Hydrogenated nitrile rubber and unsaturated non-polar rubber laminated composite bonding transition layer compound

A technology of hydrogenated nitrile rubber and non-polar rubber, which is applied in the field of composite rubber products and can solve problems such as poor oil resistance, poor solvent resistance, and poor aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] transition layer compound

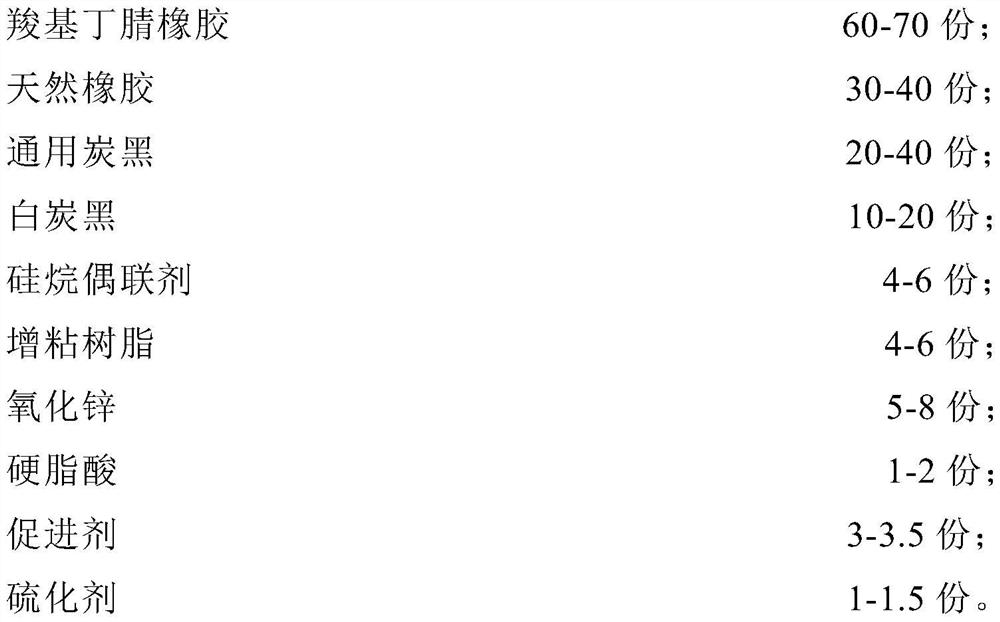

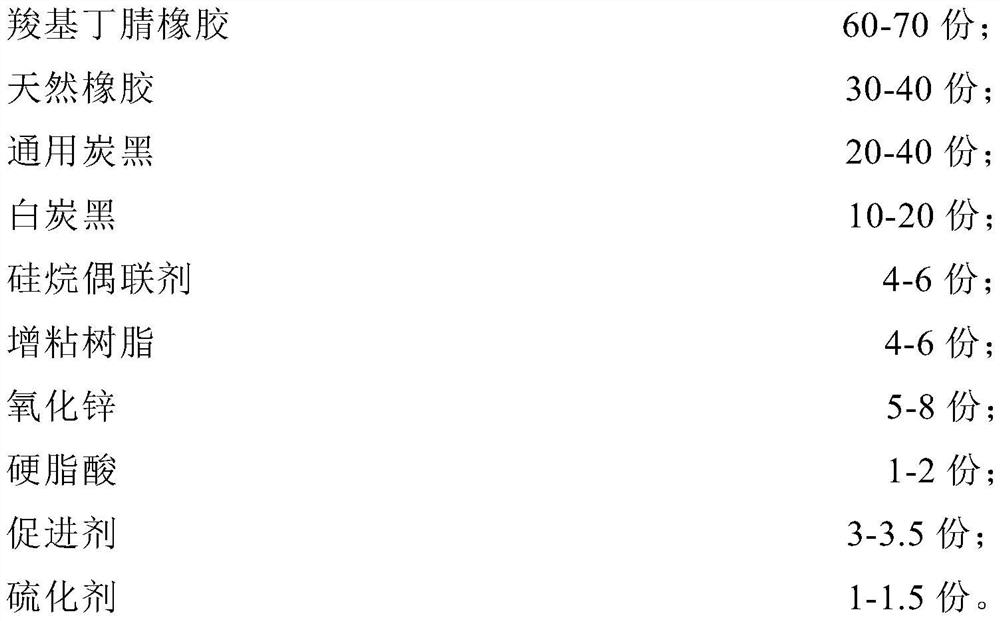

[0081] 1. The rubber compound for the transition layer is prepared from the following mass fractions of raw materials:

