Method for preparing cigarette tipping paper from waste tobacco rods

A technology for cigarette tipping paper and cigarette rods, which is applied in papermaking, paper, special paper and other directions, can solve problems such as non-scale, and achieve the effect of reducing the complexity of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

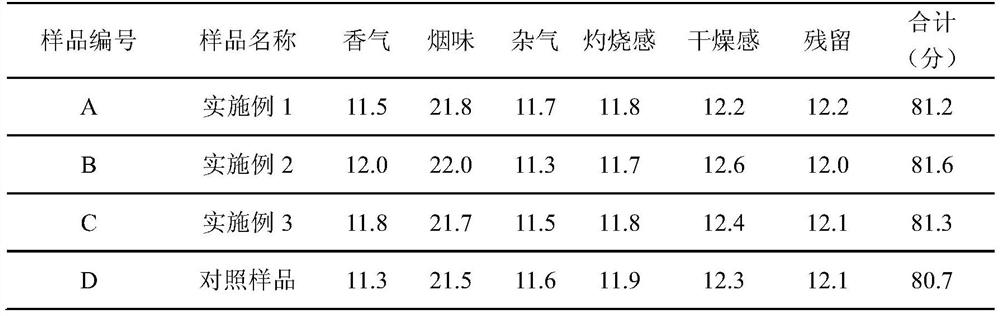

Examples

Embodiment 1

[0027] A method for preparing cigarette tipping paper with waste tobacco rods provided in Example 1, the specific steps are as follows:

[0028] (1) Slice the tobacco rods that have undergone wet depilling and semi-fiber removal into 3cm-long pieces, and then soak them in the steam chamber for 300min at a temperature of 60°C. The rotating speed is 500rpm, and the pulp concentration is 20%;

[0029] (2) Selectively degrade lignin, protein, pectin, part of starch and cellulose etc. through the fiber of step poly(1) through micro-ecological regulating agent, the consumption of micro-ecological regulating agent is 0.3%, and fermentation temperature is 55 ℃, pre- The treatment time is 60 minutes, and after the fermentation is completed, the fermentation broth and the fermented tobacco rod fiber are collected respectively;

[0030] (3) Add NaOH (0.5%) to the fermented tobacco rod fibers collected in step (2), adjust the concentration to 12%, and use a disc refiner to refine in two ...

Embodiment 2

[0035] A method for preparing cigarette tipping paper with waste tobacco rods provided in Example 2, the specific steps are as follows:

[0036] (1) Chip the tobacco rods that have undergone wet depilling and semi-fiber removal into 4cm-long pieces, and then soak them in a steam chamber for 350 minutes at a temperature of 70°C. The rotating speed is 300rpm, and the pulp concentration is 15%;

[0037] (2) Selectively degrade the lignin and some hemicelluloses from the fiber of step (1) through the micro-ecological regulator, the dosage is 0.8%, the fermentation temperature is 35°C, and the pretreatment time is 90min; after the fermentation is completed, the fermentation broth is collected respectively and fermented tobacco rod fiber;

[0038] (3) Add NaOH (amount of 1.0%) to the fermented tobacco rod fibers collected in step (2), adjust the concentration to 15%, and use a disc refiner to refine in two stages. The refining gap is 0.5mm, the cycle is 4 times, the slurry through...

Embodiment 3

[0043] A method for preparing cigarette tipping paper with waste tobacco rods provided in Example 3, the specific steps are as follows:

[0044] (1) Chip the tobacco rods that have undergone wet depilling and semi-fiber removal into 5cm-long pieces, and then soak them in the steam chamber for 300min at a temperature of 90°C. The rotating speed is 400rpm, and the pulp concentration is 25%;

[0045] (2) Selectively degrade the lignin and some hemicelluloses from the fiber of step (1) through the micro-ecological regulator, the dosage is 1.5%, the fermentation temperature is 45°C, and the pretreatment time is 40min; after the fermentation is completed, the fermentation broth is collected respectively and fermented tobacco rod fiber;

[0046] (3) NaOH (1.0%) is added to the fermented tobacco rod fibers collected in step (2), the concentration is adjusted to 15%, and the pulp is refined in two stages by a disk refiner. In the first stage of refining, the disc refining gap is 0.2m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| opacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com