Preparation method of anatase titanium dioxide

An anatase titanium dioxide, anatase technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of high corrosion resistance, polluted environment, multi-operation steps of crystal transformation, etc., and achieves simple and reliable operation. control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

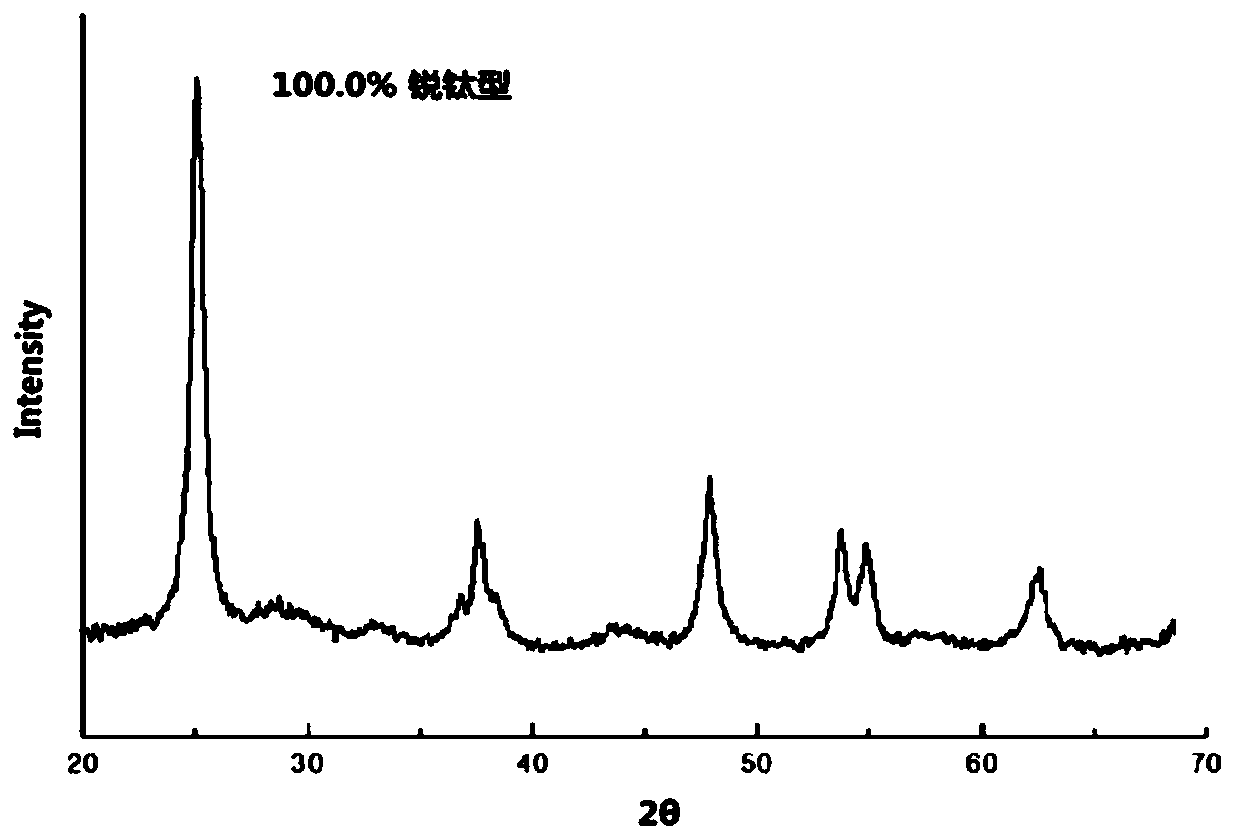

Embodiment 1

[0046] A preparation method of anatase titanium dioxide, comprising the following steps:

[0047] S1. First add sodium sulfate and sodium hexametaphosphate to 100ml of deionized water, and preheat it to 94°C under stirring conditions to obtain a preheated bottom liquid.

[0048] Among them, with SO 4 2- Calculated, the concentration of sodium sulfate in the bottom liquid is 0.5mol / L; 2 o 5 Calculated, the concentration of sodium hexametaphosphate in the bottom liquid is 0.5mol / L.

[0049] S2. Preheat 400ml of titanyl chloride aqueous solution to 94°C, and add it to the preheated bottom water within 17 minutes, continue to heat up to 100°C, keep warm for 2.5 hours, cool and separate by suction filtration to obtain anatase Hydrated titanium dioxide and hydrochloric acid, recovery of hydrochloric acid.

