Micro-oxidized conductive carbon black supported nano metal bismuth catalyst and application thereof

A technology of conductive carbon black and nano metal, applied in the field of catalytic chemistry, can solve the problems of low activation ability of nitrogen molecules, lack of practical value, strong competition for hydrogen evolution reaction, etc., and achieve the effect of promoting reaction activity, improving selectivity and wide application prospect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

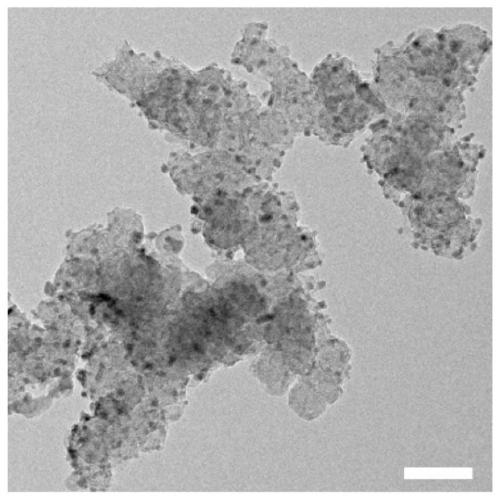

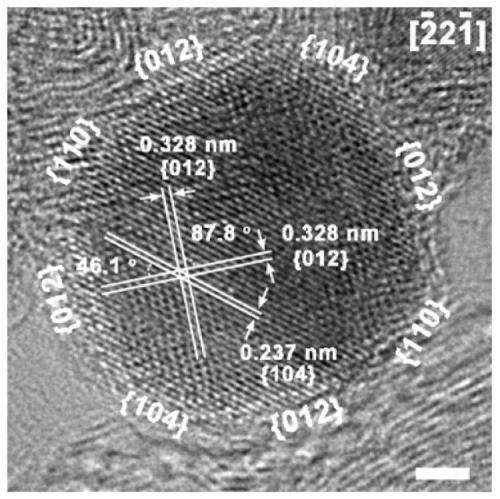

Image

Examples

Embodiment 1

[0040] (1) get 10g conductive carbon black (conductive carbon black uses the acetylene black type conductive carbon black that Alfa company produces), soak and wash three times with hot nitric acid (mass fraction is 20%) of 50-70 degree Celsius, then use deionized water Wash it to neutral and dry it in the shade at room temperature. Take 2 g of the above-mentioned treated conductive carbon black in a three-necked flask, add 80 mL of concentrated sulfuric acid (98% by mass) and stir at room temperature for 12 hours. Subsequently, the three-necked flask was placed in an ice-water bath, and 2 g of ground potassium permanganate powder was slowly added into the three-necked flask, and the whole process lasted for about 1 hour. After the addition was complete, the temperature of the reaction system was raised to 35° C., and the reaction was continued at this temperature for 90 minutes. Subsequently, 160 mL of deionized water was slowly added into the three-necked flask four times, ...

Embodiment 2

[0046] (1) get 10g conductive carbon black (conductive carbon black uses the acetylene black type conductive carbon black that Alfa company produces), soak and wash three times with hot nitric acid (mass fraction is 20%) of 50-70 degree Celsius, then use deionized water Wash it to neutral and dry it in the shade at room temperature. Take 2 g of the above-mentioned treated conductive carbon black in a three-necked flask, add 80 mL of concentrated sulfuric acid (98% by mass) and stir at room temperature for 12 hours. Subsequently, the three-necked flask was placed in an ice-water bath, and 2 g of ground potassium permanganate powder was slowly added into the three-necked flask, and the whole process lasted for about 1 hour. After the addition was complete, the temperature of the reaction system was raised to 35° C., and the reaction was continued at this temperature for 90 minutes. Subsequently, 160 mL of deionized water was slowly added into the three-necked flask four times, ...

Embodiment 3

[0052] (1) get 10g conductive carbon black (conductive carbon black uses the acetylene black type conductive carbon black that Alfa company produces), soak and wash three times with hot nitric acid (mass fraction is 20%) of 50-70 degree Celsius, then use deionized water Wash it to neutral and dry it in the shade at room temperature. Take 2 g of the above-mentioned treated conductive carbon black in a three-necked flask, add 80 mL of concentrated sulfuric acid (98% by mass) and stir at room temperature for 12 hours. Subsequently, the three-necked flask was placed in an ice-water bath, and 2 g of ground potassium permanganate powder was slowly added into the three-necked flask, and the whole process lasted for about 1 hour. After the addition was complete, the temperature of the reaction system was raised to 35° C., and the reaction was continued at this temperature for 90 minutes. Subsequently, 160 mL of deionized water was slowly added into the three-necked flask four times, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Current density value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com