[0082] transition layer compound Carboxylated nitrile rubber (Nandi 1072CG) 60 copies natural rubber 40 copies N550 carbon black 40 copies Silica 10 copies Silane coupling agent bis-[γ-(triethoxysilyl)propyl]tetrasulfide 4 parts Tackifying resin (phenolic tackifying resin SP-1068) 6 servings Zinc oxide 5 copies stearic acid 1 copy Accelerator N-cyclohexyl-2-benzothiazole sulfenamide 2 copies Accelerator tetramethylthiuram disulfide 1 copy vulcanizing agent insoluble sulfur 0.6 parts

[0083] 2. The rubber material of the transition layer is bonded with hydrogenated nitrile rubber, natural rubber, natural rubber / styrene-butadiene rubber, natural rubber / butadiene rubber, respectively Films of the same thickness are made by calendering...

Embodiment 2

[0095] transition layer compound

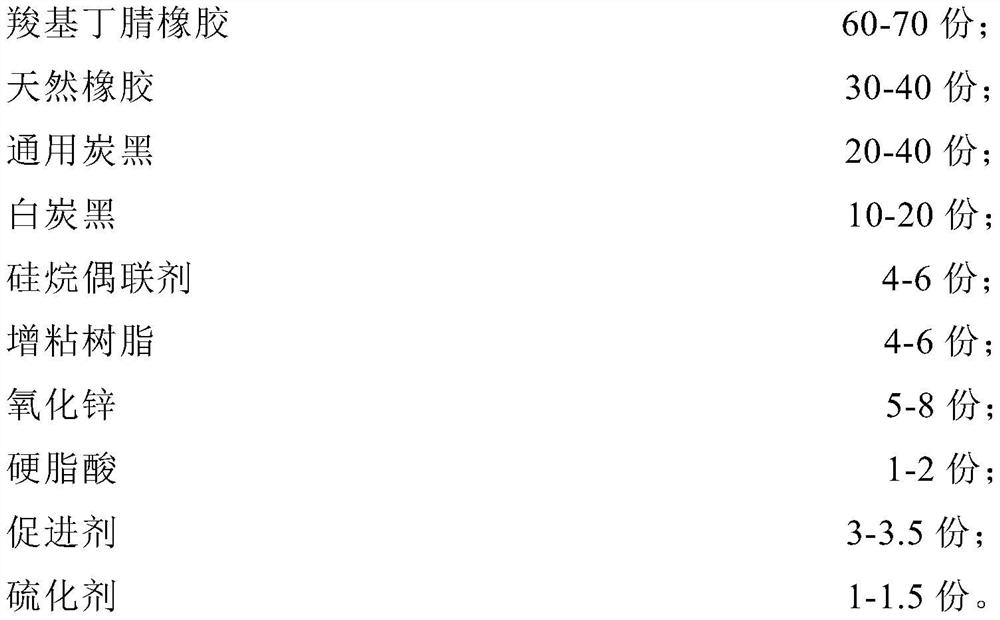

[0096] 1. The rubber compound for the transition layer is prepared from the following mass fractions of raw materials:

[0097] transition layer compound Carboxylated nitrile rubber (Nandi 1072CG) 70 copies natural rubber 30 copies N550 carbon black 30 copies Silica 20 copies Silane coupling agent bis-[γ-(triethoxysilyl)propyl]tetrasulfide 6 servings Tackifying resin (phenolic tackifying resin SP-1068) 4 parts Zinc oxide 8 servings stearic acid 2 copies Accelerator N-cyclohexyl-2-benzothiazole sulfenamide 2 copies Accelerator tetramethylthiuram disulfide 1.5 servings vulcanizing agent insoluble sulfur 1.5 servings

[0098] 2. The rubber material of the transition layer is bonded with hydrogenated nitrile rubber, natural rubber, natural rubber / styrene-butadiene rubber, natural rubber / butadiene rubber, respectively Films of the same thickness are made b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com