A method for co-producing yeast glucan, mannoprotein and yeast extract using β-1,6 glucanase

A technology of yeast extract and yeast glucan, applied in the field of co-production of yeast glucan, mannoprotein and yeast extract, can solve the problems of unknown enzymatic activity and cost, and avoid the complexity of equipment and operation. , reduce cost, improve the effect of purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

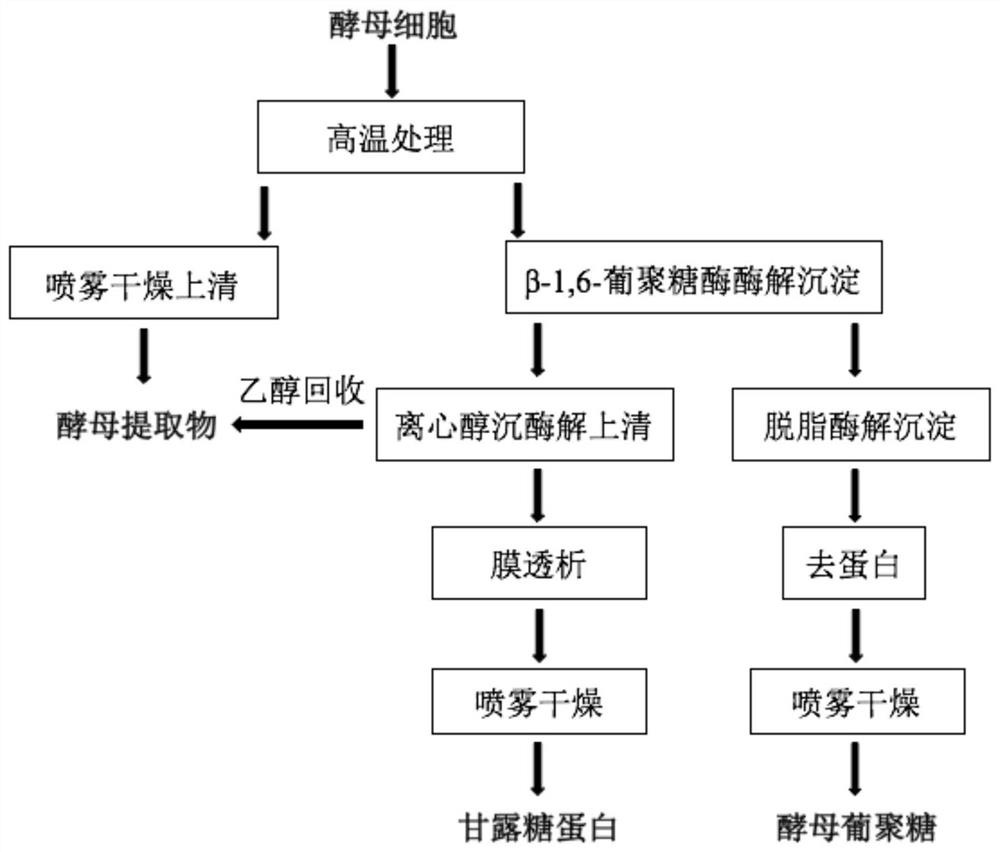

[0053] Example 1 A method for co-producing yeast glucan, mannoprotein and yeast extract using β-1,6 glucanase, using baker's yeast as a raw material, comprising the following steps (such as figure 1 shown):

[0054] (1) Using baker's yeast as a raw material, the yeast cells are prepared into a suspension with a mass percentage concentration of 9%, and the temperature is 110 ° C, the time is 20 minutes, and the pressure is 0.1 Mpa. Under the conditions of high temperature inactivation, the suspension The liquid was centrifuged at 8000rpm for 10min, and the precipitate and the supernatant were collected respectively: the precipitate was the treated yeast cell wall; the supernatant was concentrated and spray-dried to obtain the yeast extract;

[0055] (2) Corallococcus sp. EGB was inoculated in VY / 4 liquid enzyme production medium (0.40% yeast cell wall, 0.1% CaCl 2 , 0.1% yeast extract (w / v), pH 7.0), fermented and cultured for 2 days, collected the enzyme liquid by centrifugat...

