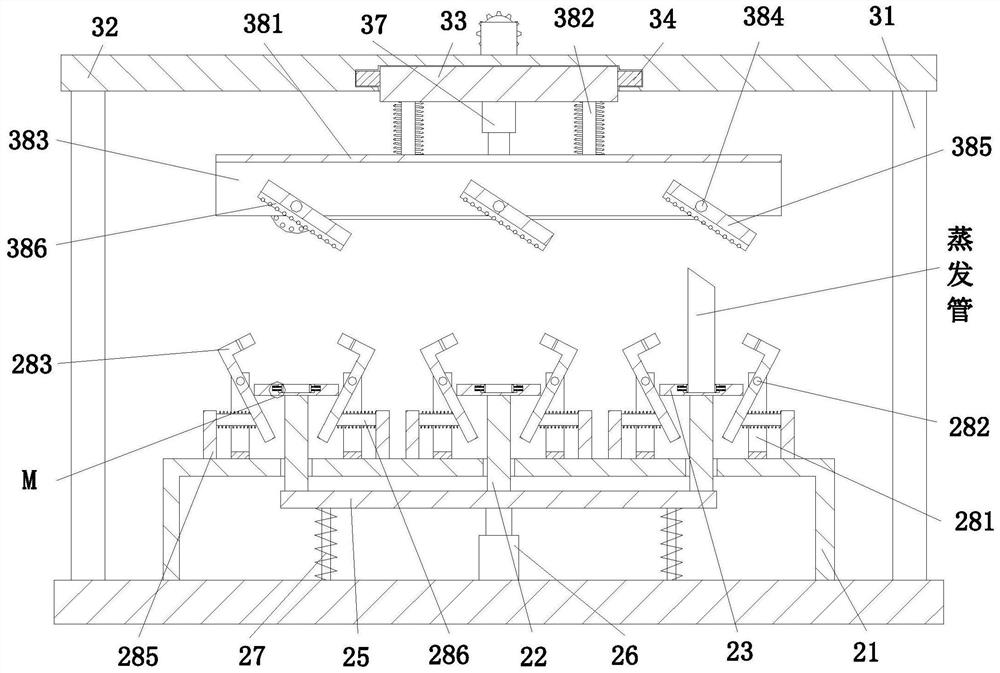

[0036] In order to make the technical means, creation features, achievement goals and effects realized by the present invention easy to understand and understand, the following combination Figure 1 to Figure 10 , the present invention will be further elaborated.

[0037]A refrigerating equipment fin evaporation tube surface finishing machine, comprising a workbench 1, a fixing device 2 and a grinding device 3, and the top of the workbench 1 is provided with a fixing device 2 and a grinding device 3;

[0038] The fixing device 2 includes a profiled frame 21, a cylindrical rod 22, a fixing plate 23, a No. 1 circular groove 24, a push plate 25, an electric push rod 26, a spring telescopic rod 27 and a clamping frame 28. The top of the workbench 1 is fixedly installed with a profile frame 21 with an opening downward, the top of the profile frame 21 is evenly provided with moving holes from left to right, and a cylindrical rod 22 is slidably arranged in the mobile hole, and the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com