[0050] Among them, TiO 2 Calculated, the concentration of titanyl chloride in the titanyl chloride aqueous solution is 250g / L.

[0051] S3. The anatase-type hydrated titan...

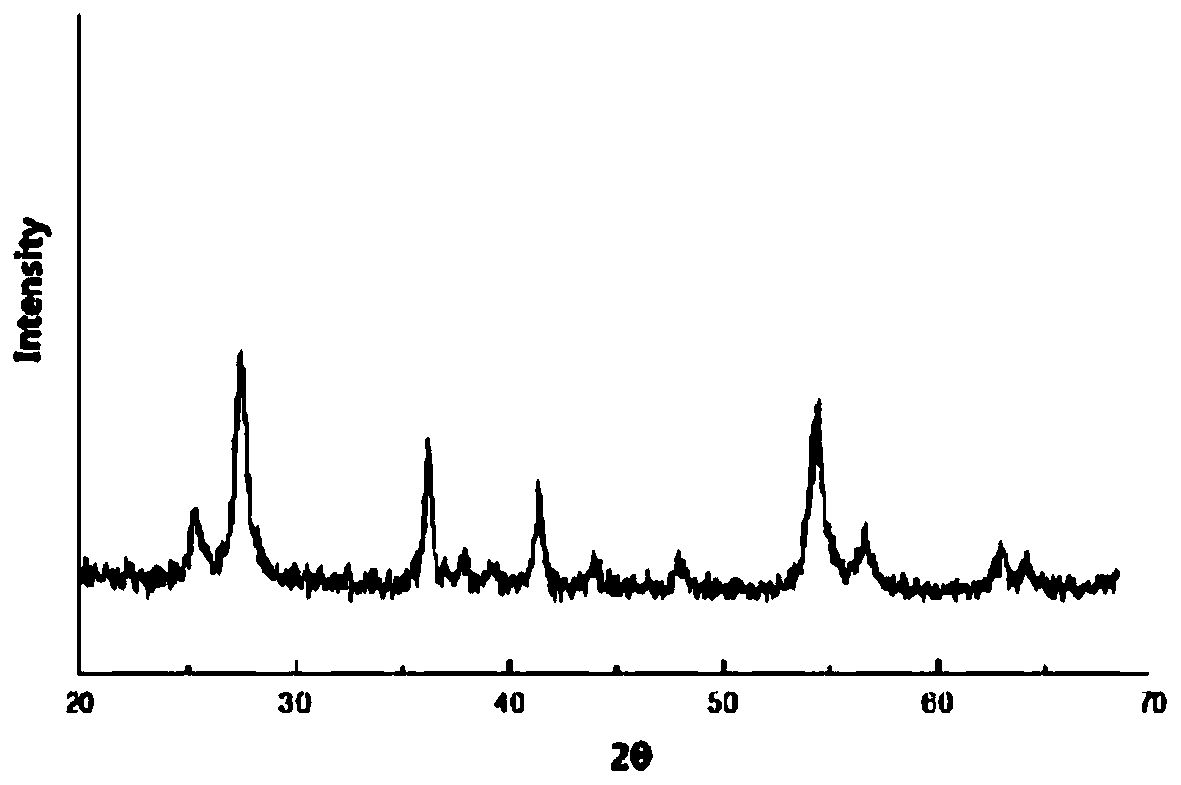

Embodiment 2

[0054] A preparation method of anatase titanium dioxide, comprising the following steps:

[0055] S1. First, add potassium sulfate and sodium pyrophosphate to 100ml of deionized water, and heat it to 100°C with stirring to obtain a preheated bottom liquid.

[0056] Among them, with SO 4 2- Calculated, the concentration of potassium sulfate in the bottom liquid is 0.1mol / L; 2 o 5 The concentration of sodium pyrophosphate in the bottom liquid is 1mol / L.

[0057] S2. Preheat 300ml titanium oxychloride aqueous solution to 90°C, and add it to the preheated bottom water within 15 minutes, continue to heat up to 90°C, keep warm for 2 hours, cool and separate by suction filtration to obtain anatase Hydrated titanium dioxide and hydrochloric acid, recovery of hydrochloric acid.

[0058] Among them, TiO 2 Calculated, the concentration of titanyl chloride in the titanyl chloride aqueous solution is 250g / L.

[0059] S3. The anatase-type hydrated titanium dioxide is subjected to sal...