Embodiment 2

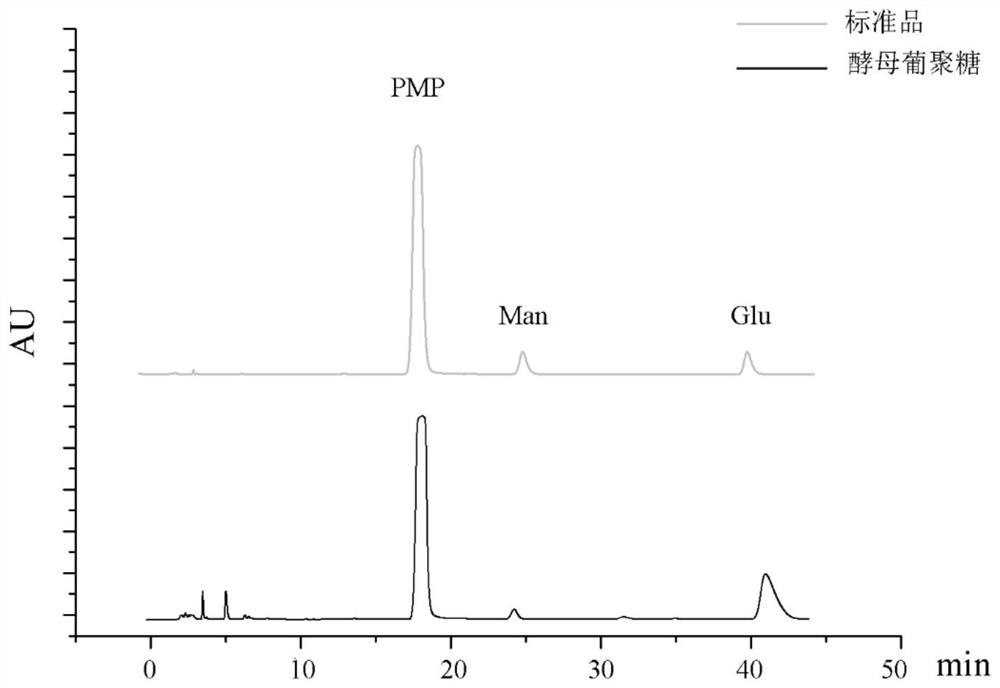

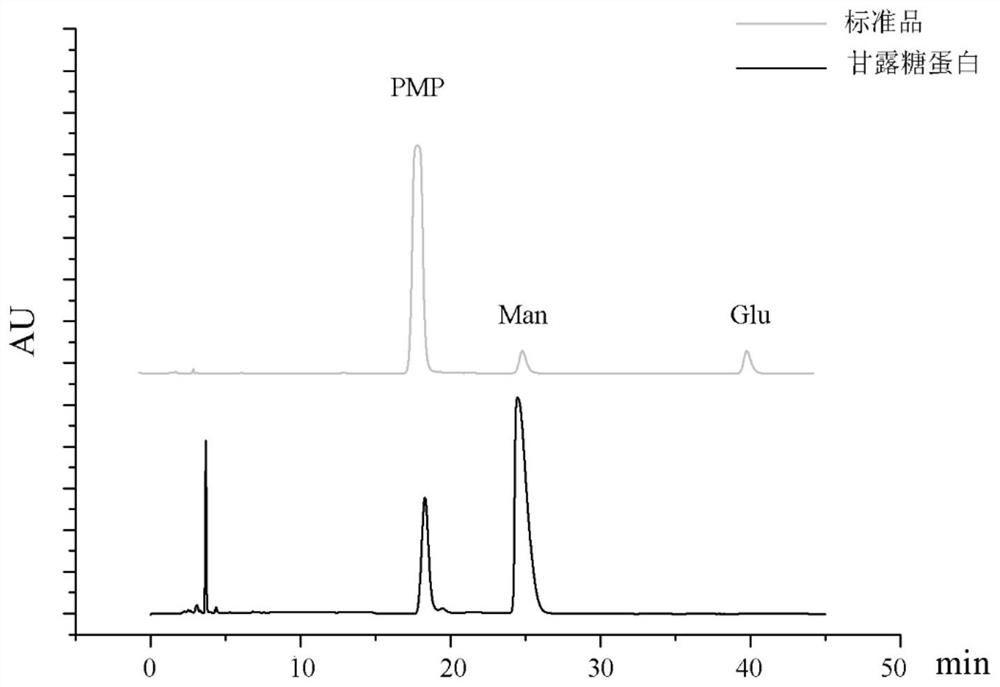

[0066] About 20 mg of yeast glucan and mannoprotein obtained in Example 1 were weighed, 10 mL of trifluoroacetic acid (4M) was added, and hydrolyzed at 100° C. for 4 h. The hydrolyzate was rotary evaporated at 80°C and adjusted to neutrality with 4M NaOH. Pipette 150 μL of the hydrolyzate and add 150 μL of 0.6 M NaOH, then add 200 μL of 0.5 M PMP (1-phenyl-3-methyl-5-pyrazolone) methanol solution, and react in a water bath at 70°C for 90 min. After the reaction was completed, it was cooled to room temperature, 0.3 M HCl was added to the reaction solution to adjust to neutrality, and deionized water was added to 1 mL. Add 1 mL of chloroform to extract PMP, centrifuge at 12 000 rpm for 1 min, and repeat the extraction three times. The upper aqueous phase solution was passed through a 0.22 μm aqueous phase filter, and 20 μL was taken on the machine. The derivatized samples were chromatographed on a C18 column with UV detector OD 230 , the mobile phase was a mixed solution of P...

Embodiment 3

[0069] The content of each component of yeast glucan and mannoprotein obtained in Example 1 was determined. Crude protein and ash were measured by AOAC method (1990); total sugar was measured by anthrone-sulfuric acid method; yeast glucan and mannoprotein were measured by referring to Example 2, and quantified by external standard method.

[0070] The results are shown in Table 1. The yeast cells are mainly composed of polysaccharides and proteins, with a total sugar content of 34.32% (wherein, glucan accounts for 20.56% of dry cell weight, and mannan accounts for 13.32%), and protein content is 59.31%. The yield of mannoprotein prepared by the method of the invention is 11.1% and the purity is 90.66%; the yield of yeast glucan is 17.44% and the purity is 85.36%.

[0071] Table 1 Analysis of yeast and zymosan components

[0072]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com