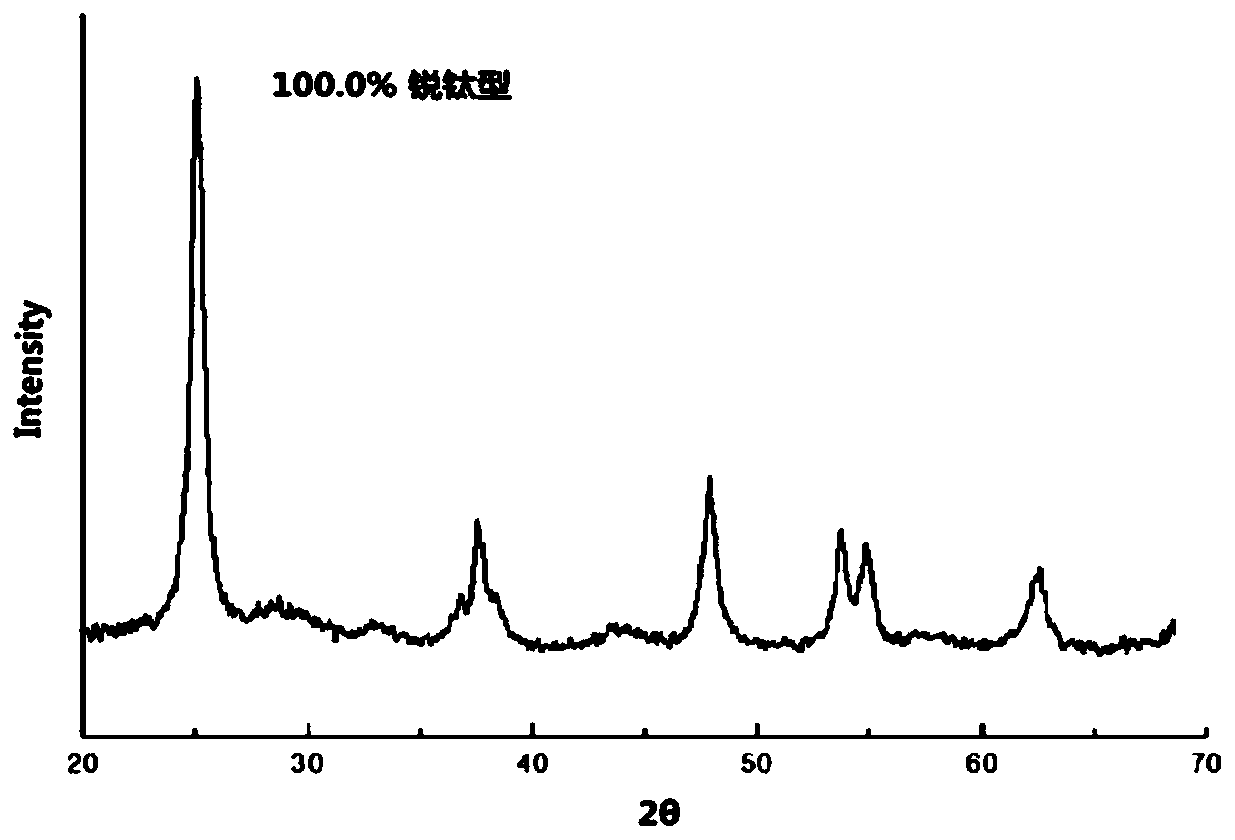

Embodiment 3

[0061] A preparation method of anatase titanium dioxide, comprising the following steps:

[0062] S1. First, add sodium sulfate and sodium orthophosphate to 100ml of deionized water, heat it to 98°C under stirring conditions, and obtain a preheated bottom liquid.

[0063] Among them, with SO 4 2- Calculated, the concentration of sodium sulfate in the bottom liquid is 1mol / L; 2 o 5 Calculated, the concentration of sodium orthophosphate in the bottom liquid is 0.1mol / L.

[0064] S2. Preheat 500ml of titanyl chloride aqueous solution to 98°C, and add it to the preheated bottom water within 20 minutes, continue to heat up to 110°C, keep warm for 3 hours, cool and separate by suction filtration to obtain anatase Hydrated titanium dioxide and hydrochloric acid, recovery of hydrochloric acid.

[0065] Among them, TiO 2 Calculated, the concentration of titanyl chloride in the titanyl chloride aqueous solution is 250g / L.

[0066] S3. Put the anatase-type hydrated titanium dioxid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com